There’s a bit more back story that's probably worth having in the public domain re AZ/Ox vaccine supply to UK & EU.

These

explained the tech & funding.

explained the tech & funding.

Some are saying ‘a contract (re dose allocation ) is a contract’ – but there’s more to it than meets the eye... 1/ https://twitter.com/sandyddouglas/status/1355565609434677255

These

explained the tech & funding.

explained the tech & funding. Some are saying ‘a contract (re dose allocation ) is a contract’ – but there’s more to it than meets the eye... 1/ https://twitter.com/sandyddouglas/status/1355565609434677255

I haven’t seen the AZ-EU/AZ-UK contracts. They may be unwise, I don’t know.

What I do know is that in Mar, I & my team @JennerInstitute developed what became the UK supply chain (and India/China). In Apr, *before AZ deal*, @GovUK Vacc Taskforce wanted a plan for UK supply. 2/

What I do know is that in Mar, I & my team @JennerInstitute developed what became the UK supply chain (and India/China). In Apr, *before AZ deal*, @GovUK Vacc Taskforce wanted a plan for UK supply. 2/

@GovUK backed that with £65m. It was formally announced later, after the AZ deal on 15 May, but @GovUK funding for us @UniOfOxford to do this was agreed in April. 3/ https://www.ox.ac.uk/news/2020-05-18-funding-and-manufacturing-boost-uk-vaccine-programme

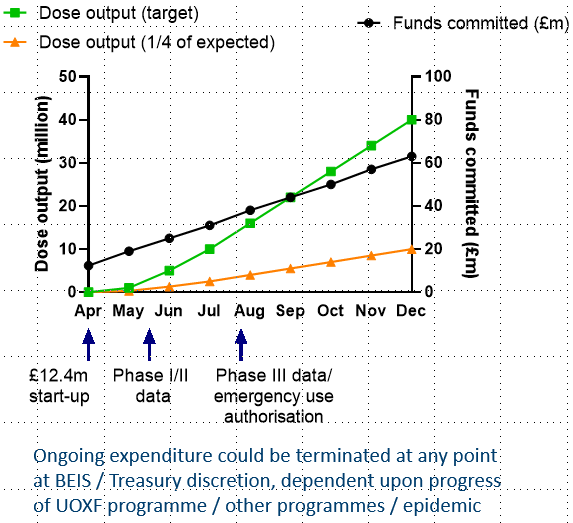

I was v careful in my ‘pitch’ to show the range of uncertainty. Yields per litre have turned out to be at the lower end of what we hoped for in April – at the level to enable output on the orange line in the above. That’s science. Yields were tho within the range I suggested 4/

The Apr plan used manufacturing in 200 litre batches. We knew it wouldn't be enough to supply EU/world, but it seemed crazily ambitious at the time. The tech was brand new (call it 'Process X’). Pre-pandemic we’d only tried a scale 7000x smaller (about 2 tblespns/100 doses). 5/

Understandably I think, @GovUK Vaccines Taskforce’s primary aim was UK supply. But I always referred to the '200 litre'/'Process X' plan as ‘Stream 1’. Even before that was agreed, we started work on ‘Stream 2’. ‘Stream 2’ aimed to enabled export for EU & global supply. 6/

'Stream 2'/ global supply required scaling up even more, to 1000L or more– and that needed an even newer manufacturing technique, that in April we'd only just invented & hadn’t yet shown could work at all (let’s call it ‘Process Y’). 7/

Once AZ joined, they initially kept going with ‘Stream 1’/ ‘Process X’ for UK. But once we knew ‘Stream 2’/ ‘Process Y’ could work, it was decided to use the larger-scale ‘Process Y’ everywhere, so everyone got identical product, and to let us make more of it. 8/

What’s more, the original ‘Stream 1’ plan involved the @GovUK funding a Dutch contractor to supply UK. It turns out that wouldn’t have been hugely popular. By switching to ‘Stream 2’, we enabled the EU sites to focus on supplying the EU. 9/

As @adamjohnritchie explained in his thread, setting up a new process is complex, uncertain & time consuming. 10/ https://twitter.com/adamjohnritchie/status/1355136430402580482

The thing I think is most relevant to EU argument is that ALL suppliers, including UK, stopped work on ‘Process X’ and had to re-learn ‘Process Y’ – so the aim to supply EU/world actually temporarily delayed and increased the risks in fulfilling the UK supply contract. 11/

Where we are now isn’t perfect (per litre, Process Y is still more like the orange line than the green in graph above). That’s why AZ haven’t yet made as much as hoped for from ‘Stream 2’ in UK or EU (along with it taking longer than hoped for to get Belgian factory going). 12/

As I say, I can’t comment on AZ’s contracts. But in considering the right resolution of the problem, I think it’s important to understand: 13/

@GovUK didn't just fund the much-discussed ‘butchers’ shop’ (as I explained  ) – but in fact we had to shut down the UK shop for refurbishment for some months so we could end up in a better position now, and to let us stop importing from the Dutch shop. https://twitter.com/sandyddouglas/status/1355565617731010564

) – but in fact we had to shut down the UK shop for refurbishment for some months so we could end up in a better position now, and to let us stop importing from the Dutch shop. https://twitter.com/sandyddouglas/status/1355565617731010564

) – but in fact we had to shut down the UK shop for refurbishment for some months so we could end up in a better position now, and to let us stop importing from the Dutch shop. https://twitter.com/sandyddouglas/status/1355565617731010564

) – but in fact we had to shut down the UK shop for refurbishment for some months so we could end up in a better position now, and to let us stop importing from the Dutch shop. https://twitter.com/sandyddouglas/status/1355565617731010564

Kudos to my amazing team including Carina Joe, Lee Li, Sofiya Fedosyuk, Gaurav Gupta, @adamjohnritchie, Ram Segireddy, Adam Berg, Iona Tarbet, our partners including Jon Humphreys, @cso_cobrabio, Dennis Verbart, and Richard Turner, Per Alfredsson & teams @AstraZeneca.

And if you're interested in the world outside the EU, here's another thread... https://twitter.com/sandyddouglas/status/1355838692561211393

Read on Twitter

Read on Twitter