Its that fun time of year where we get to see everything wrong with US vehicles (and other kit, but I’m a land warfare kind of man) – the Director, Operational Test & Evaluation reports are out!

Below a selection of some of the more noteworthy comments amongst vehicle programmes

Below a selection of some of the more noteworthy comments amongst vehicle programmes

A note that DOT&E reports are absolutely brilliant. Candid & transparent, unparalleled in any other country & should be held up as an outstanding effort that should be emulated. They reveal issues & plans to resolve them, & give insight into challenges of developing complex kit

(A) Infantry Squad Vehicle. This is a light strike type vehicle to provide much higher mobility and speed to traditionally dismounted infantry in the IBCT formations, particularly Airborne and air assault doing offset entry

Shockingly (sarcasm), the testing showed being in a vehicle can make you faster and less predictable in movement than on foot during rapid offensive operations, and radically expands an IBCT area of operations

Problems:

(1) ISV cant carry the 9-soldier + gear + 72hrs supplies payload due to lack of internal space, requiring additional ISVs as logistics carriers.

(2) ISV did not specify a mounted comms requirement, personal/manpack radios are insufficient over distances ISV operates

(1) ISV cant carry the 9-soldier + gear + 72hrs supplies payload due to lack of internal space, requiring additional ISVs as logistics carriers.

(2) ISV did not specify a mounted comms requirement, personal/manpack radios are insufficient over distances ISV operates

Comms between squad leader, soldiers, and platoon leader was intermittent and not reliable.

(3) The chosen solution, General Motors ISV (based on Chevrolet Colorado) was most reliable, but still demonstrated only 585 miles between operational mission failure vs 1,200 requirement

(3) The chosen solution, General Motors ISV (based on Chevrolet Colorado) was most reliable, but still demonstrated only 585 miles between operational mission failure vs 1,200 requirement

(4) “All vendors’ ISVs [were] cramped and soldiers cannot reach, stow, and secure equipment as needed, degrading and slowing mission operations soldiers could not readily access items without stopping the movement, dismounting, and removing rucksacks from the vehicle.”

The lack of underbody or ballistic protection raises concerns, and vehicles will have to avoid threats and take concealed routes, slowing them and inherently undoing much of their speed and mobility benefits

TDLR: Essentially it’s a small, light and unarmoured vehicle, and they're finding that this means its small, light and unarmoured. Not much you can do about that, the reliability is an issue and a concern given its based on a very mature commercial platform

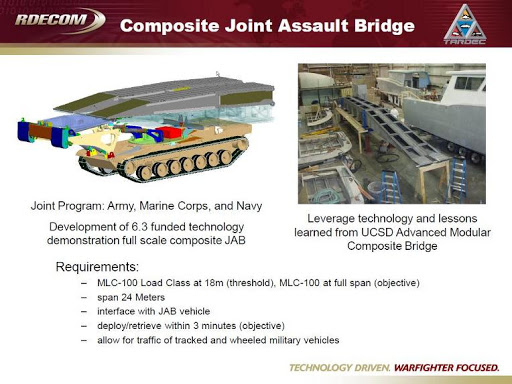

(B) Joint Assault Bridge (JAB). The ABCTs AVLB capability, simple as that. Replaces M60 and M1074. TTP development testing showed it can lay a bridge and cross a ditch, which is rather good given its an AVLB, so the basic work fine.

The main problem is significant reliability issues to the extent that Full Rate Production (FRP) is deferred. Fixes will be made, then another round of IOT&E testing. Issues are not explicit, but it mentions bridge launch mech and hydraulic power unit being problems

The live fire testing in 2018 showed concerns around protection, though unlcear if direct, indirect or underbody threats that are the issue. These are stated to be satisfactorily resolved by the new Automatic Fire Extinguishing System updates, so probably underbody or DF.

TLDR: Reliability an issue, but not clear exactly what and why. Hopefully just teething problems with a new system. Good to see the broader protection related concerns are resolved.

(C) Armored Multi Purpose Vehicle (AMPV). The replacement for M113, using new Bradley based hulls in General Purpose (GP), Mission Command (CD), Medical Evac (ME), Medical Treatment (MT) and Mortar Carrier (MC) variants.

Existing delays with production were confounded by COVID, and the programme is around 6-8mths behind now. 24 key issues were identified in Limited User Testing (LUT) and 21 are corrected. Five remain issues that are not expected to be resolved by the next testing round

(1) Hatch and roof leak, fixes to date have not resolved this. (2) the mortar carrier hatch is difficult to open. The next three have no known solution at this time. (3) Footrest in ME interferes with entering and exiting vehicle

(4) CD internal configuration prevents flexible mission rerolling, (5) MT seating does not allow effective treatment of casualties in transit (this feels a rather signfiicant issue)

Vulnerabilities during live fire testing are being worked on but have not yet been proven to have been resolved with further live fire test, though changes have been actioned and all looks good in that regard.

TLDR: Some gripes, nothing critical unless next round of live fire shows vulnerabilities endure. Internal configuration issues in some variants leave suboptimal solutions, but dont appear disastrous, especially when considering broader capability uplift from ancient M113s to AMPV

(D) M109 PIM. Comprehensive upgrade to M109A7 SPH and M992A3 CAT primarily around mobility & electrics. Two armour standards are being fitted, T1 is baseline, T2 is an add-on kit for combat operations. An additional underbody kit has been developed but is not being taken forward

Overall, the vehicles are operationally effective and are significant improvements over old versions, the CAT in particular is well ahead of reliability target.

Modifications to the gun appear to have resolved concerns in the last report around breech reliability failures at high charge, meanwhile an all new sliding breech is being developed for a wholesale replacement.

“The crew compartment Automatic Fire Extinguisher System (AFES) in the SPH was designed to protect a small, localized area and is deficient in providing adequate fire survivability.” To be resolved by a new AFES design.

Modifications are being made to better protect against underbody blast – floor mat retention, vertical ammunition covers/retainers, reinforced brackets and fixtures throughout vehicle.

TLDR: Its all looking fairly clear for PIM now after some dire feedback in prior years around those breech failures. Underbody survivability is a very tough game in a vehicle not designed for it, so those issues are what they are and are being dealt with well

(E) Stryker. Covered as a single update, the report primarily covers the ATGM MITAS variant ECP and the CROWS-J weapon station ECP. The Stryker MGS was in the reports last year, guess theyre not in any active test over the past 12 months

The ATGM MITAS (Modified Improved Target Acquisition System) ECP is a general refresh of the ATGM variant – new camera, FCS, launcher hardware and more (main items list pictured)

The CROWS-J ECP is trying to flush out and fix issues with the CROWS-J which was fielded as an urgent requirement and consequently was not run through full testing and resolution of technical issues.

Testing had to be reduced due to poor reliability, noting especially poor software reliability resulting in much slowed Javelin engagement times and problems with the FLIR sight that led to target ID issues

A cooperative and an adversarial vulnerability and penetration assessment (CVPA) will be carried out in June after systems deployed to Europe experienced degraded performance following exploitation of ‘cyber’ vulnerabilities

A non-specific issue exists with CROWS-J “against kinetic threats identified a crew vulnerability related to the vehicle’s hatches” which is to be investigated and resolved in a classified setting

TLDR: Some fairly normal bugs in early development, though the nature of the programme means these are being discovered in deployed vehicles, which isn’t ideal. CROWS-J not an excessively complex retrofit and a proven base RWS< so its disappointing to see major issues noted

(F) IM-SHORAD. An interim (as was Stryker don’t forget) capability to provide SHORAD vs fixed, rotary & Group-3 (medium) UAS at ratio of one IM-SHORAD battery per brigade. Mounts Stinger, Hellfire, 30 mm cannon and 7.62 mm MG on ‘RiWP’ unmanned turret, on a Stryker DVH A1 vehicle

The vehicles acquired so far have been prototypes and not speaking to a formal directed requirement. This means testing has been very limited and even then, not threat representative. Being prototypes, they need significant retrofitting before they can be fielded

In particular, the operational assessments were “not executed in an operationally representative electromagnetic spectrum contested environment with threat-representative electronic warfare systems attacking the system.”

“The IM-SHORAD fire units used during the OA were prototypes that will require retrofitting prior to fielding. The Army has not yet funded future operational testing with production-representative vehicles”

“Hellfire Longbow missile lethality assessment versus fixed- and rotary-wing targets is reliant on accurate air target signature models, which are currently of low fidelity and need to be adequately verified, validated, and accredited.”

TLDR: These are very nascent systems and have a mountain of test and development before they’re actually ready, expect many more issues to arise and be worked through before its ready to field properly. A nonetheless high potential and much needed SHORAD system

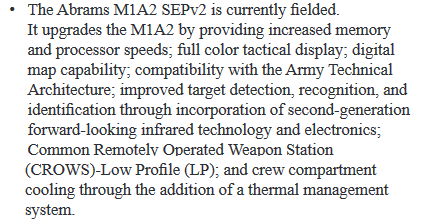

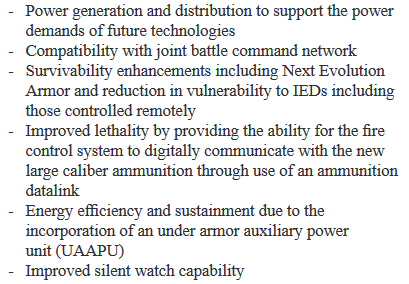

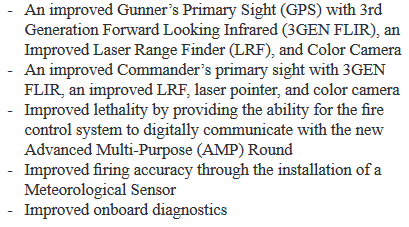

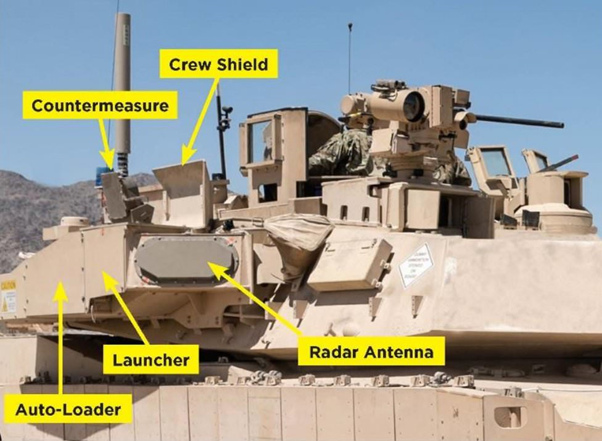

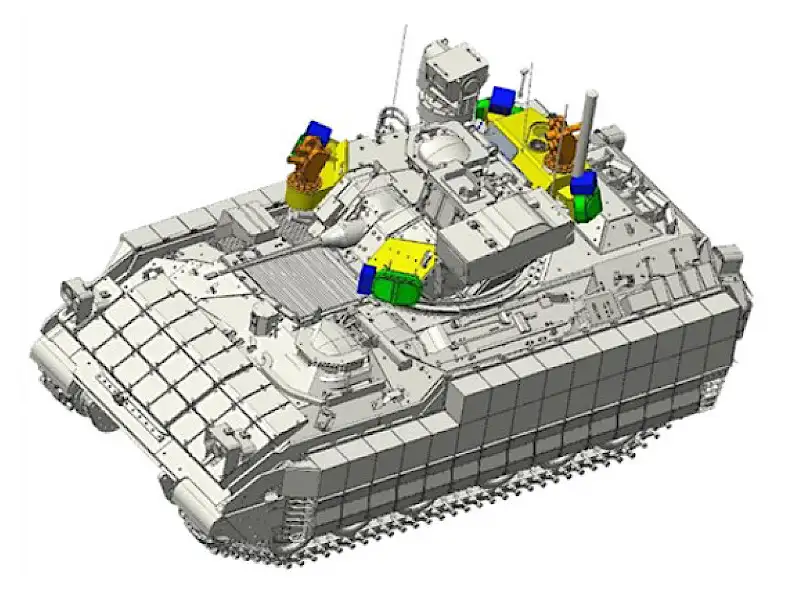

(G) M1A2 SEP. Covers the SEP upgrades and includes the installation of Trophy. The SEP initiates are excellent spiral development of the M1 platform, keeping it relevant, and sustaining the industrial base for decades. Latest version in testing is SEPv3, with SEPv4 due Q1 FY25

SEPv2 is fielded, but has been augmented with the Israeli Trophy APS, which is also being looked at for the UKs Challenger 2, as an aside, and will go on SEPv3 too. Upgrades are listed above.

SEPv3 started fielding in Q4 FY20 and is iterative to v2, with the above elements. The UAAPU in particular is neat, giving a 78% reduction in fuel usage versus main engine, and 62% acoustic detectability range reduction

Trophy adds c. 5,000 lbs (or 2,250 kg to the rest of the planet) to the weight of the vehicle. The Army intends to install Trophy on SEPv2 and SEPv3 tanks and field 4 Armor Brigade sets to prepositioned stocks domestically and outside of the US

Broadly, SEPv2 is very capable at doing what it needs to, meets requirements and eliminates capability gaps as intended. It exceeds reliability requirements – 441 miles between failures versus 320 requirement.

SEPv3 raises issues of reaching practical limits. Weight increases now limit transportability – too heavy for recovery vehs, tactical bridges & HETs. Crews struggled with GFE equipment (unspecified). CRWS-LP sight swashed out on ops, though latter could not be replicated in test

The live fire test for SEPv3 with Trophy does not include relevant threats as identified by the ‘intelligence community’. This needs resolution before the testing takes place to ensure it meets the needs of future threat landscape.

Survivability findings are classified, but the recommendation to “Consider the findings of the SEPv3 evaluation reports to enhance the survivability of future upgrade” suggests there are vulnerabilities to resolve

TLDR: ECP and resultant SEP standards have always been fantastic from capability & industry perspectives. SEPv2/3/4 all very worthwhile upgrades. Key issues seem to be secondary effects – SEPV3 is too heavy to deploy and support. $$ required to go upgrade all that kit as a result

(H) Amphibious Combat Vehicle (ACV). Is the result of the decades long failure to get an AAV7 replacement. The ‘true’ ACV, formerly EFV, has been punted to the 2035+ timeframe and meanwhile the USMC procured the 8x8 amphibious ACV, based on SUPERAV.

ACV fundamentally meets its requirements and can complete notional missions effectively alongside JLTV and LAV, it performs objectively and anecdotally better than legacy vehicles across all mission profiles including a 12 nm ocean swim and subsequent beach crossing.

There are classified and thus not detailed survivability vulnerabilities that require action, purportedly around kinetic attack, which may be resultant of the rather unique design of SUPERAVs hull which armours the vehicle rather differently to most. Pure speculation though

ACV operations in sand saw regular tyre failures, and the lack of hydraulic jacks or other means to lift the vehicle led to 2hr or more tyre change delays. A number of failures related to incorrect monitoring of the CTIS, which is more critical in very soft terrain and sand

Recovery is challenging due to the ACVs size and weight and requires multiple LVSR to carry out, which may require increasing the number of LVSR in formations

At full compliment of 3 crew and 13 infantry plus kit for 48hrs combat operations the vehicle is cramped (shockingly!) and ingress/egress a challenge. Seats do not contour to armour and are uncomfortable for prolonged use.

Mean time between operational failure is below requirement of 69 hours (which feels very low to me?) at 39 hours. The largest number of failures were the RWS, which is GFE. Other significant causes were suspension, hatch and ramp sensors, and unspecified switches.

TLDR: Classified survivability issues exist against direct fire kinetic threats that require resolution. Reliability remains an issue, and some niggles endure (wheel changing and comfort for pax in combat body armour)

There is a bunch more information in the full reports and a LOT more programmes across all services at the full website here: http://shorturl.at/aeoAC

#miltwitter #tanktwitter #DOTEReports #AFVDesign

#miltwitter #tanktwitter #DOTEReports #AFVDesign

I failed to copy the Bradley ECP section in. Bradley ECP, much like M1A2 ECP, is sustaining the Bradley fleet and industrial base with constant tweaks and enhancements as it rolls well beyond the point it was to be replaced.

ECP Phase I looked at suspensio nand track upgrades to restore ground clearance and reliability as weight has increased thru life. ECP Phase II is looking at electrics and power train to restore mobility and power existing and future upgrades

Phase I and II results in the M2A3 and M2 ODS-SA being converted to M2A4, and M7A3 being converted to M7A4. Once complete, there should be four brigade sets including one for the EDI.

Bradley was to be integrating Iron Fist APS, but intiial testing had high dud rate and failure to engage, which was identified to be due to insufficient electrical power. The A4 upgrade is therefore being acelerated as a prerequisite to the APS integration being possible

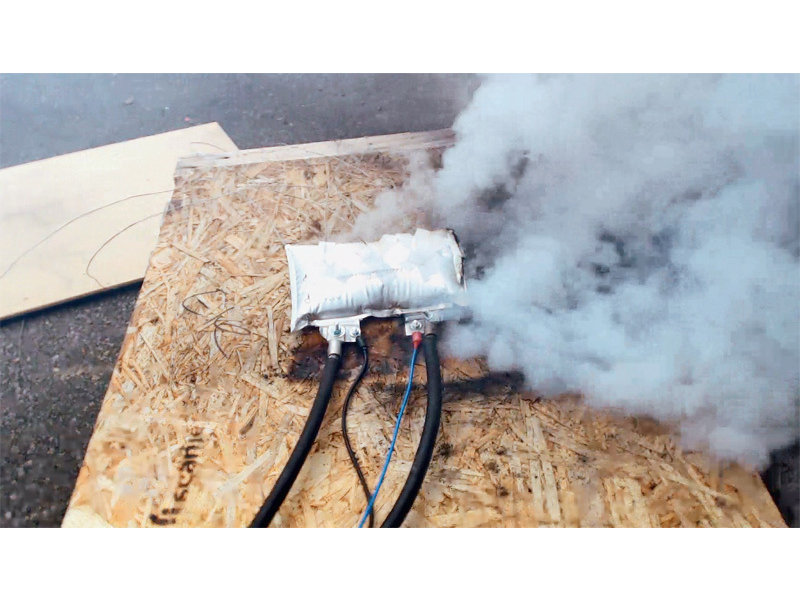

An M2A4 platoon (4x M2A4) + Coy Fire Support Element (1x M7A4) and Coy HQ (1x M2A4) carried out a cooperative vulnerability and penetration assessment in 2020. All six vehicles' turret batteries oiverheated & vented gas into turret and crew compartments.

Follow on gunnery trials are on pause while battery issue resolved. Its not a major tecnical challenge as such, but obviously a huge danger to crews and the A4 is not fit for purpose until resolved. The Army anticipates a delayed decision date as a result.

Read on Twitter

Read on Twitter

![(4) “All vendors’ ISVs [were] cramped and soldiers cannot reach, stow, and secure equipment as needed, degrading and slowing mission operations soldiers could not readily access items without stopping the movement, dismounting, and removing rucksacks from the vehicle.” (4) “All vendors’ ISVs [were] cramped and soldiers cannot reach, stow, and secure equipment as needed, degrading and slowing mission operations soldiers could not readily access items without stopping the movement, dismounting, and removing rucksacks from the vehicle.”](https://pbs.twimg.com/media/ErusPxvXAAMRn7_.png)