Inspired by @ExeterHipUnit thread have a little bit of #ortho #hip history from the Museum in the @wrightington16 hip centre.

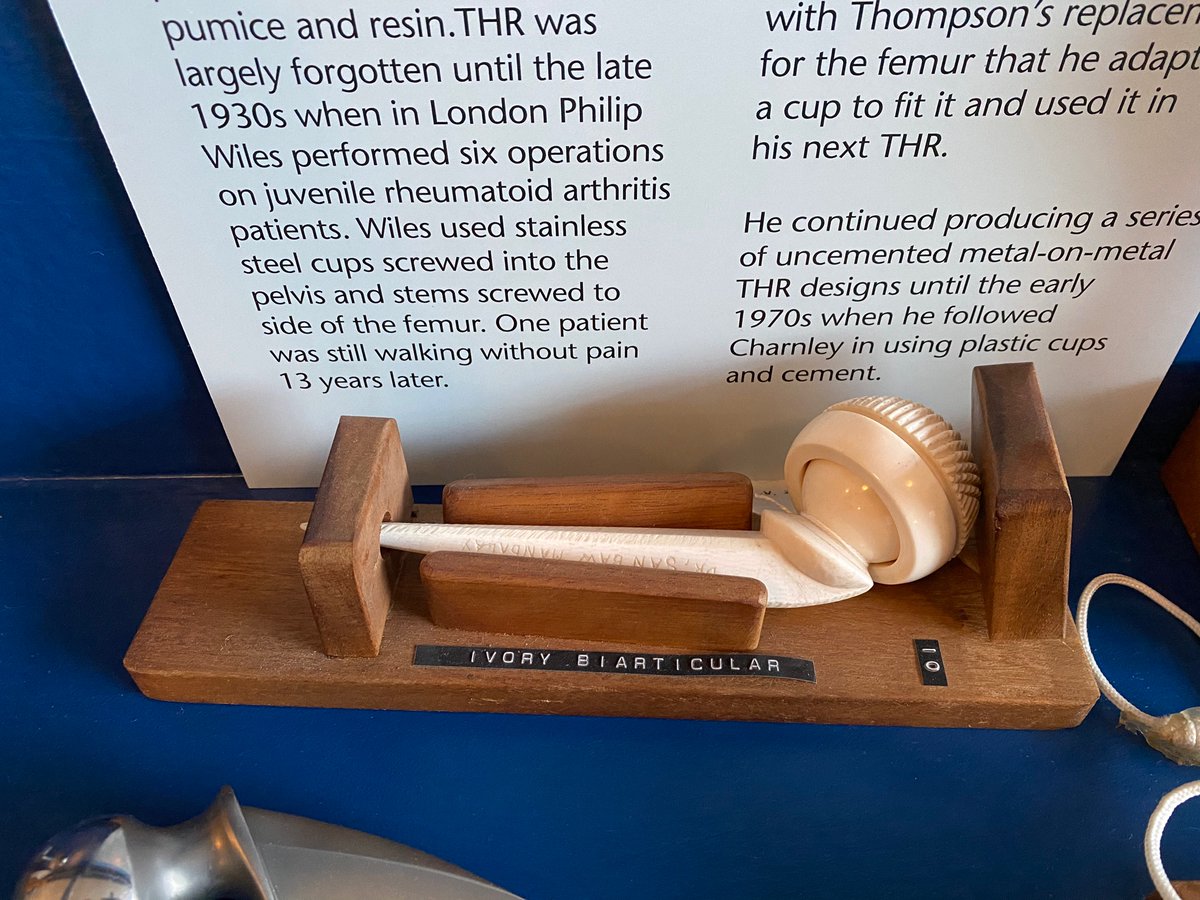

The early hip replacements were pioneered by Gluck in the 1980’s. These were made from ivory and cemented in with plaster pumice and Resin 1/

The early hip replacements were pioneered by Gluck in the 1980’s. These were made from ivory and cemented in with plaster pumice and Resin 1/

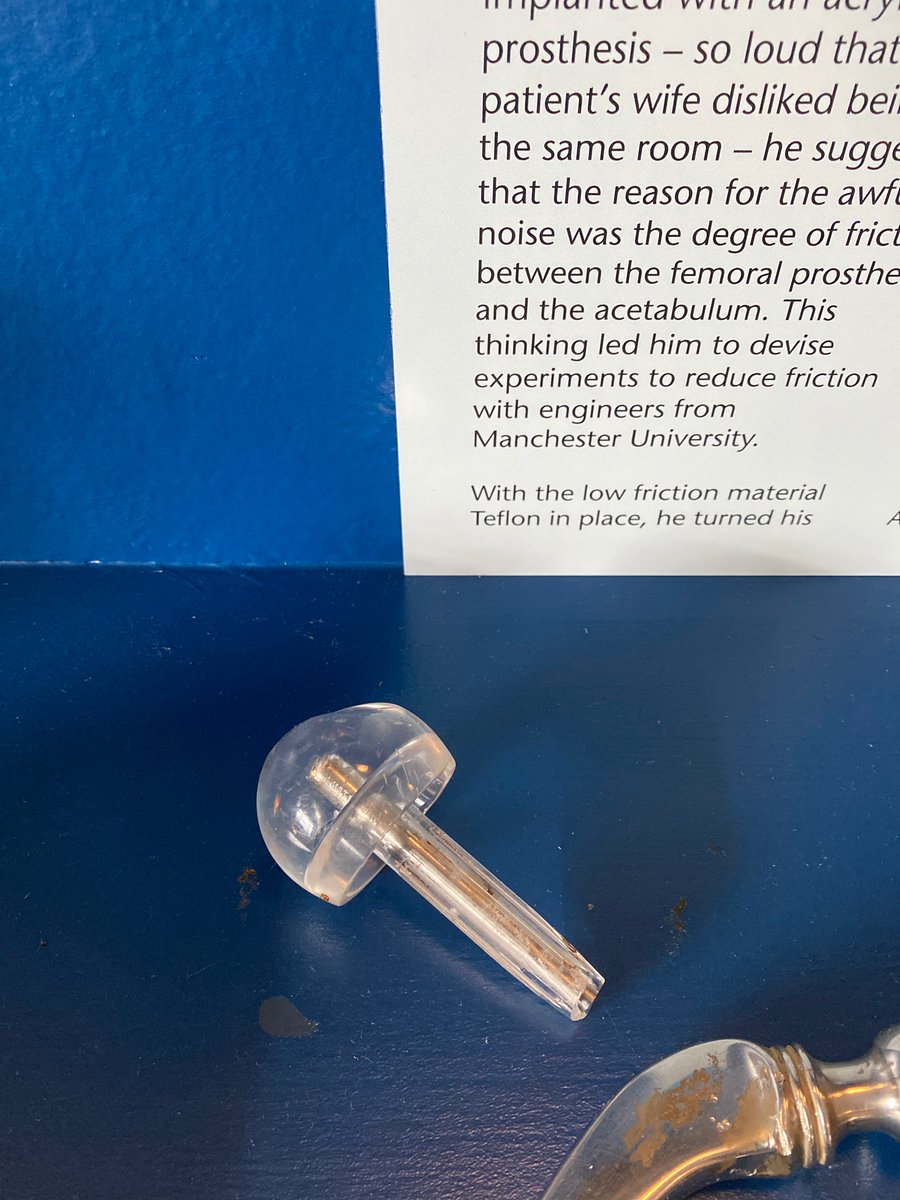

Charnley experimented with acrylic Judet- but patients and family members noted the hip squeaked. Leading him to believe this was due to friction 2/

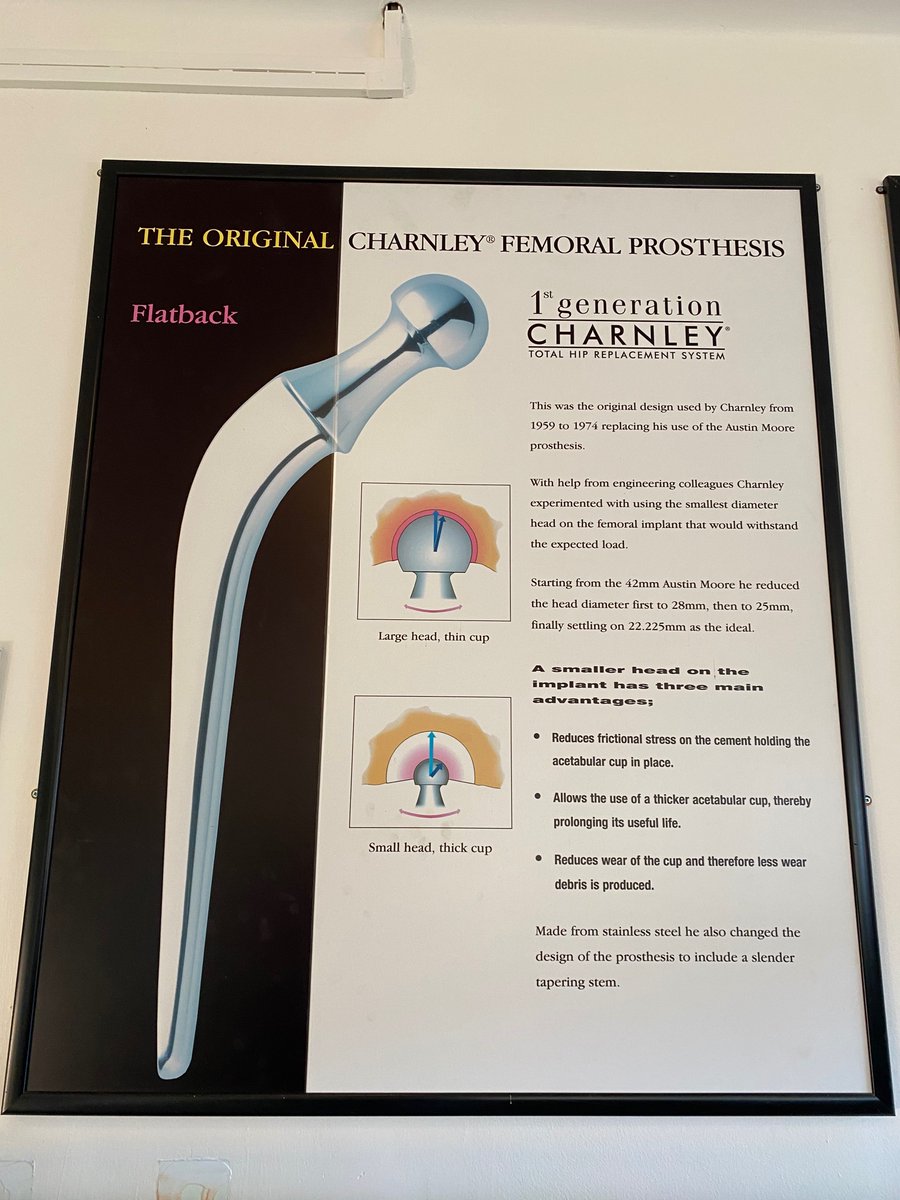

He trialled Teflon as a bearing surface and used this alongside a 42mm Austin Moore. He then reduced the diameter of the femoral head to 28 then 22.225mm.

The “low frictional torque Arthroplasty”

Unfortunately Teflon failed as a bearing surface and caused granuloma formation 3/

The “low frictional torque Arthroplasty”

Unfortunately Teflon failed as a bearing surface and caused granuloma formation 3/

This was to be considered one of his greatest setbacks.

A chance encounter with high density polyethylene led Charnley to believe he had found the right bearing surface. Rigorous testing was performed including placing some in his own leg to assess for soft tissue reaction! 4/

A chance encounter with high density polyethylene led Charnley to believe he had found the right bearing surface. Rigorous testing was performed including placing some in his own leg to assess for soft tissue reaction! 4/

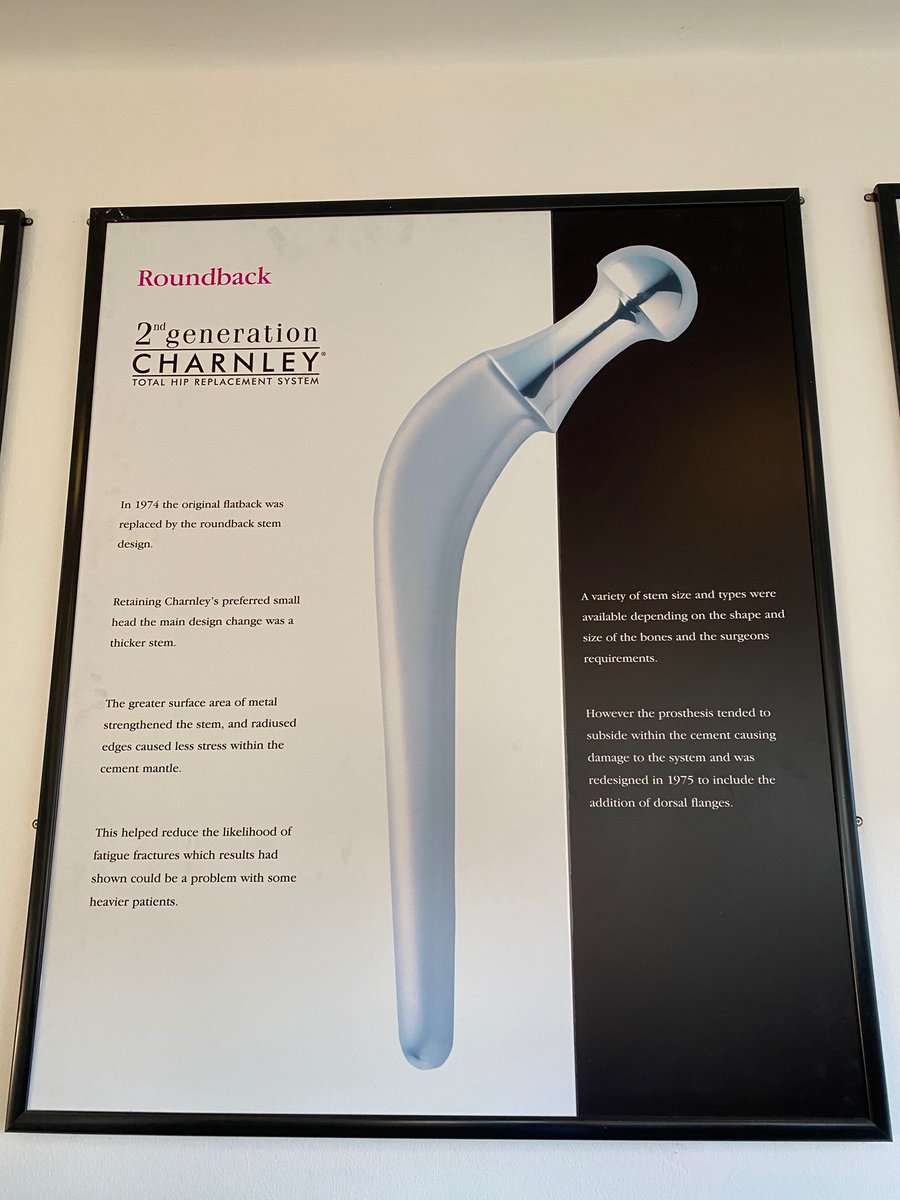

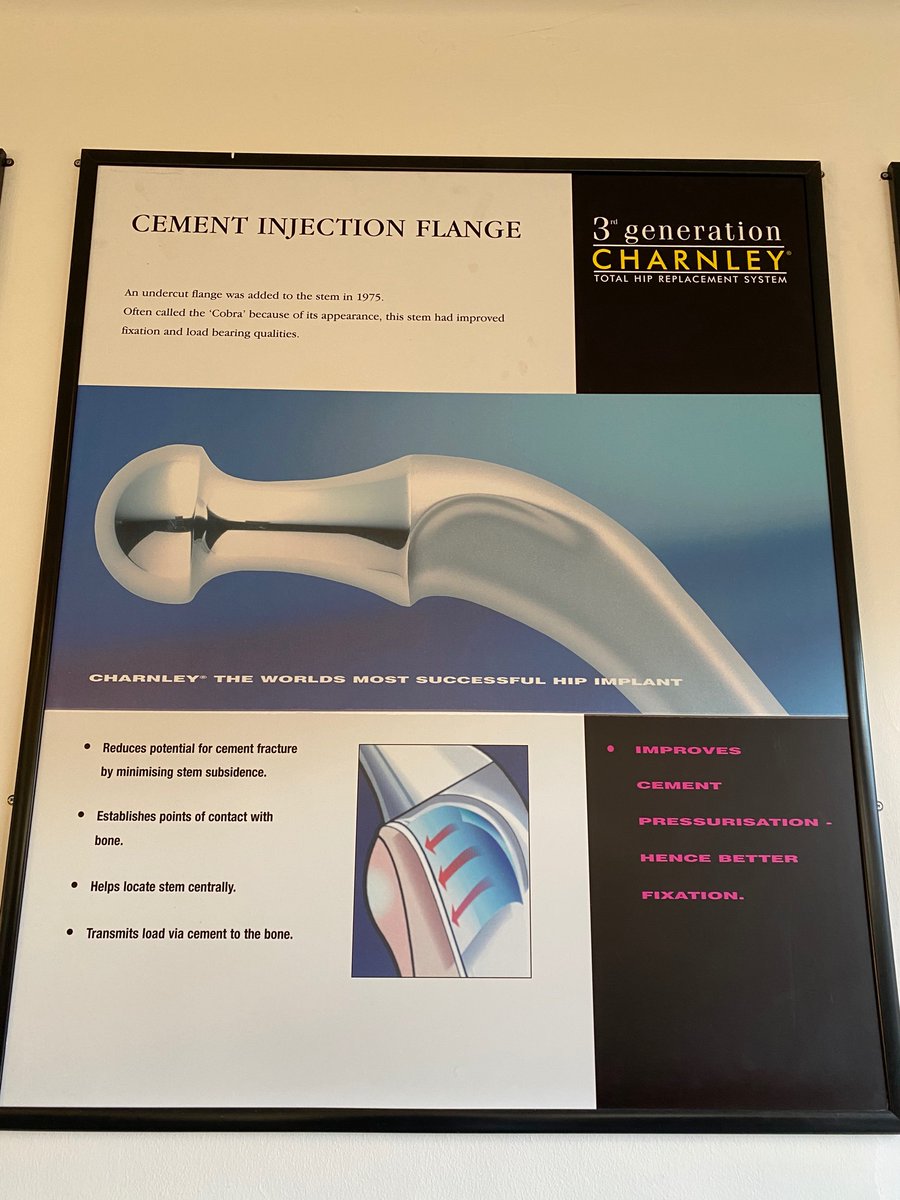

The first “Charnley flatback” was implanted in 1959 and continued until 1974. It subsequently underwent several modifications 5/

Read on Twitter

Read on Twitter