#AeroIndia2021 Thread.

When Airshows world over are getting cancelled, Aero India is going ahead with a shorter version focused on business side. I have no doubt, it is going to be a success with all the precautions and measures in place.

Though its not ideal this time for

When Airshows world over are getting cancelled, Aero India is going ahead with a shorter version focused on business side. I have no doubt, it is going to be a success with all the precautions and measures in place.

Though its not ideal this time for

non-biz visitors like me, I am looking forward to the virtual platform. It looks cool and I hope it will be continued for all the future events too. No Aero India Technical Seminars, which is a bummer though.

Anyway, let the show begin.

Anyway, let the show begin.

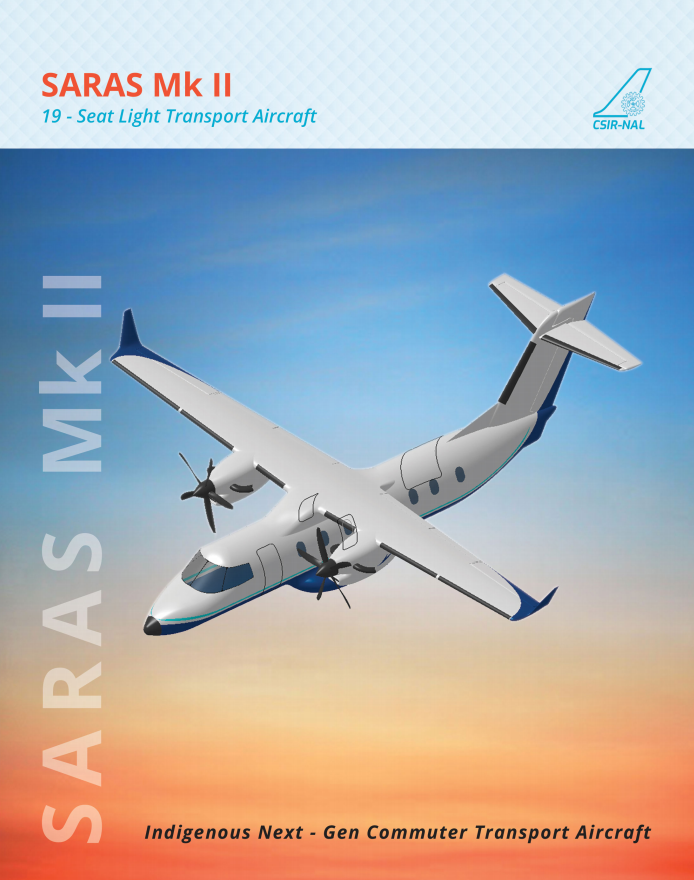

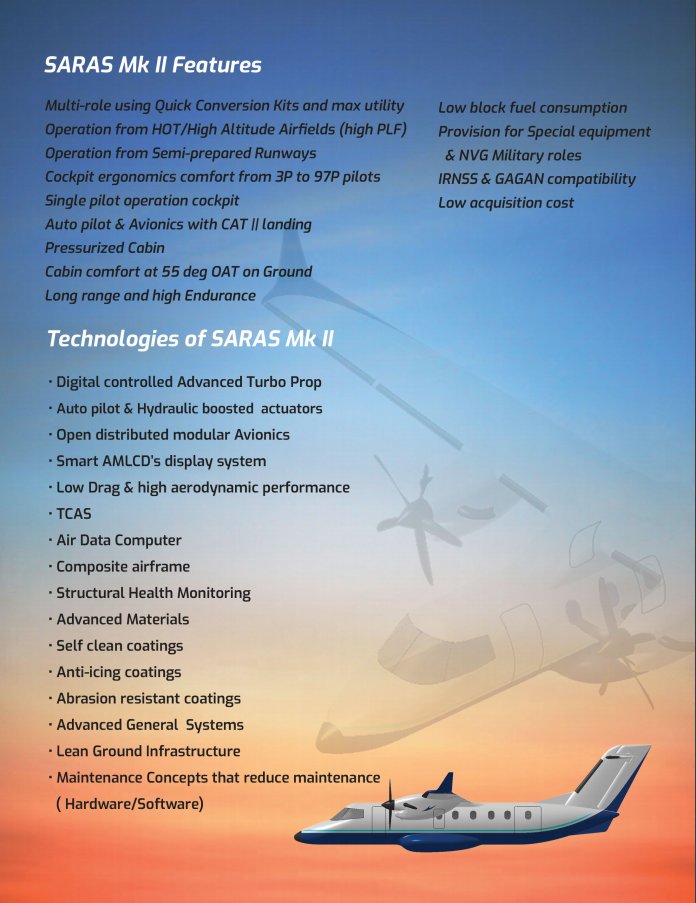

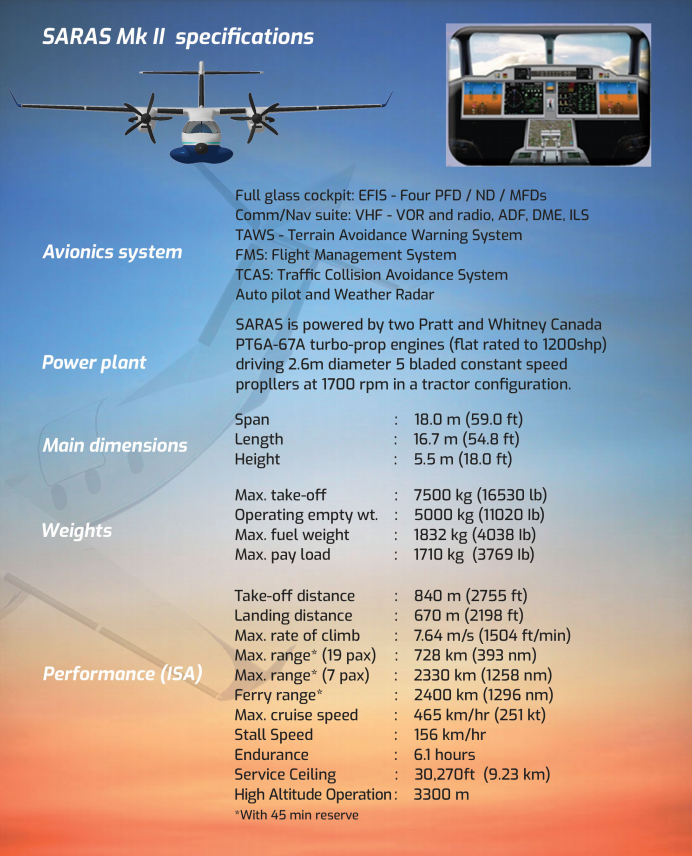

#SarasMK2 Brochure. Its looks like its embellished with all the bells and whistles. Its better than Do228 in practically every sense.

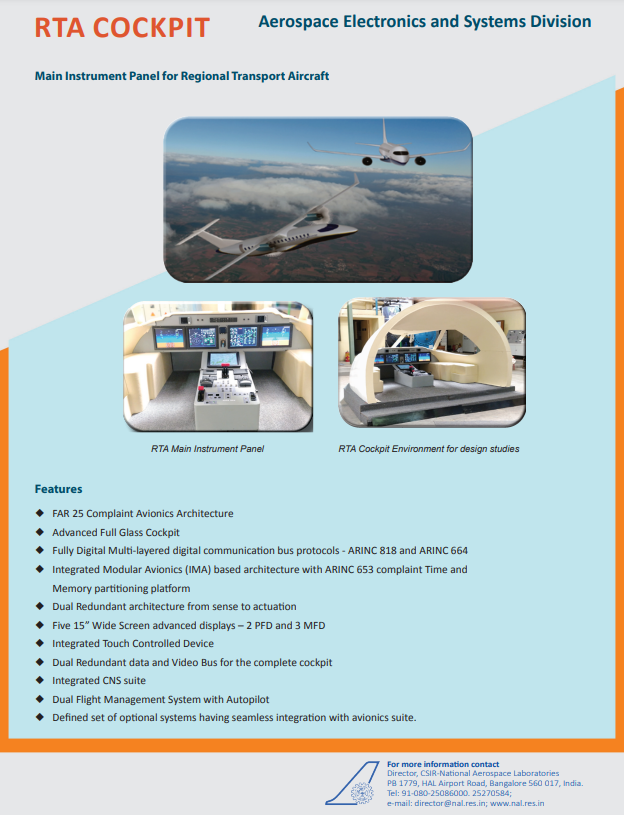

Glass cockpit meat for RTA70. Not sure if this mock up will be displayed in the #AeroIndia2021 or not.

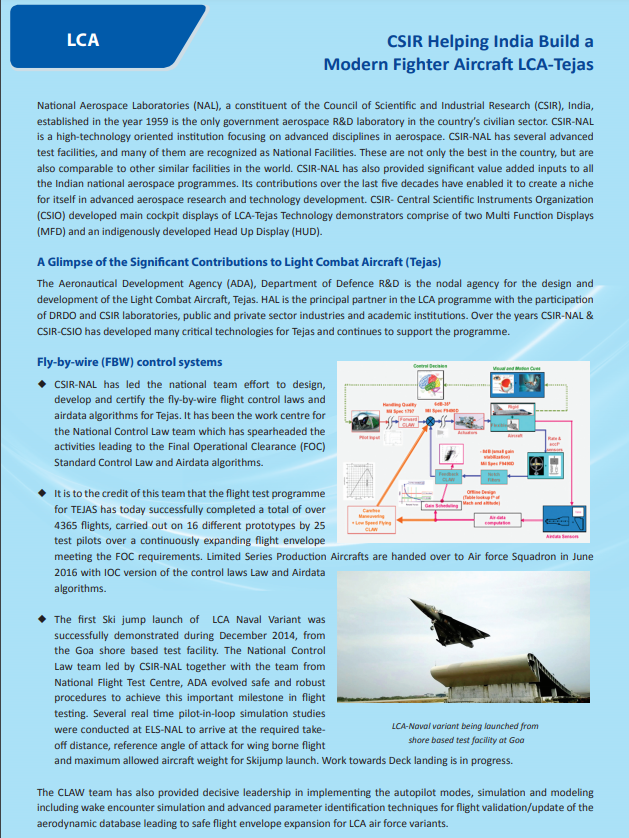

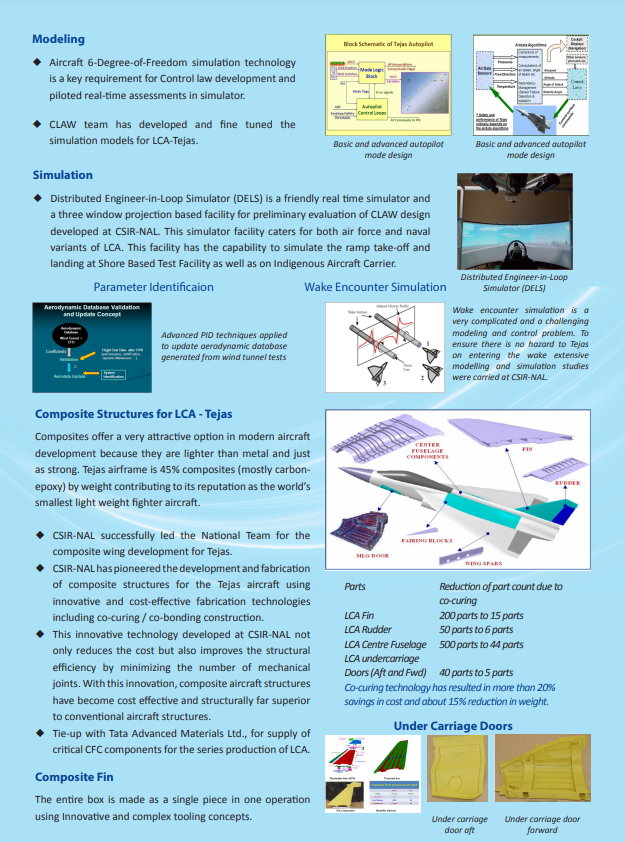

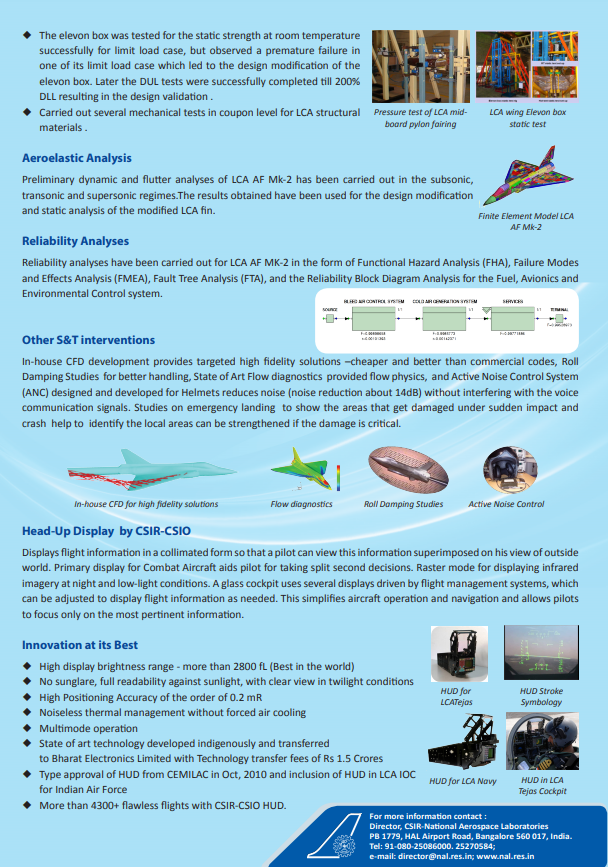

These 4 pages summarize NAL's contribution to the #LCA program. So much stuff in there. All those who wonder what was happening in LCA program for 30yrs, should study this in detail. And keep in mind that this is only one lab out of more than 100 work centers involved in LCA. All

the basic technology, design, development, testing, validation and manufacturing developed here over 3 decades form the bedrock on which the Indian Aviation sector is standing today. We had literally none of this existing in India in 80s. Everything is developed from scratch in

meagre funding and against all the odds. This is why LCA has taken a while. Now that we have all this know-how and most importantly the know-why at hand, we are pretty confident that the next iterations and programs can be completed in time bound manner without much technological

risk. Lets take the example of FBW FCS. The CLAW team developed the mathematical framework for the FCS of an unstable Fighter from scratch. They developed the 6-DoF simulation capabilities, Eng-in-loop, Pilot-in-loop, HW-in-loop and so on capabilities and facilities. The methods

and the best practices are well established and well validated by now. For Tejas Mk2, TEDBF, AMCA, all this is going to be used practically as it is with only incremental changes. Which means those programs do not have the lead time of 10-15yrs that is needed to develop all these

capabilities. What more, given the validation and finetuning from LCA Mk1 flight testing, all these tools and design best practices are matured enough to predict/create new systems for MWF or AMCA which are far more accurate and close to the reality in first iteration itself.

This is going to cut down the Design & Development time for the FCS and on the flight testing and certification.

For AMCA you dont anymore have to struggle to develop basic composite tech, only work on how to make the composites more stealthy by c-nanotube infusion or some other

For AMCA you dont anymore have to struggle to develop basic composite tech, only work on how to make the composites more stealthy by c-nanotube infusion or some other

means (which they have been working on in past decade). NAL already has developed technology right from Carbon fibre production to very advanced composite component manufacturing. The base is already there now, unlike in the 80s and 90s.

Now apply this for every single technology

Now apply this for every single technology

and component that is going in the future Fighters. Then you will understand where does the confidence that ADA displays today on timelines come from and why we can afford to aim for rather aggressive timelines for TEDBF, AMCA etc. Today we are more limited by funding than tech.

A poster on NAL's composite fibre making technology development. The technology was transferred to Kemrock which is now acquired by Reliance, AFAIK. Hope Reliance can scale is up to eliminate our import dependence. With their petrochemical and textile background, they are in a

unique position to aim for a global role in Carbon fibre production. And there is no dearth of capital as well. ;)

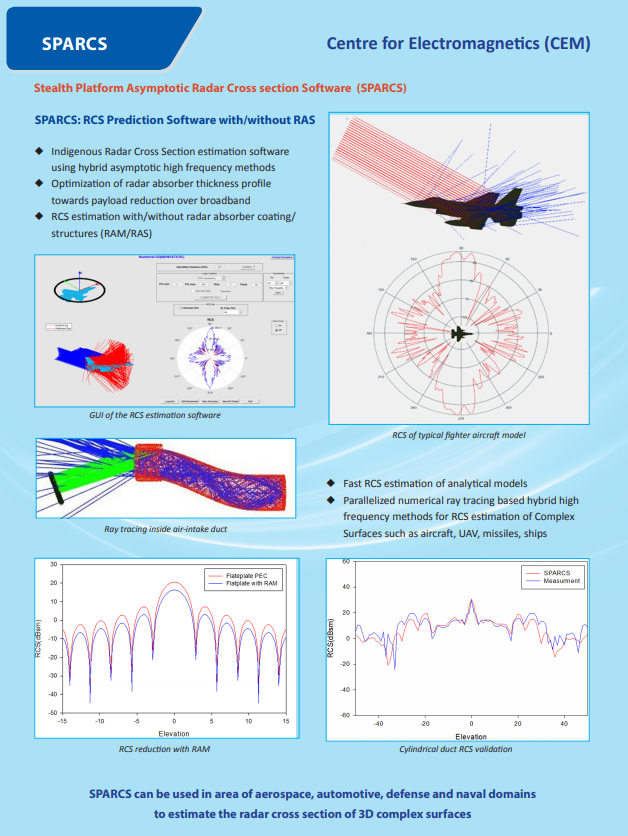

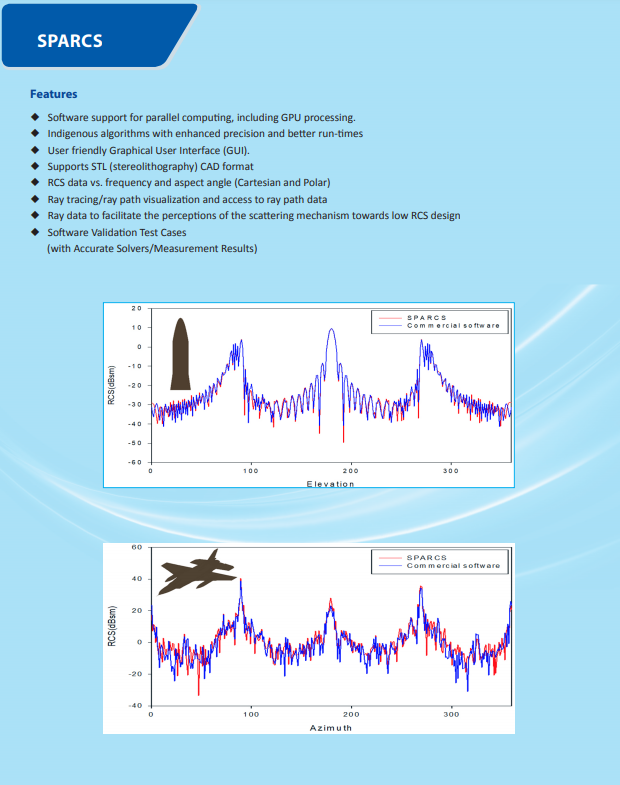

Our own desi RCS prediction SW - SPARCS - Stealth Platform Asymptotic Radar Cross Section Software, developed by NAL. We can see some examples simulated in the SW - F16, serpentine air intake and terminal stage of an ICBM.

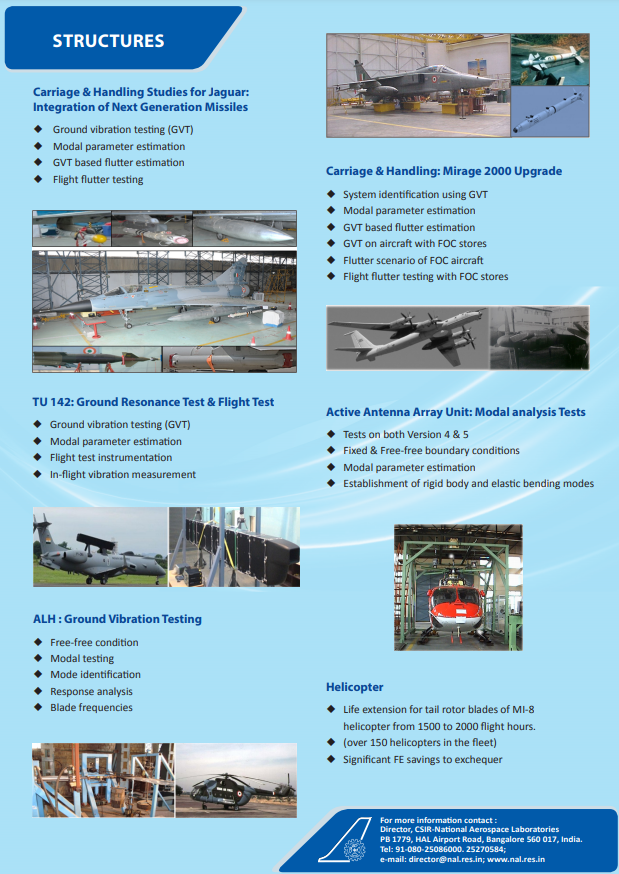

NAL's Structural test facilities and capabilities - Structural strength, fatigue life, ground vibration, in-flight vibration. mode identification, flutter, structural life extension and so on. NAL is the key agency in these capabilities.

This is interesting. NAL has developed a control carry case for local repair of composite panels of airframe or similar application.

A cool marketing video by Astra Microwave. They are supplying to practically every desi Radar/EW program.

A couple of AI ago, they were displaying RF seekers for BrahMos & AAM. Now I see a gimbled AESA seeker for missile under dev. @Firezstarter1

A couple of AI ago, they were displaying RF seekers for BrahMos & AAM. Now I see a gimbled AESA seeker for missile under dev. @Firezstarter1

@writetake has come up with this great series #InspiringADA. A brief but crisp update on ADA programs. Its good to see ADA folks talking in terms of program mile stones of PDR, CDR and so on. Its makes things crystal clear. I wish ADA (and indeed the entire @DRDO_India) could

maintains webpages on their sites which displays updated status of each of the publicly known programs in terms of the Program milestones like CR, CDR, PDR, FAI to precisely let the Citizens know about the status and expected timelines.

Here is the link to @writetake's #InspiringADA 4-part series thread. Do watch it. AKM's efforts to bring forth the "unsung heroes" in the limelight is commendable. Seeing the Team LCA even more enthusiastic than us jingo gives immense satisfaction. https://twitter.com/writetake/status/1351568582224723968?s=20

And here is my rather long thread containing comments and highlighting the key points in the update. https://twitter.com/nileshjrane/status/1351604444522110976?s=20

The complete #InspiringADA Series

Part-1A | https://bit.ly/3pc8nZK

Part-1B | https://bit.ly/3qBJZ45

Part-1C | https://bit.ly/3bYsXsG

Part-1D | https://bit.ly/2LUuXHV

Part-02 | https://bit.ly/2MiLxkL / AMCA

Part-03 | https://bit.ly/36abV7b / TEDBF

Part-1A | https://bit.ly/3pc8nZK

Part-1B | https://bit.ly/3qBJZ45

Part-1C | https://bit.ly/3bYsXsG

Part-1D | https://bit.ly/2LUuXHV

Part-02 | https://bit.ly/2MiLxkL / AMCA

Part-03 | https://bit.ly/36abV7b / TEDBF

Part-04 | https://bit.ly/3a4Hi4n / Young Scientists Forum (R-Day Special)

Part-05 | https://bit.ly/3qYu5Rk / #LCAAFMk2

Part-06 | https://bit.ly/3a8ZtGf / Virtual Reality

Part-07 | | NLCA Mk1

Part-05 | https://bit.ly/3qYu5Rk / #LCAAFMk2

Part-06 | https://bit.ly/3a8ZtGf / Virtual Reality

Part-07 | | NLCA Mk1

While ADA creates #TEDBF, NLCA MK1 will continue to provide invaluable flight testing experience and technology development for which will reduce the timelines for TEDBF significantly. For example, NLCA Mk1 already has certified all 350+ LRUs for landing

shock conditions (which is something which MiG29K was struggling with for quite a while even after induction). Any new/updated LRUs meant for TEDBF could be deck certified well in advance on NLCA Mk1 itself, cutting down the certification time for the same on TEDBF itself. Apart

from this NLCA, after proving the design capabilities, will now continue flight testing of the off-design conditions. The data coming from these tests will help optimize the TEDBF LG and Arrester hook design in the first iteration itself. Everything needed fr TEDBF could possibly

be tested on NLCA Mk1 a priori ahead of time. In addition, NLCA will continue the technology development. For example a immediate target is connecting the GE engine FADEC to the FCS so that the engine thrust could be controlled by the FCS directly without pilot inputs. Those who

Read on Twitter

Read on Twitter