Let's talk materials: Co, Zn. Copper roofing is the original green roof. Copper, like gold, is a survivor: about 80% of all the copper ever mined is still in use today. The only roof material that can be fully recycled, and as metal prices rises, always at a substantial profit.

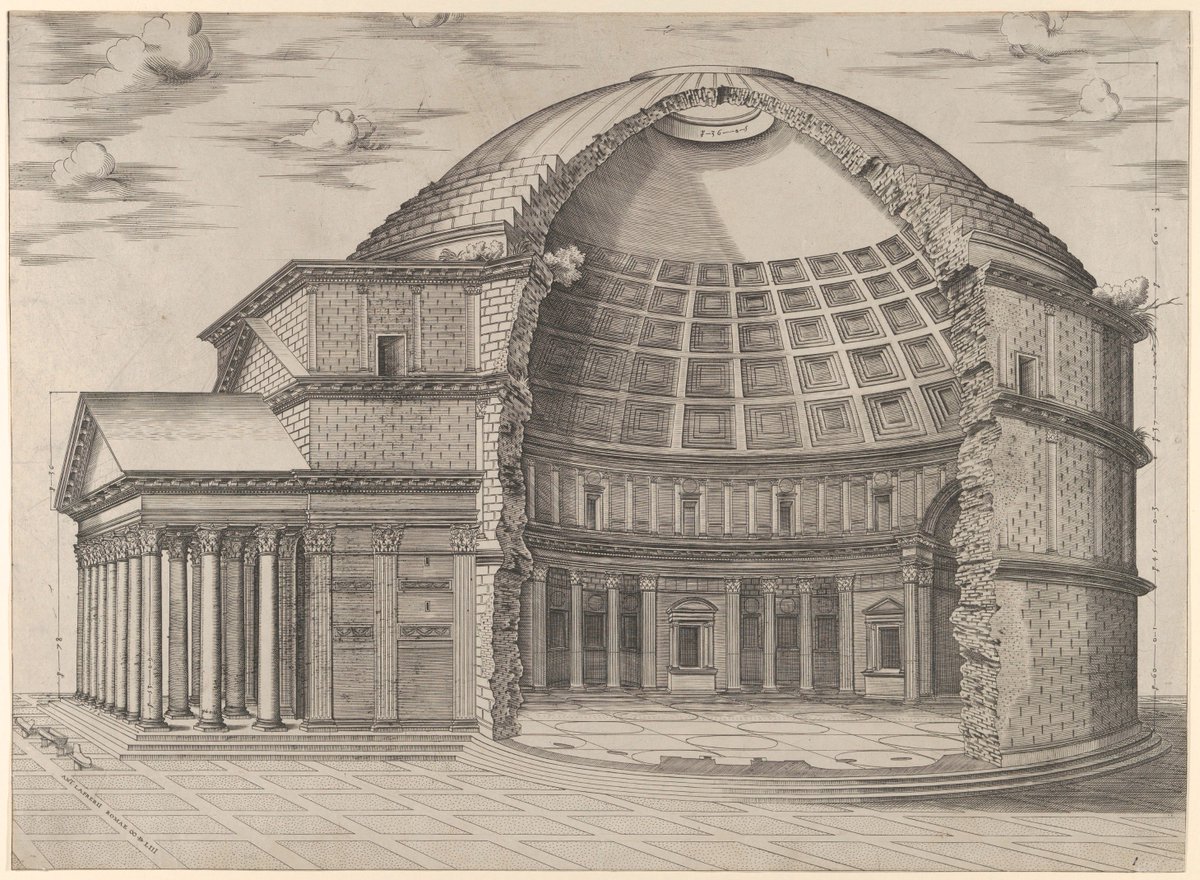

The 200 tons of copper plate used by the Romans on the Pantheon roof survived until Pope Urban VIII took them down for recycling in the first half of the 17th century. That is about 1500 years. Quite the lifespan.

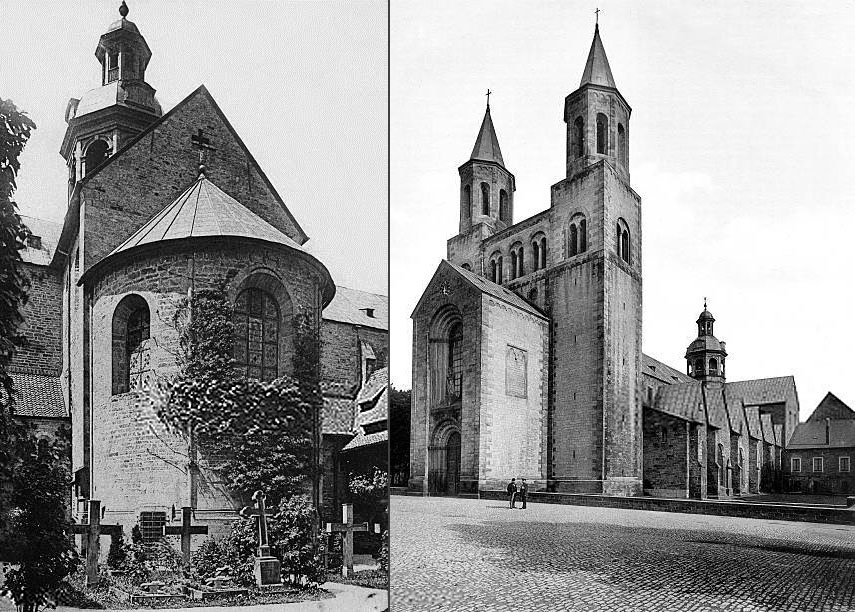

The copper roofing of Hildesheim Cathedral was installed in 1280 and survived until the British RAF decided to destroy it in 1945. 665 years. But the Tausendjähriger Rosenstock (from A.D. 815) survived.

The copper roofing on Kronborg Castle in Denmark was installed in 1585, it survived until 2009. That is 424 years, but a few parts are still intact. Not a bad run for roofing. This castle owe much of its worldwide fame to the play Hamlet.

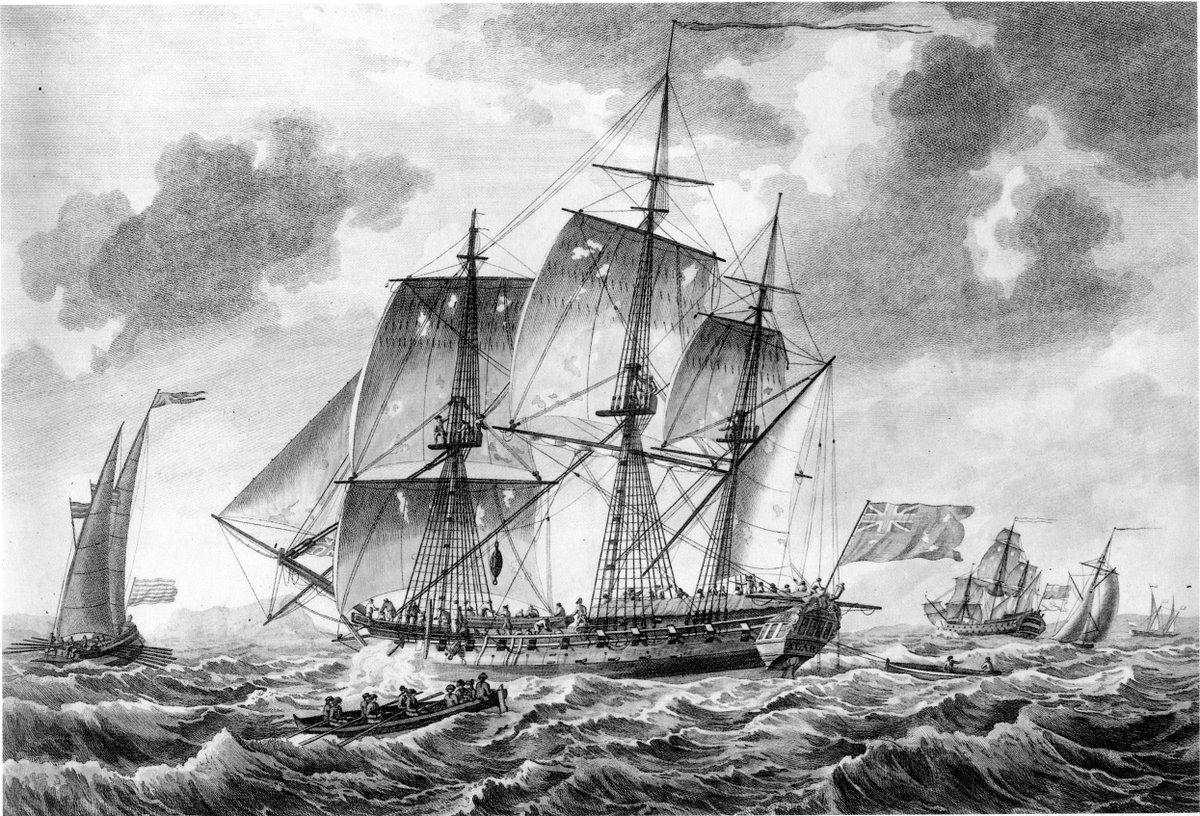

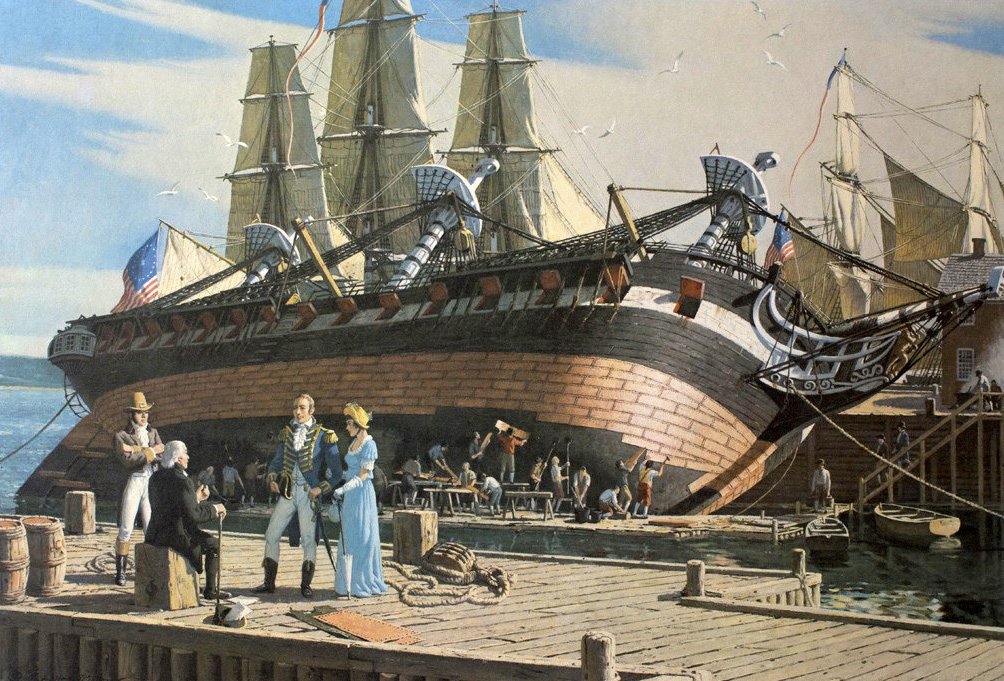

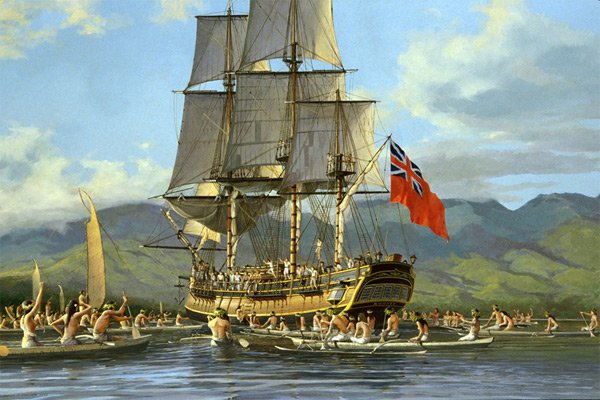

Copper played a role also in naval architecture. Copper sheeting for wooden ships was a huge improvement during the Age of Sail. In 1761 the HMS Alarm was the first ship to be completely sheeted in copper. Copper repels biofouling, barnacles.

The copper stopped shipworm from destroying the wooden hull, vastly increasing the life span of the ships of the time. This innovation alone saved entire forests from extinction as the life span of ships expanded exponentially. Here's the USS Constitution.

It also meant that ships would go faster (up to 10%), would be more maneuverable in storm and combat, and could spend far more time in actual use rather than in dry dock for repairs. It made naval access to the tropics economical and realistic.

The HMS Bounty was famously copper plated to prepare her for her mission to the South Pacific. Incidentally her Captain, William Bligh, was a Lieutenant by rank.

Back to architecture, copper roofing is one of the oldest, best known, well researched, materials we have, it has been used all over the world for thousands of years. Just like in Europe, the Japanese used copper to imitate earlier traditional materials.

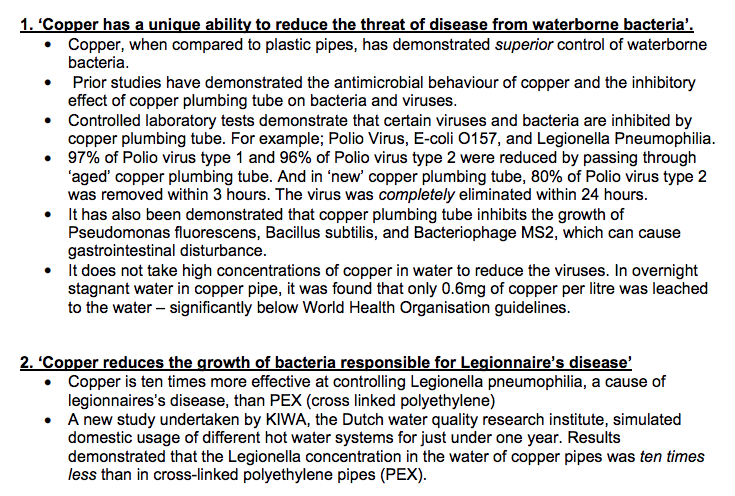

Architecturally, copper and brass is also useful inside our buildings. It has an anti-microbial property that has been known for ages. Barracks, hospitals favored copper and brass for handles and door knobs because they kill germs within minutes: http://www.telegraph.co.uk/news/health/news/9762689/Fit-brass-fixtures-to-cut-superbugs-say-scientists.html

Another bonus is that copper and brass look terrible when touched, so it is easy to motivate soldiers, sailors, cleaners and nurses to keep them shiny clean at all time, further reducing the spread of bacteria and disease.

Compare copper with the materials favored by us moderns: dirty, non-sustainable, difficult to recycle and plain ugly. A copper roof is something that you won't just hand down to your children, but to your great grand children.

A roofer I know: "No one can see the details of my work but in a a couple of centuries when they take this roof down some craftsman will see it and I don't want him to think the men who built this were lazy or didn't understand the material."

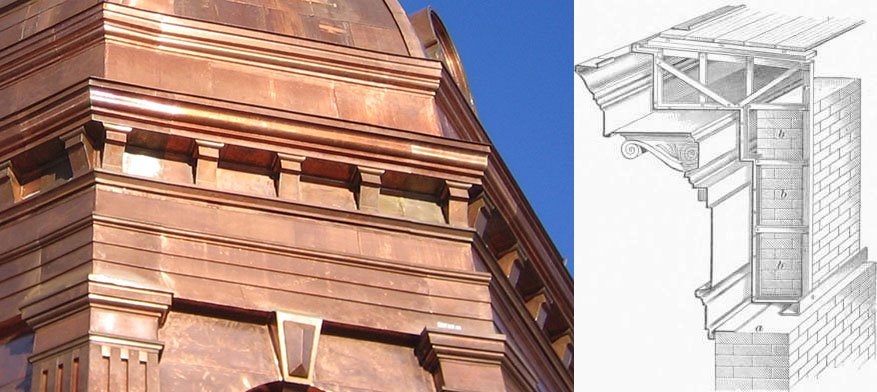

Danish video from Aarhus Old Town: construction of a zinc covered cupola for a tower. When we build for the ages and posterity these details are not only beautiful but also makes economical and structural sense: protecting the building from the elements.

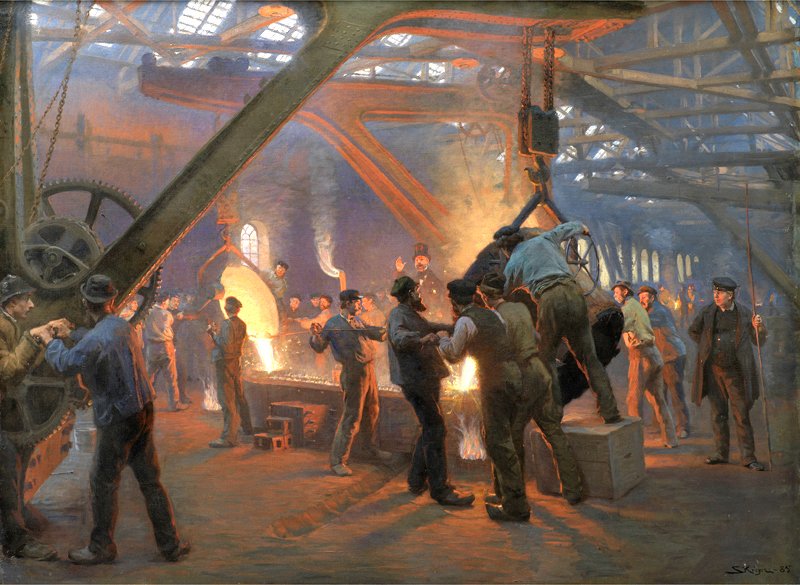

Another curious connection between copper and architecture is found in the production of copper. Smelting copper (and other metals of course) resulted in huge heaps of by-products, slag. In the 18th century the idea came to pour the slag into forms, creating slag bricks.

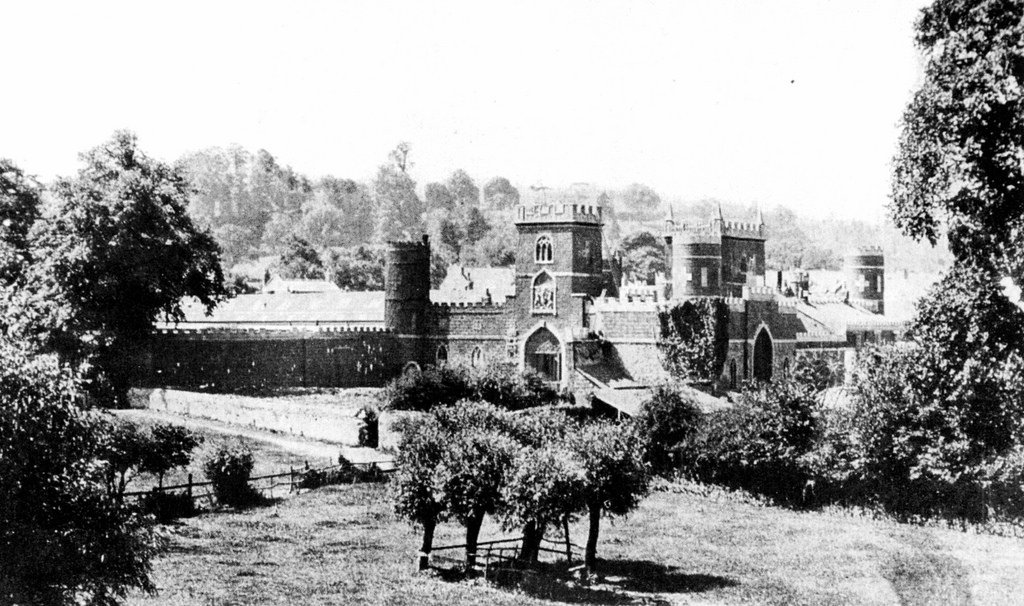

The material was free and labor was plentiful, so in England the copper producing areas saw quite a few follies built with copper slag bricks. The most famous is the 1755 Black Castle in Bristol, once used as stables and offices, today a pub. The bricks still look brand new.

In the 19th century many houses around Britain were built with copper-slag bricks, but it was especially useful for spots that required the very hardest material: quoins, foundations, roadwork, etc. Much of it remains, but is covered in stucco and can be tricky to find.

But the Kings of copper slag and iron slag brick building were the Swedes. In the mining provinces of Sweden and southern Finland you will find absolutely stunning use of this industrial by-product. Here is the Fiskars factory area in Finland! Note the beautiful mix of materials.

Here is a beautiful iron-slag brick church in Boxholm, Sweden. Note how much cleaner the bricks are compare to the more irregular copper-slag bricks. Of course, these are exceptionally durable, far stronger than stone or clay brick. Built by hand in 1897 from 200 000 bricks.

In Avesta, Sweden, a gorgeous school designed to house 180 children of workers at the local foundries, built by hand in 1880. The architect Adolf Kjellström (1832-1932) designed many charming Gothic Revival school buildings. inspired by many visits to England.

At Strömsberg, in Tierp, Sweden the coal houses were built in slagg bricks, this is one the few remaining coal houses (as everywhere, few purely industrial auxiliary buildings remain in the world), built in 1830 or 1850.

The production of slag brick stopped completely in the 1960s when the furnace coal was replaced by coke: it produced brittle bricks that cracked as soon as it cooled. However, there are numerous buildings made by slag splinters, the rough unformed by-products, from 17th-19th c.

In Smedjebacken, Sweden, this train engine stall was made by rough slag splinter. Most buildings would have been rendered, but these industrial buildings were left uncovered, luckily for us. The walls look brand but are 143 years old. Quite the lifespan.

If you find an old slag heap you can try building with the material, or slag bricks can be recycled. Unlike bricks they are water impervious so it is best to use cement mortar and build thicker walls (20") for stability. Especially useful in foundations, exceptionally strong.

Bonus: the gorgeous granary in Nyhammar, Sweden, built in the unique Forsgrenska style of architecture using slag splinters, the style is only found in industrial and agricultural buildings in Västerbergslagen in Sweden, named after its originator, Olof Forsgren (1774-1862).

In Japan, where weather can be severe and sea mist can rot any building facade in a few years entire buildings are sometimes clad in copper.

The durability, flexibility and strength of copper sheeting makes it the ideal material to use instead of stone for architectural details, such as cornices, flashing, brackets, friezes, cresting, spires etc.

Inspired/reminded by this beautiful 1906 essay by Hilaire Belloc, I think it is time to talk about copper in the kitchen! https://twitter.com/wrathofgnon/status/1151789137092943872?s=20

Copper is hands down the best material for kitchen ware: it has twice the thermal conductivity of aluminum 5 times that of cast iron and 25 times that of stainless steel. This means it heats up faster (requiring far less use of gas or electricity) and more evenly, better cooking!

Cooking with copper becomes even more environmentally friendly when you consider the amount of energy it takes to mine and process copper: less than half of that of stainless steel & a mere third of aluminum, & it is fully recyclable, 80% of all copper ever mined is still in use.

And unlike nonstick pans (which lasts 3-5 years, releases toxins during production and use and can't be fully recycled...) your copper pans can be in daily use for centuries (the thicker they are the better they work the longer they last the more valuable they get).

Copper kitchenware needs a little bit more finesse in the kitchen, and retinning every now and then (as in Belloc's essay). I have never done it myself but the process looks like great fun and a great manual skill. Human scaled industry. https://vimeo.com/205381935

You can keep buying teflon non-stick pans that will poison both you and the environment and become worthless after 3-5 years or you can pay a little more for copper that will NEVER lose value (antiques!) and is so gorgeous you can decorate your kitchen with it! What will it be?

Read on Twitter

Read on Twitter