I tweet lots about bridges; but there is so much to discuss and talk about! So I’m doing my own take on the Christmas Lectures by doing a series of #civengexplained threads each night this week, to better explain how bridges work #bridge #construction #civilengineering #highways

Caveat: I’m not a bridge designer, I build someone’s else’s design. So go easy if I get something wrong – but I’m hoping non-bridge people will get something out of this! I’m a highways engineer so we’ll look at it from a roads angle- but fundamentals are the same.

So; what is a bridge? A bridge is a structure that carries something over something else. It can be a road, railway, pipeline, conveyor, over other roads or railways, canals and rivers, valleys, or the sea. Sometimes bridges are over other bridges!

The UK Design Manual for Roads & Bridges classes structures as anything greater than 0.9m diameter (a large pipes). Structures includes bridges, culverts, tunnels, retaining walls, barriers, masts, fences, gantries, signs, lighting, buildings and utilities.

Bridges are usually two flavours; underbridges or overbridges. You cross the main asset, so if a small road goes over a motorway, the small road is the ‘overbridge’, not the motorway ‘underbridge’. This is purely a naming thing, a bridge is still a bridge.

So what happens if a motorway crosses a railway line; both major assets, right? You usually revert to which came first, typically the rail line was there first so the motorway goes either over or under the rail line. Or, however the asset owner names the structure.

“Ok then, when does an underbridge become a looong tunnel?” I hear you shout. For roads, easy; the DMRB defines a tunnel as anything having a soffit (ceiling) longer than 150m. It’s an important distinction as tunnels require fire prevention, CCTV, monitoring, emergency plans etc

The upgrade to Junction 6 of the Coventry inner ring road involved covering the road over to make new walking routes – the ‘lid’ was deliberately kept to 140m to class it as a wide bridge; 10m longer would make it a tunnel and increase costs with the tunnel system requirements.

If you haven’t done so already, now might be a good time to get a tea and biscuit/cake slice as we dive into……..bridge terminology. To learn about bridges, you must first know it’s constituent parts - 'The elements of a bridge…'

First, the foundations. I’ll do a foundations thread this week to fully explain, but for now all you need to know is this: Foundations connect the bridge to the ground. They support it and keep it stable. With no foundations, you have no bridge.

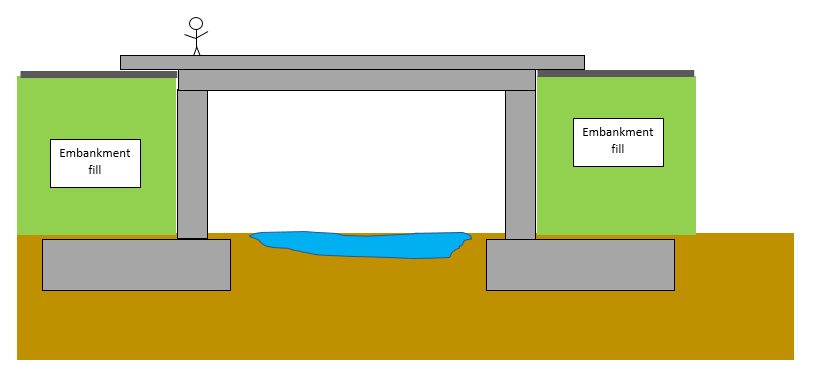

Next, the foundations connect to the abutment. Basically these are the ‘sides’ of the bridge, the exposed walls that you see. Some bridges don’t have them and there are different ways of building them. Abutments can sometimes refer to the whole bridge-end elements.

Bankseats. Some bridges have ‘em, some don’t. These are like mini-abutments, but are used just to connect or support the deck ends. So-called because often they are ‘seated’ on the ‘embankments’?

Bearing shelf, or bearing gallery. Some bridges have bearings which help the bridge to move. Bearings need regular inspection and maintenance so are fitted into an accessible area. Sometimes bearing are on supports/columns with no built-in methods of access.

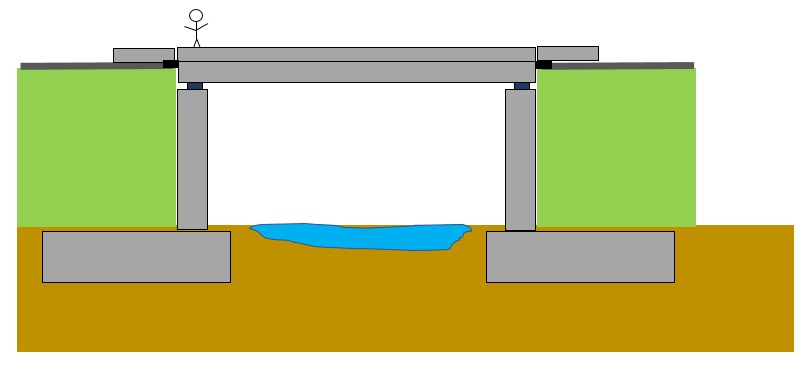

Bearings: Devices that help the bridge move. I’ll do a thread on bearings this week. Connects the deck to the abutment, bankseat or piers. Comes in various types such as fixed, sliding, pot, free-range, organic and vegan (the last two may be made-up)

Piers or columns (also called supports). Features that support the deck along the deck span. Columns used for cylinder-shaped supports, piers generally for everything else, except for on massive cable-stayed/suspension bridges they’re called towers.

Deck; fairly self-explanatory – it’s the section that spans between the abutments and supports. It supports the infrastructure we’re carrying across. Some bridges can have multiple decks or 'hidden' decks for strength.

Parapet: The edge protection that helps stop you falling off. Parapets can be made from various materials and can be a feature of the deck, abutments and retaining walls amongst others. On roads bridges they also stop vehicles going off the edge.

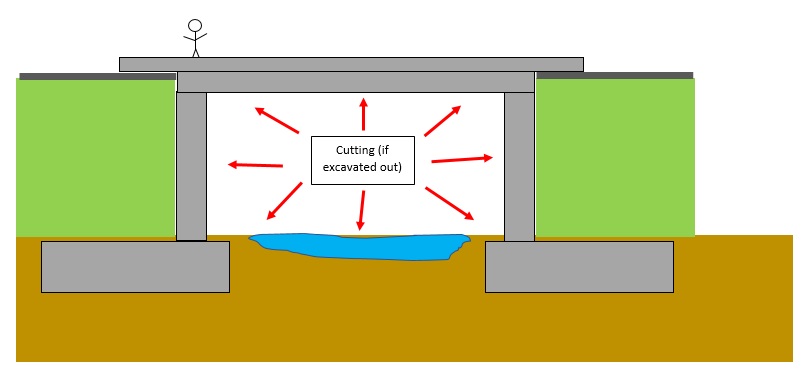

Embankments & cuttings: Embankment is when the ground is built up, cuttings are when the ground is reduced (excavated out). Sometimes they are part of the structure, sometimes they provide the surrounding ground approaches to the bridge.

Concrete: One of humankind’s best inventions, a material made of cement, sand, stone and water that goes hard when mixed together. Like mixing pastry and baking it in an oven.

Rebar: steel bars which are cut, bent and fixed into place to be cast into concrete. Together this forms ‘reinforced concrete’, an extremely strong and durable material. Concrete works well with compressive (downwards/pushing forces), steel is good in tension (stretching/bending)

Steel: As well as rebar it can also be used for beams, cables, strands, sheeting and decking. Steel is also used for parapets, vehicle restrain barriers, fencing and lighting columns which form part of ancillary fittings to a bridge.

Precast concrete – reinforced concrete elements which are cast in a fabrication yard off-site for better quality control and speed, and then brought to site and fitted together, similar to a Lego set (if the bricks were 1t concrete panels, for example).

There’s plenty of other weird and wonderful elements and features of bridges, but these are the basics and should help you with spotting bridges in the wild, or showing off to your non-bridge-learned friens, or fitting in at a bridge nerds' quiz night....

So now we have an idea of what parts make up a bridge, I’m going to run through some typical types of bridges. Remember these are typical examples, each structure is different and can be named/treated differently by the asset owner.

The rules aren’t 100% on any of this, so the tagline for this lecture is “The idiots guide to bridge types” (That’s two caveats I’ve shoe-horned in now).

Bridge design is affected by a multitude of things, and is why we see such a variety of structures across the world. Purpose, location, geography, time, cost, complexity, availability of materials, are just some of the factors that influence bridge designs.

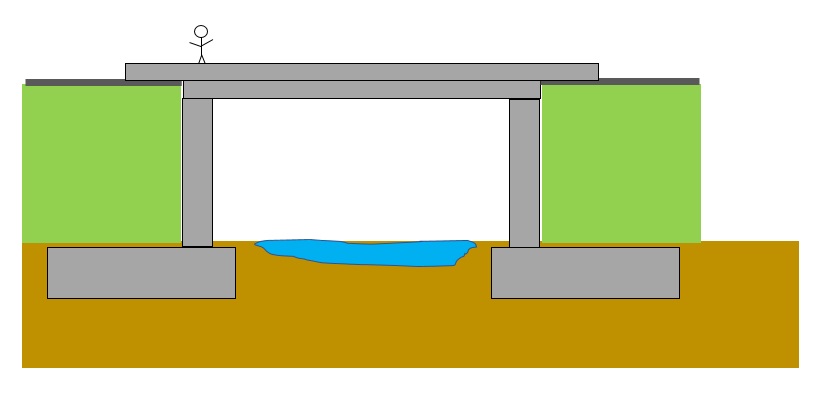

There are two structure types; integral and non-integral. An integral bridge means everything has fixed connections – the structure acts as one huge monolithic object. If you had a crane and picked it up at any point, the whole structure would lift as one object.

Non-integral bridges have parts that allow the bridge to move. The deck is connected to abutments via bearings and joints – effectively it ‘floats’ and if you lifted the deck with the magic crane, the abutments would stay stuck on the ground. I’ll explain this concept later.

To start, some very basic bridge designs. These are simple and cheap. The simplest are precast single units – large boxes or pipes that are buried under a road or railway, voila: instant bridge.

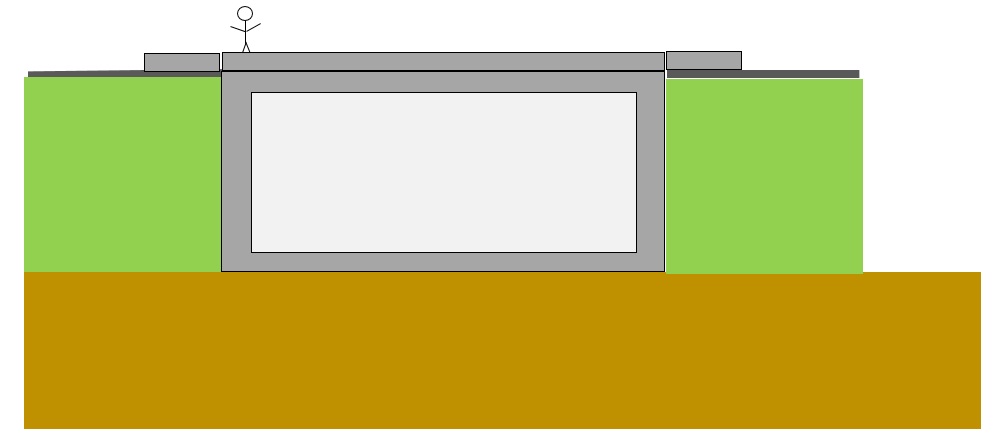

Then we have simple integral bridges – concrete abutments and bankseats with a single-span deck slab. The deck can be composite, made of beams and concrete slabs, or one large in-situ concrete deck slab.

Non-integral versions are similar but with movement joints, bearings and expansion gaps. You can see the movement joint as the grey strip running across the carriageway in this picture.

Then we have multi-span bridges, with supporting piers or columns allowing for longer bridges. On the left is an integral two-span bridge (one pier with 3 columns in middle), on the right is a 3-span non-integral bridge. (two piers of 3 columns each)

Viaducts – usually very long or tall multi-span bridges. When does a bridge become a viaduct? There’s no official definition for highways (AFAIK) so it’s generally a naming convention based on the length & height. Pic1 is new A14 viaduct over River Ouse, Pic 2 M1 J19 viaducts.

Cable-stayed bridges – commonly confused with suspension bridges. The stays (cables) connect the deck directly to the support towers – so the deck isn’t suspended as it is directly supported. The Queensferry Crossing is a great example of a cable-stayed bridge. Pic2 is Dartford.

Suspension bridges – support cables hang between support towers, and stays connect the suspension cables to the deck. The Forth Road Bridge (Pic 1) and Golden Gate (Pic 2) are suspension bridges.

Then we have trusses – complex steelwork members which act as one huge beam to create a span.. We all know triangles are strong, right? Trusses make use of triangles to act as a giant beam. Very popular in America and in the UK for footbridges: these types are bow Warren trusses:

There are loads of other types - swing & lifting bridges, sliding bridges, transporter bridges etc, but these are more unique and more well-known about! I'm going to go through the most basic fundamentals - once you know the basics, the more complicated stuff is easier to get!

So, schedules as follows:

Monday - Intro to Bridges

Tuesday - Foundations

Wednesday - Deck Construction & Destruction

Thursday - Bearings & movement joints

Friday - Wingwalls, waterproofing and wevrything else

I won't commit to times, we'll assume "evening" time!

Enjoy!

Monday - Intro to Bridges

Tuesday - Foundations

Wednesday - Deck Construction & Destruction

Thursday - Bearings & movement joints

Friday - Wingwalls, waterproofing and wevrything else

I won't commit to times, we'll assume "evening" time!

Enjoy!

Image credits as follows:

Queensferry crossing: https://images.app.goo.gl/G3fKPbqfMTKwZg956

A14 River Ouse viaduct: https://images.app.goo.gl/dTKHu7qEAqHmNasLA

Forth Road Bridge: https://images.app.goo.gl/i7XgpRnLckHJmmTP8

Golden Gate Bridge: https://images.app.goo.gl/2j6mQ8f4rBJnkwJM8

Hindhead Tunnel: https://images.app.goo.gl/tPKe4APuqxryZuyE7

and Google Streetview

Queensferry crossing: https://images.app.goo.gl/G3fKPbqfMTKwZg956

A14 River Ouse viaduct: https://images.app.goo.gl/dTKHu7qEAqHmNasLA

Forth Road Bridge: https://images.app.goo.gl/i7XgpRnLckHJmmTP8

Golden Gate Bridge: https://images.app.goo.gl/2j6mQ8f4rBJnkwJM8

Hindhead Tunnel: https://images.app.goo.gl/tPKe4APuqxryZuyE7

and Google Streetview

Otherwise all other images and sketches are my own from previous schemes worked: A5-M1 Link, A14 Cambridge to Huntingdon Improvement.

Read on Twitter

Read on Twitter