THREAD: Vaccine Manufacturing

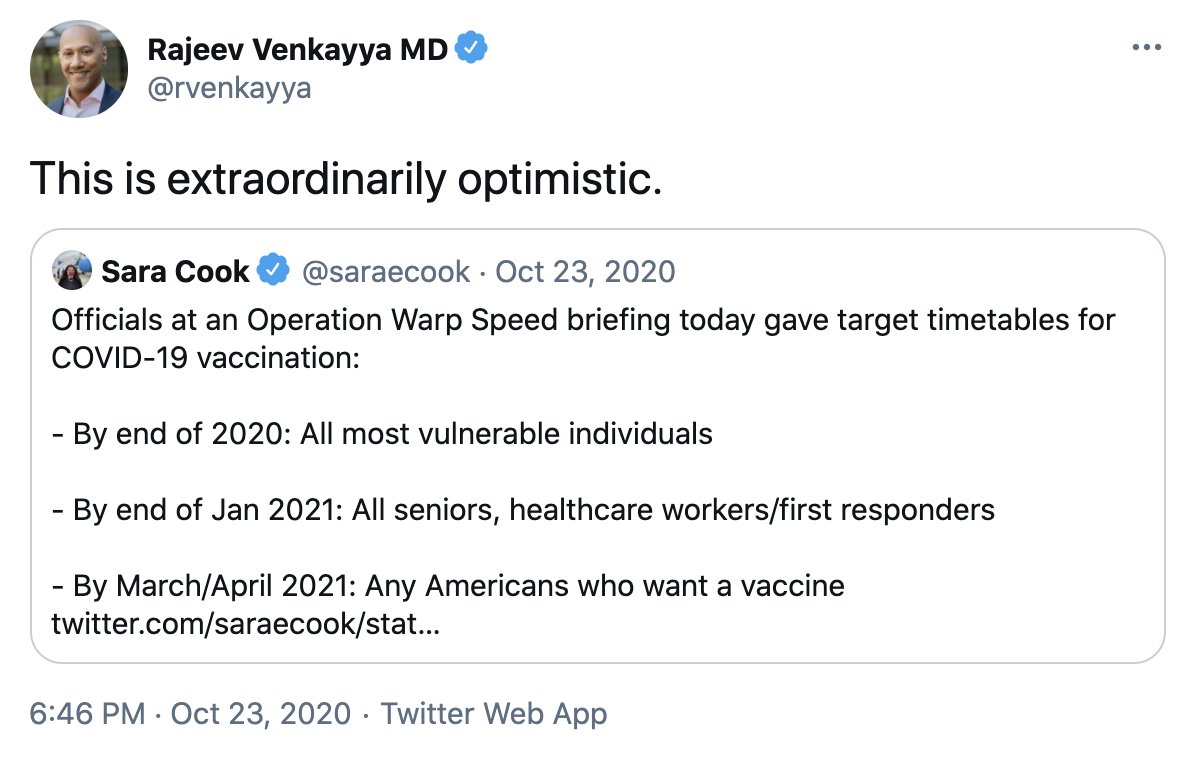

Back in October, I said the Warp Speed timelines were extraordinarily optimistic given the inherent risks of vaccine development, manufacturing and distribution. All of those risks and others have materialized. 1/

https://twitter.com/rvenkayya/status/1320022543076630529?s=20

Back in October, I said the Warp Speed timelines were extraordinarily optimistic given the inherent risks of vaccine development, manufacturing and distribution. All of those risks and others have materialized. 1/

https://twitter.com/rvenkayya/status/1320022543076630529?s=20

Much of the risk is in "scaling up" production to produce large volumes of vaccine in a facility, and “scaling out” to manufacturing partners to expand capacity. This thread is about vaccine manufacturing and the challenges we’ll continue to face. 2/ https://twitter.com/rvenkayya/status/1346815419810799617?s=20

This article from @lizszabo & colleagues is one of the few I've seen that attempts to capture the complexity and risk of manufacturing and explain why supply bottlenecks can't be resolved overnight. 3/ @SJTribble @ArthurAllen202 @JayHancock1 @KHNews https://khn.org/news/article/ramping-up-covid-vaccine-production-could-take-months-even-with-bidens-best-tool-to-pressure-companies/

Two things drive much of this complexity: (1) vaccines are complex biologics that are difficult to characterize the way we do most drugs; and (2) it’s hard to predict whether changes to the vaccine or manufacturing process will impact vaccine efficacy or safety. 4/

This is why we say “the process is the product,” and avoid making significant changes to the process after Ph3 efficacy is shown. If changes are necessary, extensive testing is needed to “bridge” to the Ph3 process, and regulatory approval of those changes is necessary. 5/

This is an area where correlates of protection can be very helpful, beyond their value in assessing “second wave” vaccines. 6/ https://twitter.com/rvenkayya/status/1326876443968757760?s=20

The tests (assays) used to characterize the vaccine are just as important as the process itself, but they are also complex. Technical hurdles to assay development or problems with assay performance can have a huge impact on manufacturing and timelines. 7/

Biology drives more complexity. Many vaccines are made by growing viruses in cells, and when that doesn’t happen as expected, it can lead to losses in production and delayed timelines. This is an area where cell- and virus-free mRNA vaccine production has a major advantage. 8/

For these reasons, every aspect of vaccine manufacturing is tightly controlled: raw materials, equipment, production processes, training, operating procedures etc. All of it happens under GMP (Good Manufacturing Practice) regulations, and facilities are regularly inspected. 9/

It’s estimated that 70% of manufacturing time is spent on quality control, and it’s not uncommon for issues that arise to delay the supply of vaccines to immunization programs. While these risks can go down with time and experience with a given product, they never go away. 10/

All of these challenges carry over to manufacturing partnerships for capacity expansion. Depending on the process complexity, infrastructure, and experience of the partners (on both sides), technology transfers can take several months and carry technical and timeline risks. 11/

Partnerships that started last year should contribute supply in the near future. But a partnership that starts today will take time to deliver vaccine doses due to the complexity, constraints and risks described above. 12/ https://twitter.com/rvenkayya/status/1346815818483576832?s=20

The most experienced vaccine manufacturers face manufacturing issues in the course of normal business, and that risk is only amplified in the pandemic context given the urgency and timeline pressures. 13/

We will continue to experience supply delays but should view that as the system working to ensure that all vaccines delivered meet the highest standards of quality & safety and perform as expected. 14/

It's essential to expand capacity to achieve global equitable access. But this has to be done in a way that ensures quality & consistency of those vaccines, and doing it right takes time, experience, resources and a sophisticated understanding of risk and how to manage it. 15/

Many thanks to our former COO and current CEO of Reliance, @rsinghvi, for teaching me a lot about CMC and manufacturing and for his sanity check on this thread! 16/

Read on Twitter

Read on Twitter