Battery materials and recycling

and recycling prompt some of the most frequently asked questions about electric vehicles. Here’s a new factsheet from @UCSUSA addressing some of these questions. Takeaways below: https://ucsusa.org/resources/ev-battery-recycling

prompt some of the most frequently asked questions about electric vehicles. Here’s a new factsheet from @UCSUSA addressing some of these questions. Takeaways below: https://ucsusa.org/resources/ev-battery-recycling

and recycling

and recycling prompt some of the most frequently asked questions about electric vehicles. Here’s a new factsheet from @UCSUSA addressing some of these questions. Takeaways below: https://ucsusa.org/resources/ev-battery-recycling

prompt some of the most frequently asked questions about electric vehicles. Here’s a new factsheet from @UCSUSA addressing some of these questions. Takeaways below: https://ucsusa.org/resources/ev-battery-recycling

(1) There’s a lot at play with battery materials: supply/demand, geopolitics, human rights, water supplies, technological innovation, etc.

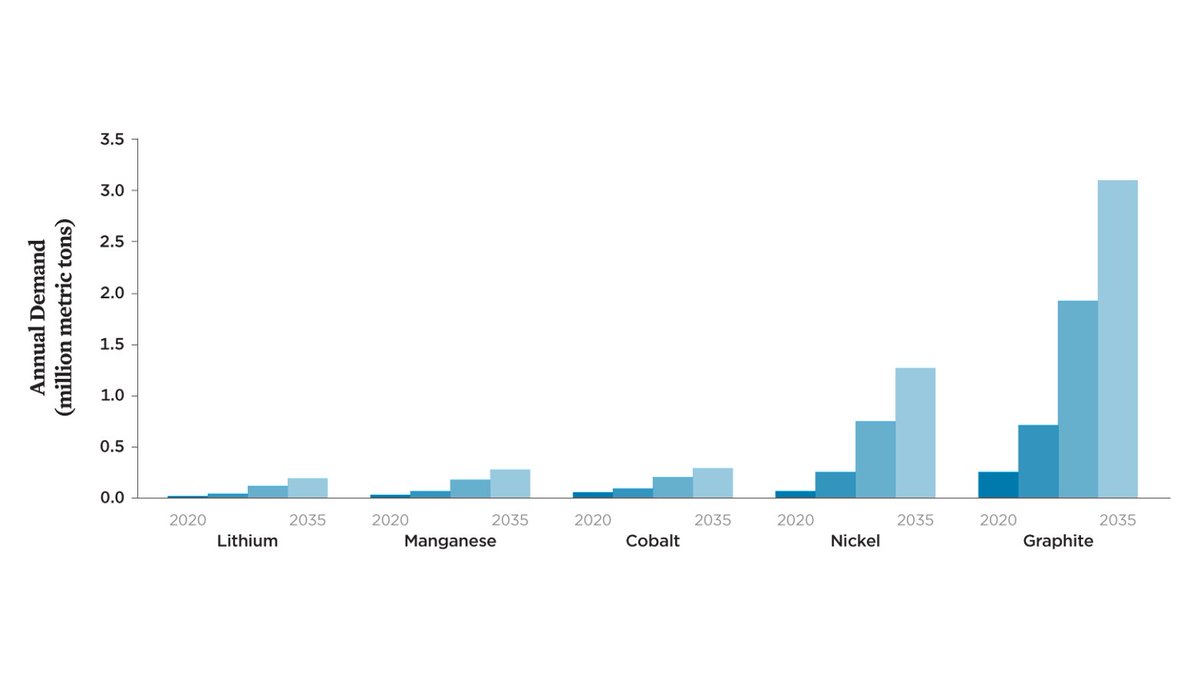

Demand for battery materials will continue to increase (obvi). The exact amount depends on new vehicle demand and policy targets for EVs.

Batteries make up a large fraction of demand for some materials (e.g. Li, Co), whereas other industries (e.g. steel) drive demand for Ni and Mn.

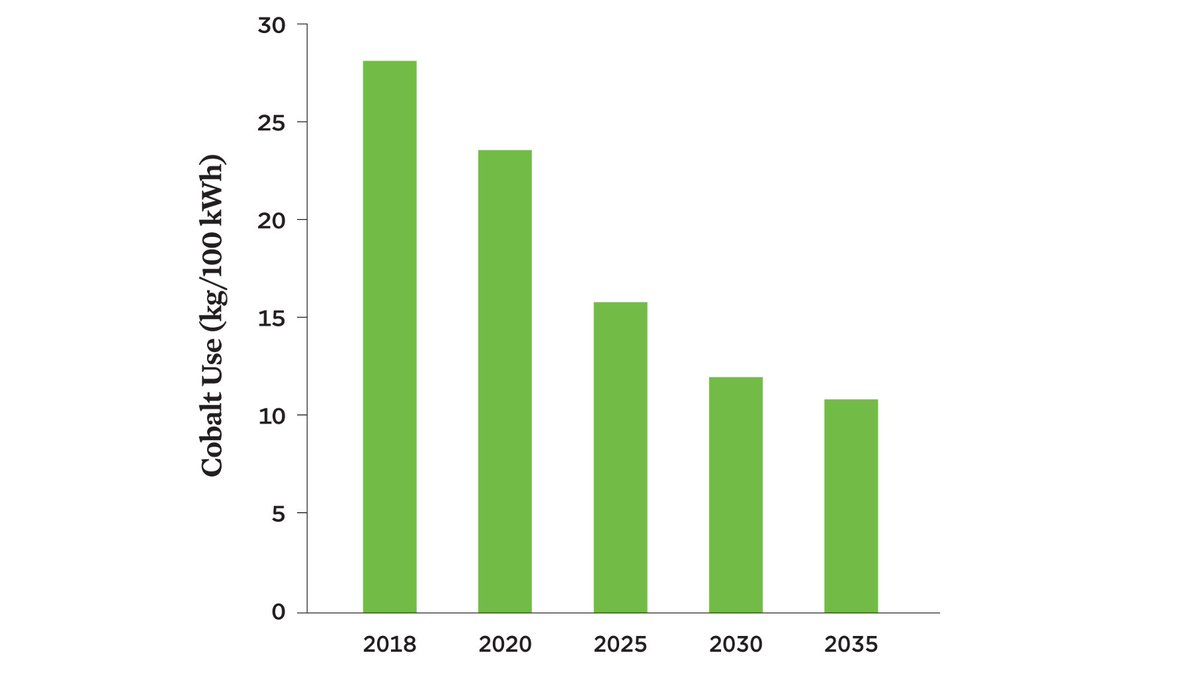

The shift from high cobalt to low/no cobalt chemistries is real. Driven by the cost of cobalt and performance/durability considerations.

The shift in battery demand from consumer electronics (still use high cobalt chemistries) to electric vehicles contributes to the cobalt per kWh. Not shown is the corresponding increase

cobalt per kWh. Not shown is the corresponding increase in the amount of nickel in batteries.

in the amount of nickel in batteries.

cobalt per kWh. Not shown is the corresponding increase

cobalt per kWh. Not shown is the corresponding increase in the amount of nickel in batteries.

in the amount of nickel in batteries.

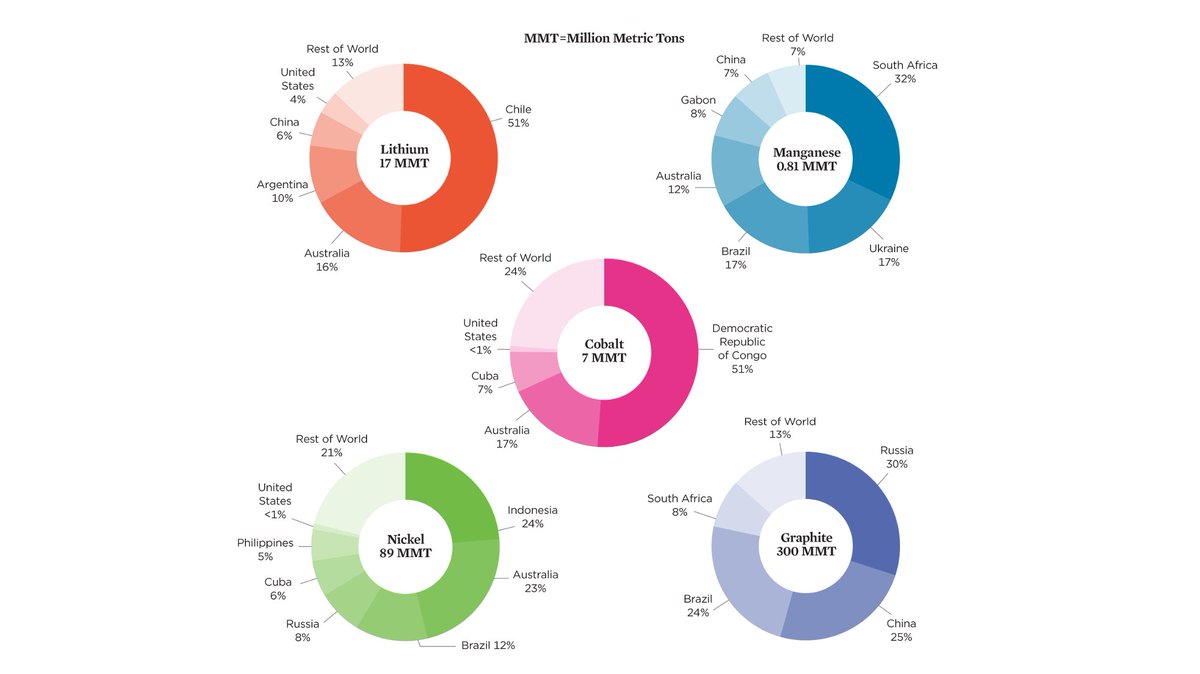

Materials used in batteries are relatively abundant in the Earth’s crust (estimated reserves shown below). But there could be bottlenecks in the supply of processed materials in the next decade, esp. if there aren’t clear signals for EV demand.

While reserves are somewhat geographically concentrated, processing of these minerals is even more concentrated (in China).

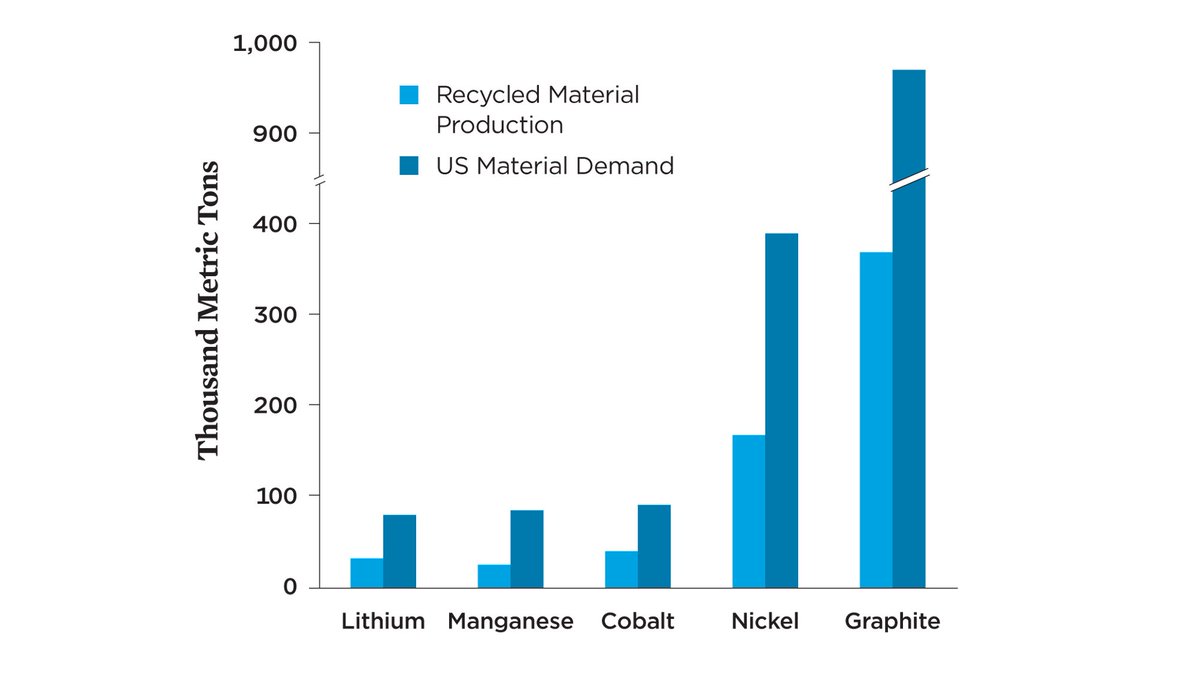

(2) Recycling *could* meet a measurable chunk of demand for battery materials as more EVs come on/off the road, e.g., 30% or more of material demand in 2035 for the scenario considered in the factsheet.

But a lot needs to happen to get there. Battery collection rates, metal recovery rates, and growth of the EV market are key variables in the amount of recycled content we achieve.

E.g., even at high collection and recovery rates, there will be a lag between number of EVs coming off the road as coming on as EV adoption grows.

((Numbers in our analysis reflect the passenger EV adoption scenario in BNEF’s 2019 EV Outlook, e.g. 6.2 million full BEVs out of 16.1 million total US passenger vehicle sales in 2035. Admittedly, this is much less than 100% sales by 2035!))

General conclusions ~hold at different rates of EV adoption but not material quantities.

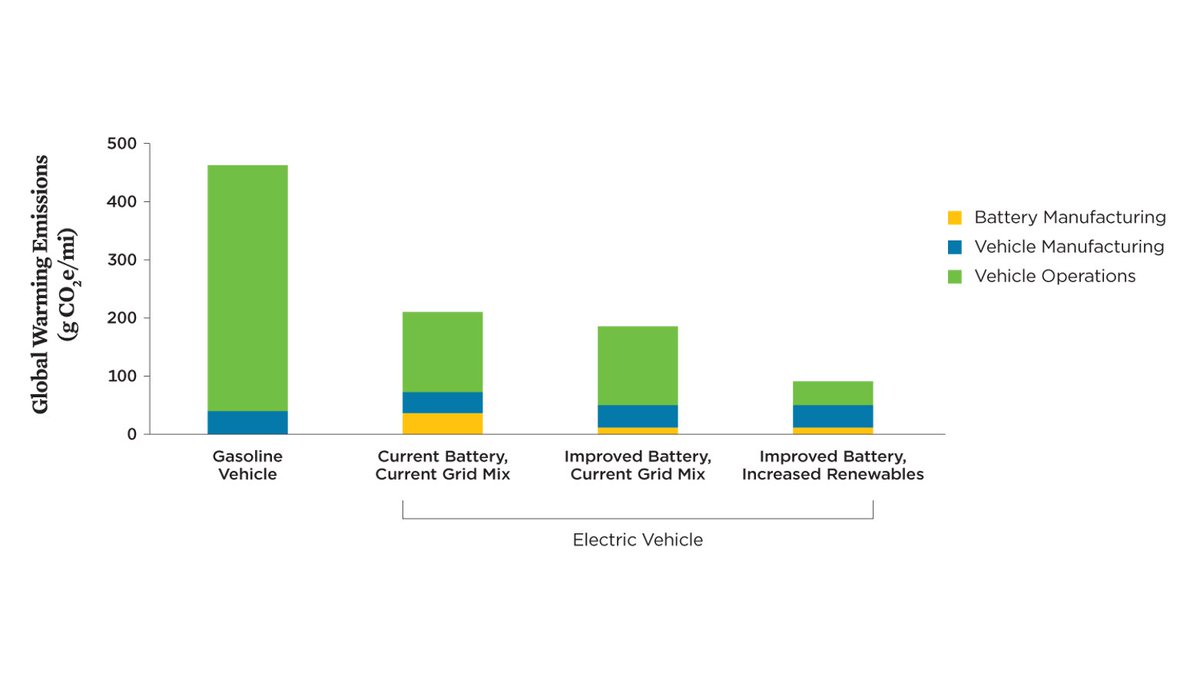

(3) Recycling can lower GHG emissions further, but renewable electricity for vehicle charging is still the biggie. Renewable electricity for battery manufacturing helps lower emissions too.

(4) We need policies to minimize the impacts of mining and enable recycling, e.g.:

Standards for recycled content in EV batteries

Standards for recycled content in EV batteries

Waste management policies that enable safe transport and handling of used EV batteries

Waste management policies that enable safe transport and handling of used EV batteries

Standards for labeling (e.g. chemistry, cycle history)

Standards for labeling (e.g. chemistry, cycle history)

Standards for recycled content in EV batteries

Standards for recycled content in EV batteries  Waste management policies that enable safe transport and handling of used EV batteries

Waste management policies that enable safe transport and handling of used EV batteries Standards for labeling (e.g. chemistry, cycle history)

Standards for labeling (e.g. chemistry, cycle history)

If we want batteries to be recycled in the US, we need battery manufacturing in the US. Outside of @Tesla, not much happening here today or even in the near future. See @JeanneWhalen article from yesterday: https://www.washingtonpost.com/technology/2021/02/11/us-battery-production-china-europe/

A decent amount of policies are in motion, lots abroad but some in US.

The European Commission recently *proposed* measures requiring the collection of used batteries and to set standards for recycled content in new batteries. https://ec.europa.eu/commission/presscorner/detail/en/ip_20_2312

The European Commission recently *proposed* measures requiring the collection of used batteries and to set standards for recycled content in new batteries. https://ec.europa.eu/commission/presscorner/detail/en/ip_20_2312

The Senate’s Energy 'n Natural Resources Committee has explored battery materials in several hearings over the last three years, mostly in the context of resource availability/security:

https://www.energy.senate.gov/hearings/2017/10/full-committee-hearing-to-examine-energy-storage-technologies, https://www.energy.senate.gov/hearings/2019/2/full-committee-hearing-to-examine-the-outlook-for-energy-and-minerals-markets-in-the-116th-congress, https://www.energy.senate.gov/hearings/2020/6/full-committee-hearing-on-the-impact-of-covid-19-on-mineral-supply-chains

https://www.energy.senate.gov/hearings/2017/10/full-committee-hearing-to-examine-energy-storage-technologies, https://www.energy.senate.gov/hearings/2019/2/full-committee-hearing-to-examine-the-outlook-for-energy-and-minerals-markets-in-the-116th-congress, https://www.energy.senate.gov/hearings/2020/6/full-committee-hearing-on-the-impact-of-covid-19-on-mineral-supply-chains

. @CalRecycle is halfway through a 2-year effort to produce policy recommendations to the California state legislature to enable “as close as possible” to 100% reuse or recycling of EV batteries: https://calepa.ca.gov/climate/lithium-ion-car-battery-recycling-advisory-group/

In all, I’m encouraged by the attention given to battery materials and recycling. But, a lot needs to happen to achieve a sustainable supply chain and the level of recycling we need.

Read on Twitter

Read on Twitter