#plamoSE

So, with the new year and all that I though we should take a look ahead and try to catch a glimpse of the modeling future!

I think we are rapidly approaching the point where 3D printing will be able to replace resin casting.

Here’s why (thread):

(1/18)

So, with the new year and all that I though we should take a look ahead and try to catch a glimpse of the modeling future!

I think we are rapidly approaching the point where 3D printing will be able to replace resin casting.

Here’s why (thread):

(1/18)

A good resin printer is now available for under €300. Splash out €800 and you will get the top of the line.

I have recently had the opportunity to see for myself what one of the best ones are capable of and thought I would share that with you all.

(2/18)

I have recently had the opportunity to see for myself what one of the best ones are capable of and thought I would share that with you all.

(2/18)

How it began: my friend @SweShaggy has acquired an @anycubic3dprint Photon Mono X, which is a 4k resolution, monochromatic LED-screen liquid resin printer with a fairly large print area. Resolution is good because it means finer detail!

Link: https://www.anycubic.com/collections/anycubic-photon-3d-printers/products/photon-mono-x-resin-printer

(3/18)

Link: https://www.anycubic.com/collections/anycubic-photon-3d-printers/products/photon-mono-x-resin-printer

(3/18)

I mentioned needing a second Scammell engine for a project (pictured) and he generously offered to print me one - if I could find a CAD-drawing of it!

I couldn’t find one though, so I thought I could at least *try* making one myself.

(4/18)

I couldn’t find one though, so I thought I could at least *try* making one myself.

(4/18)

By sheer luck I stumbled upon @tinkercad and immediately fell in love.  It’s a free, browser based CAD tool with a very intuitive interface.

It’s a free, browser based CAD tool with a very intuitive interface.

I tinkered (heh) with Bryce 3D as a kid and TinkerCAD reminded me a lot of that.

(5/18)

It’s a free, browser based CAD tool with a very intuitive interface.

It’s a free, browser based CAD tool with a very intuitive interface.I tinkered (heh) with Bryce 3D as a kid and TinkerCAD reminded me a lot of that.

(5/18)

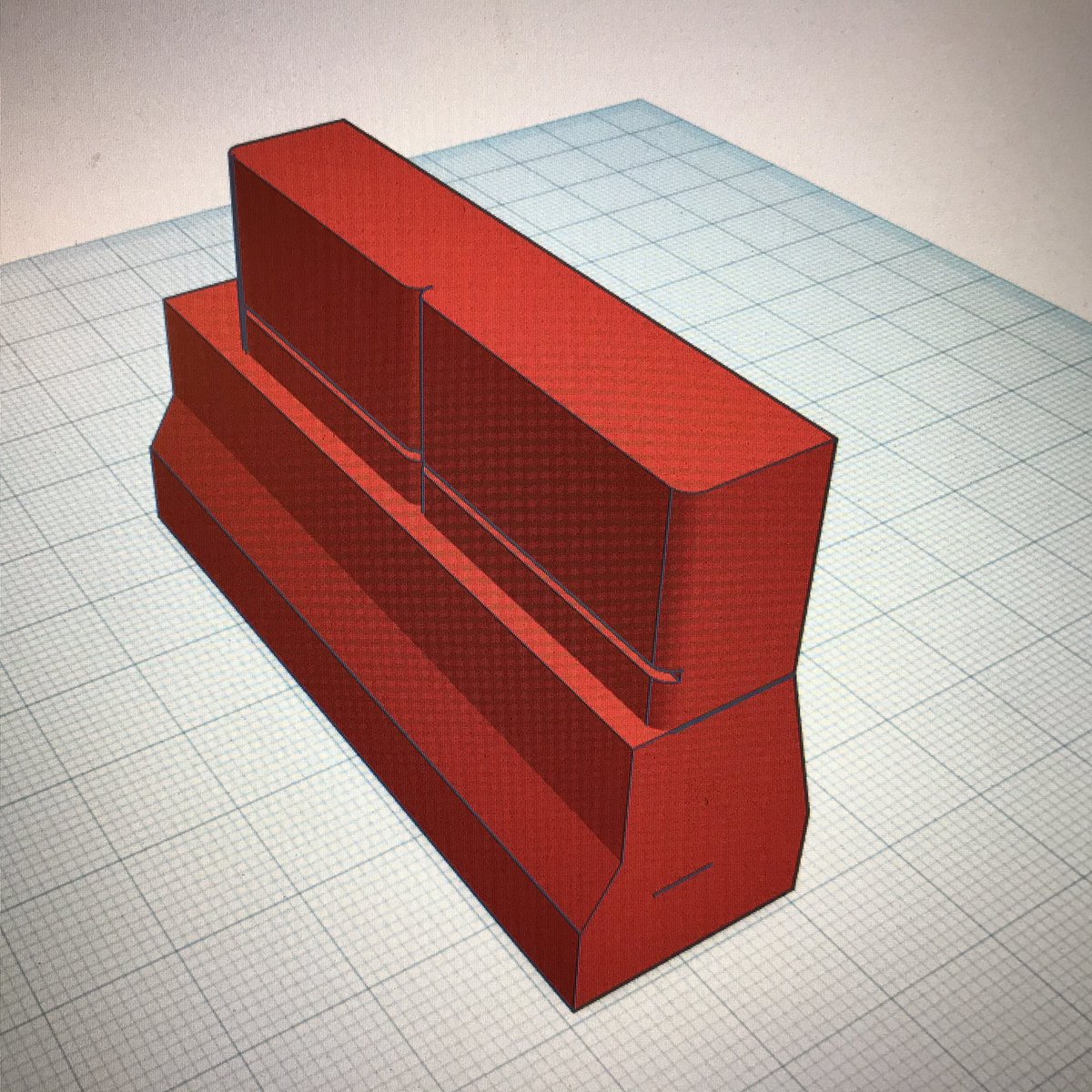

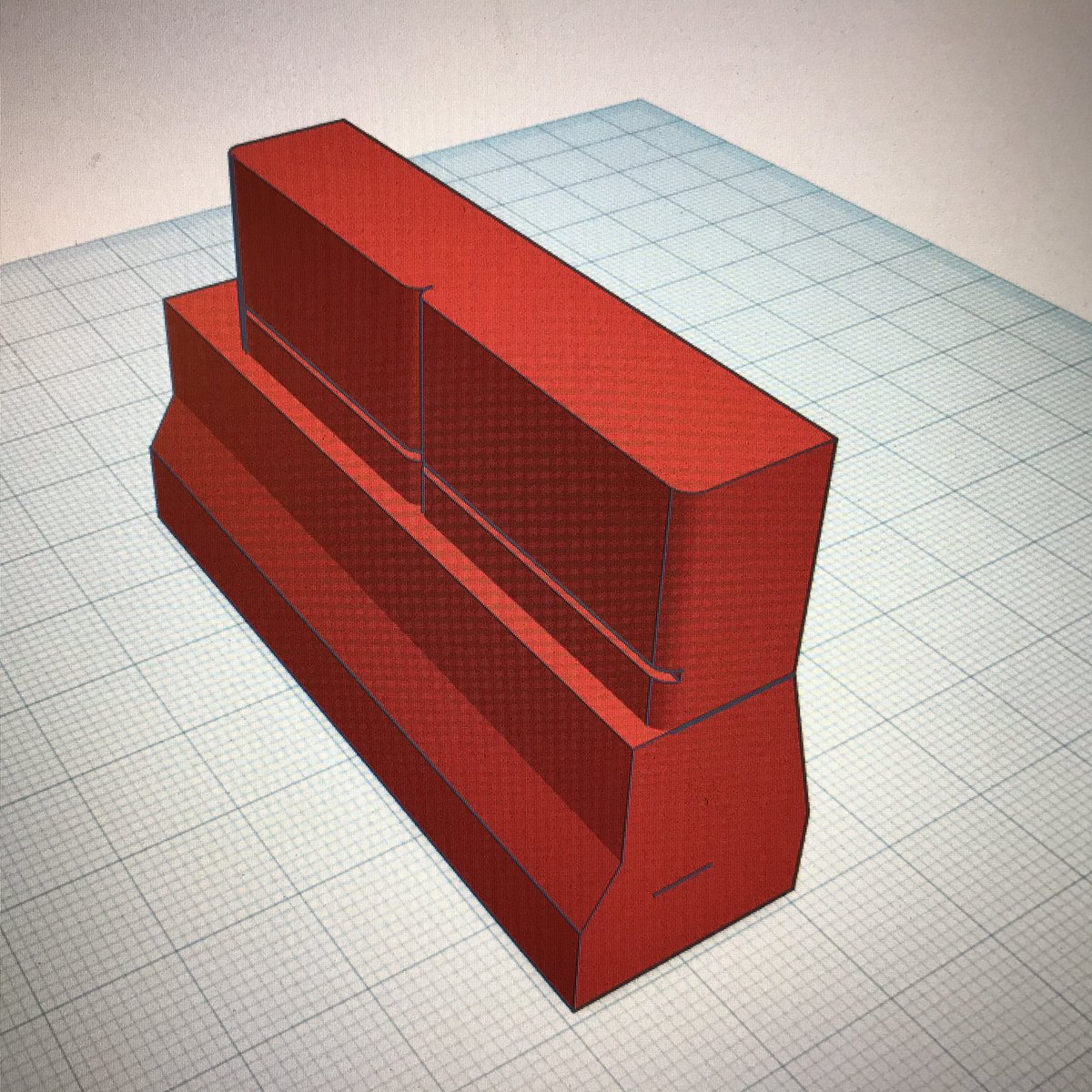

You basically have a bunch of primitive shapes (cubes, cylinders, spheres), you can create them, re-size them, group them and - importantly - make them negative and use them to cut other shapes.

It’s the MS Paint of CAD and I love it.

(6/18)

It’s the MS Paint of CAD and I love it.

(6/18)

So, I set about creating an extra engine for my Scammell in 1:35th scale by looking at pictures of the real thing and looking at the one I got when I bought Thunder Models kit.

Here’s how that went - I didn’t count but I guess this is about 8-10 hours of work.

(7/18)

Here’s how that went - I didn’t count but I guess this is about 8-10 hours of work.

(7/18)

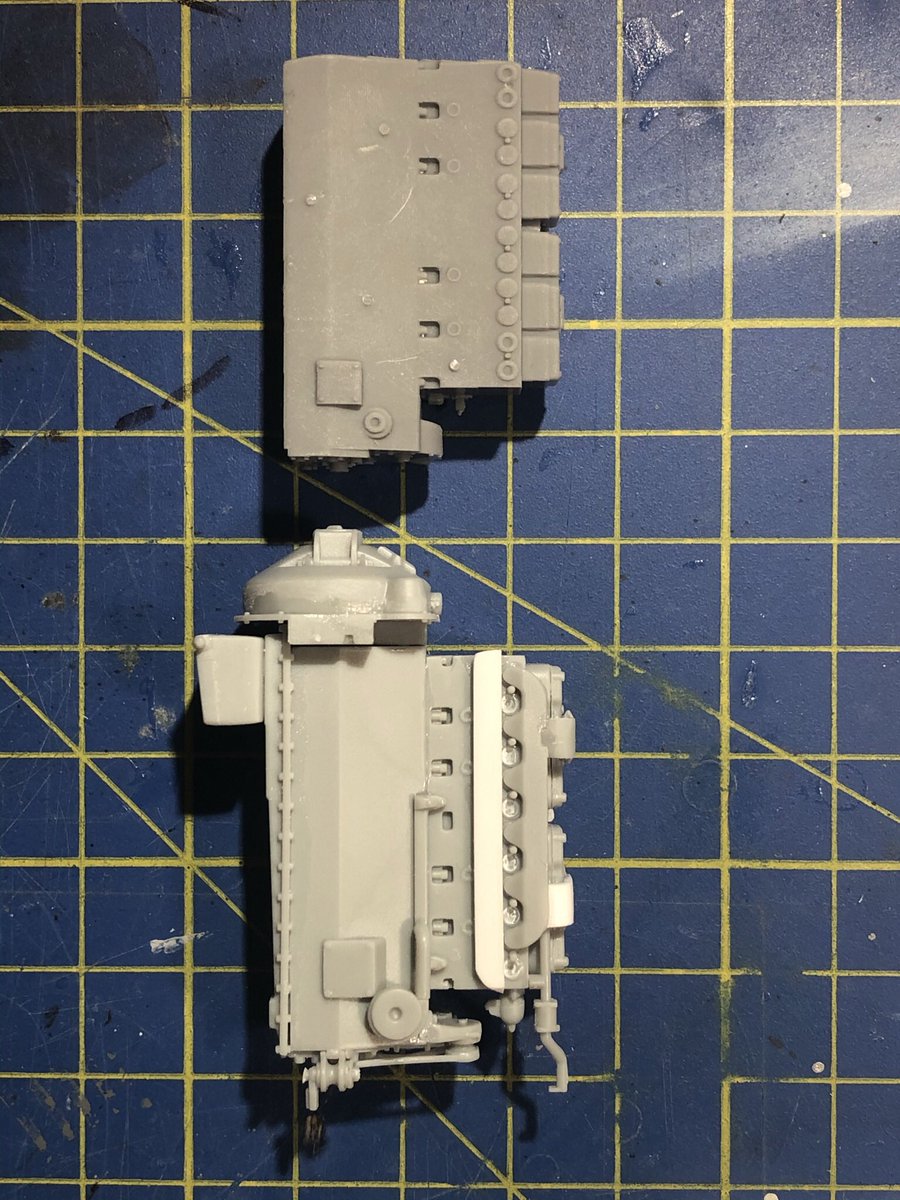

..And this is what I got in the mail today.

Printed by @SweShaggy on an Anycubic Photon Mono X using the @AmeraLabs AMD-3 Resin. Just look at the detail!!

(8/18)

Printed by @SweShaggy on an Anycubic Photon Mono X using the @AmeraLabs AMD-3 Resin. Just look at the detail!!

(8/18)

Now, let’s compare the 3D printed one (dark grey) with the polystyrene injection molded one (light grey) that I got in the box from Thunder Models.

I would argue the 3D-print is actually a lot crisper than the molded one.

(9/18)

I would argue the 3D-print is actually a lot crisper than the molded one.

(9/18)

Now, in the near future I don’t see injection molding going away, I’m no expert but I’d guess economics of large scale production are still tipped towards molding.

Resin casting, on the other hand - short production runs, high level of detail, rare subjects - PERFECT!

(10/18)

Resin casting, on the other hand - short production runs, high level of detail, rare subjects - PERFECT!

(10/18)

I’m mainly modeling Soviet 1960-1990 commercial vehicles (trucks and tractors), that’s a fairly niche topic and I’m often chasing down rare and expensive resin conversion sets.

These typically cost €50 - €200, ie. as much as or often more than the base kit itself.

(11/18)

These typically cost €50 - €200, ie. as much as or often more than the base kit itself.

(11/18)

Given that I now - thanks to @SweShaggy - had access to a 3D-printer, I wanted to see if I could make a conversion set myself.

I picked this topic, an ultra-rare (two prototypes made, none remain) Maz 7310 timber crane.

(12/18)

I picked this topic, an ultra-rare (two prototypes made, none remain) Maz 7310 timber crane.

(12/18)

The timber bed itself is easy to scratch build, but the Fiskars 120S crane is a different matter.

It seemed the perfect test subject, so I started tinkering... Did I mention I @tinkercad?

@tinkercad?

(13/18)

It seemed the perfect test subject, so I started tinkering... Did I mention I

@tinkercad?

@tinkercad?(13/18)

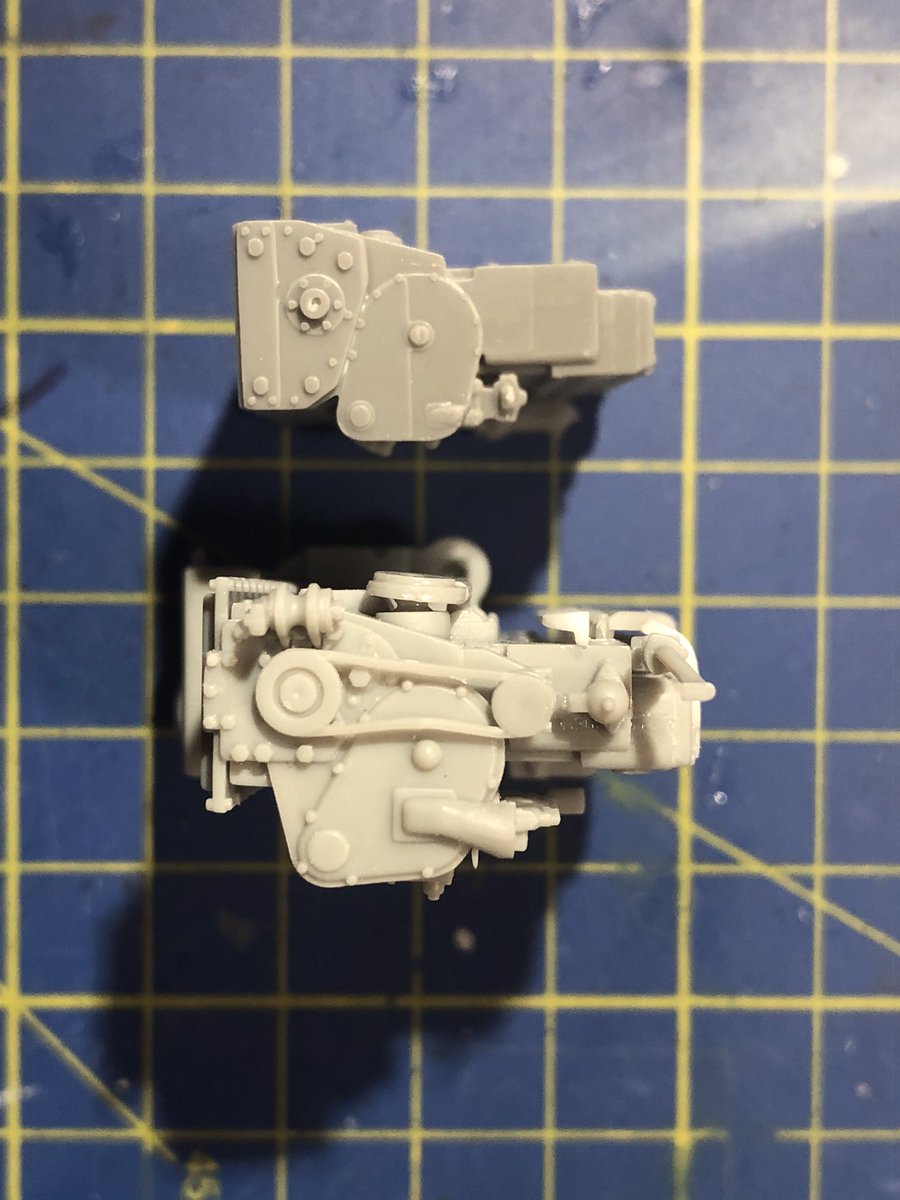

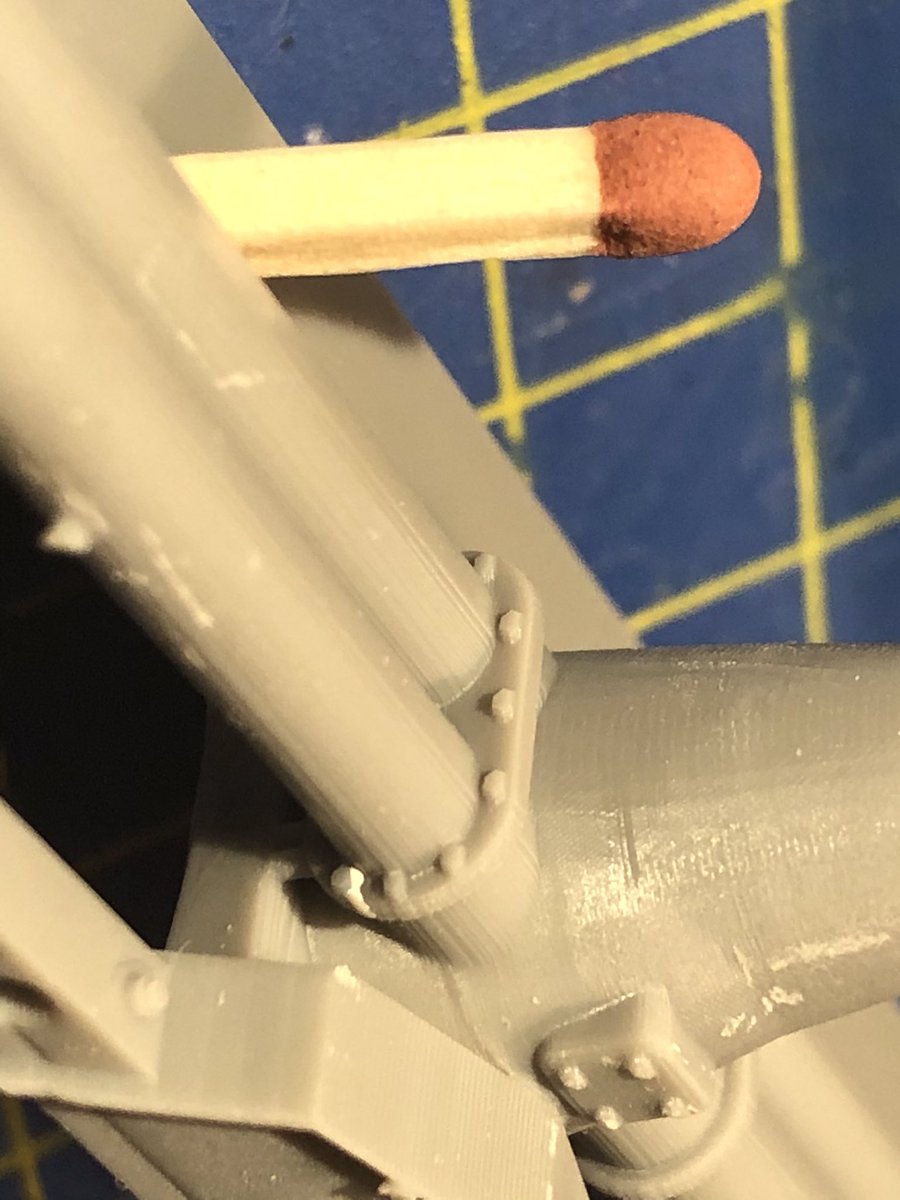

And here’s the printed result. I will use brass rod, tubes and lead wire to make the actuators, connectors and hydraulics so these are just the main components but still - I’m amazed at how this turned out.

Those bolts in the last pic are 0.3 mm wide!

(14/18)

Those bolts in the last pic are 0.3 mm wide!

(14/18)

Let’s compare the prints to a top of the line resin casting.

I bought myself the Balaton Models K-700 Kirovets as a Christmas present (at my age that’s the only way you get what you want) - it retails for €100 and it’s an absolute beauty.

(15/18) https://www.balatonmodellshop.co.uk/K-700A-1/35

I bought myself the Balaton Models K-700 Kirovets as a Christmas present (at my age that’s the only way you get what you want) - it retails for €100 and it’s an absolute beauty.

(15/18) https://www.balatonmodellshop.co.uk/K-700A-1/35

Here are some comparison shots of the 3D-prints (dark grey) and the Balaton resin castings (light).

Note: I make NO claim whatsoever of being anywhere near the Balaton guys level of skill in modeling, this is just a comparison of detail!

(16/18)

Note: I make NO claim whatsoever of being anywhere near the Balaton guys level of skill in modeling, this is just a comparison of detail!

(16/18)

To me, the only real difference where the 3D-print is behind is in curved surfaces - here the casting is definitely smoother.

I should mention though that this is straight from the printer - some sanding will probably remove the hard edges between the layers.

(17/18)

I should mention though that this is straight from the printer - some sanding will probably remove the hard edges between the layers.

(17/18)

Read on Twitter

Read on Twitter