1/ With Japan's Nippon Steel announcing carbon neutrality by 2050, what could this mean in the context of the ambitious  2030 hydrogen target? @TakeshiKuramo @Ma_Deutsch @gnievchenko @sstapczynski @RENEWIndustry #hydrogen

2030 hydrogen target? @TakeshiKuramo @Ma_Deutsch @gnievchenko @sstapczynski @RENEWIndustry #hydrogen

2030 hydrogen target? @TakeshiKuramo @Ma_Deutsch @gnievchenko @sstapczynski @RENEWIndustry #hydrogen

2030 hydrogen target? @TakeshiKuramo @Ma_Deutsch @gnievchenko @sstapczynski @RENEWIndustry #hydrogen

2/  revealed earlier this week plans to consume 10 Mt of hydrogen by 2030. This equals 333 TWh of hydrogen. In a hydrogen economy of that scale by 2030 the Japanese steel sector should play a key role, don't you think? https://de.reuters.com/article/uk-japan-hydrogen-power-idUKKBN28I0BH

revealed earlier this week plans to consume 10 Mt of hydrogen by 2030. This equals 333 TWh of hydrogen. In a hydrogen economy of that scale by 2030 the Japanese steel sector should play a key role, don't you think? https://de.reuters.com/article/uk-japan-hydrogen-power-idUKKBN28I0BH

revealed earlier this week plans to consume 10 Mt of hydrogen by 2030. This equals 333 TWh of hydrogen. In a hydrogen economy of that scale by 2030 the Japanese steel sector should play a key role, don't you think? https://de.reuters.com/article/uk-japan-hydrogen-power-idUKKBN28I0BH

revealed earlier this week plans to consume 10 Mt of hydrogen by 2030. This equals 333 TWh of hydrogen. In a hydrogen economy of that scale by 2030 the Japanese steel sector should play a key role, don't you think? https://de.reuters.com/article/uk-japan-hydrogen-power-idUKKBN28I0BH

3/ Disclaimer: I'm not an expert on Japan at all, but some general insights from the perspective of the decarbonization of steel may be interesting in this context.

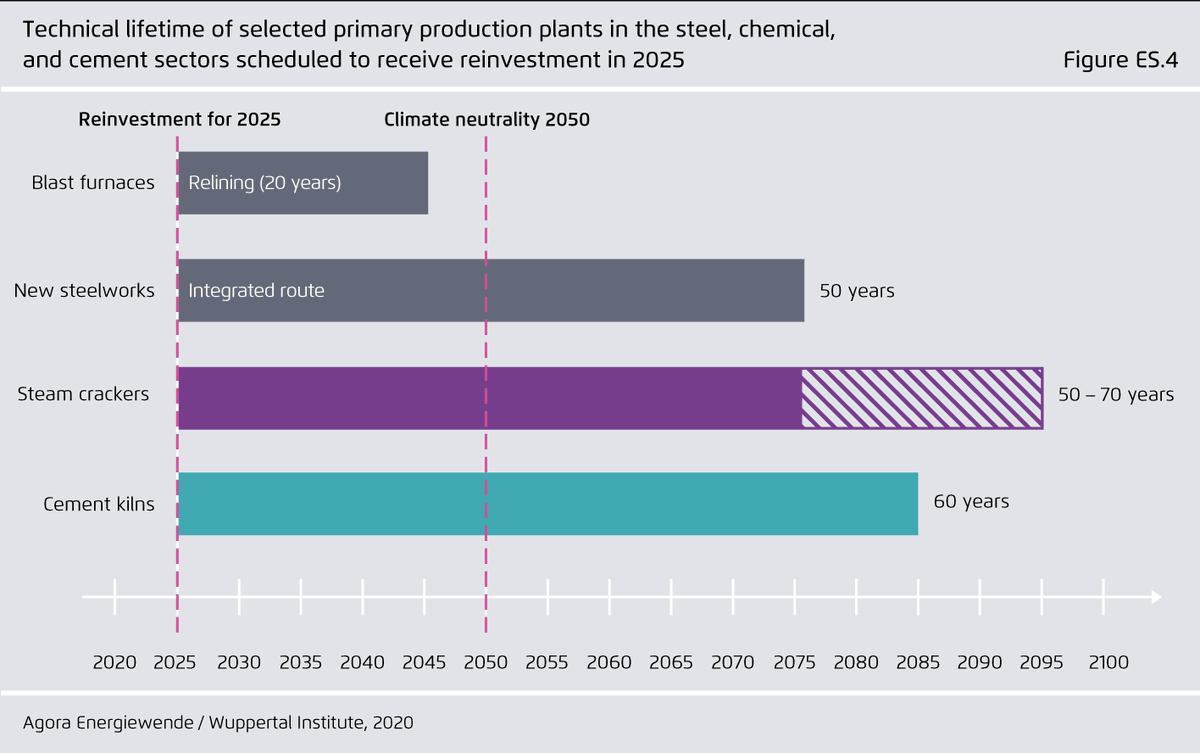

4/ Given Japan's pledge to become climate-neutral by 2050, the long lifetimes of industrial assets mean that any industrial plant you invest in should use technologies that are compatible with climate neutrality 2050 from now on.

5/ What are the reinvestment cycles of the Japanese steel industry? I don't know, but typically a coal-based blast furnace has a lifetime of 20 years. Assuming a normal distribution, you will have 50% of coal-based blast furnaces that reach the end of their lifetime before 2030.

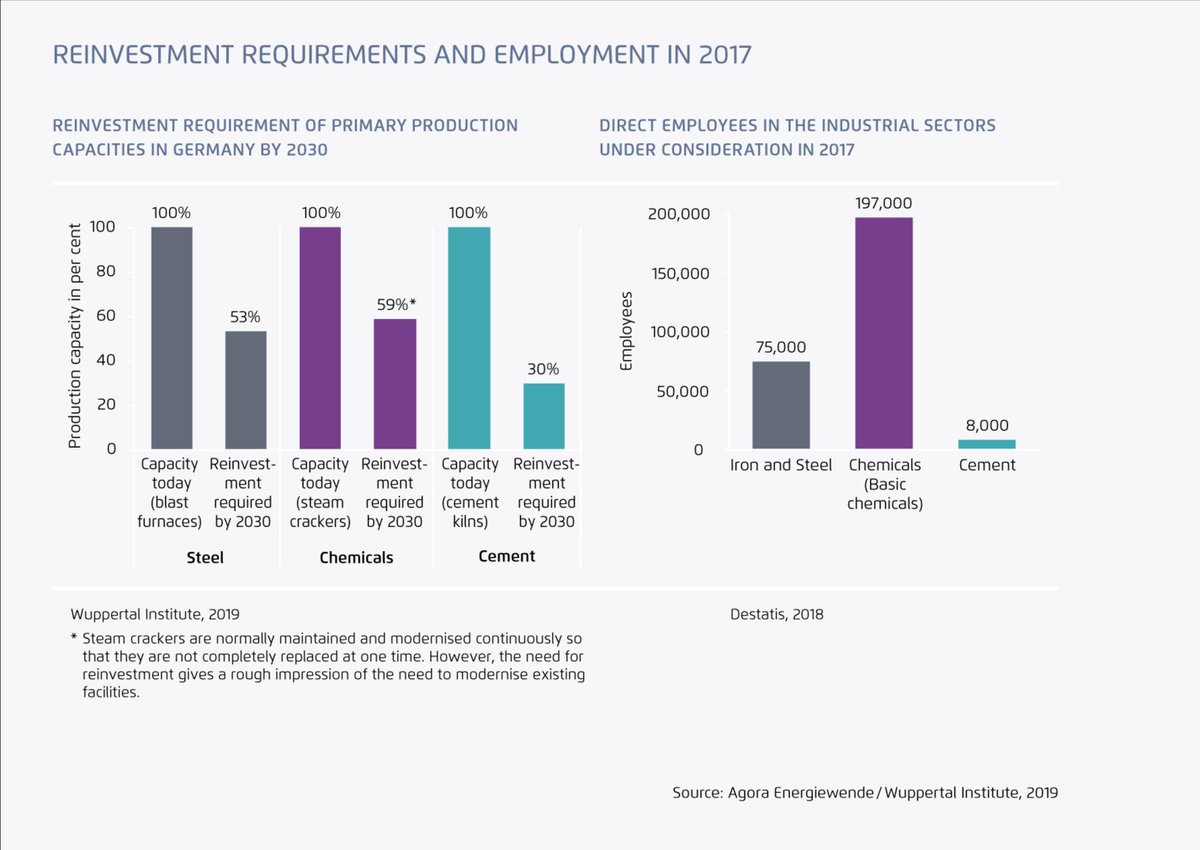

6/ We did this analysis for primary steel in  , which is the world's 7th biggest steel producer.

, which is the world's 7th biggest steel producer.

Result: 53% of primary steel need reinvestment before 2030

, which is the world's 7th biggest steel producer.

, which is the world's 7th biggest steel producer. Result: 53% of primary steel need reinvestment before 2030

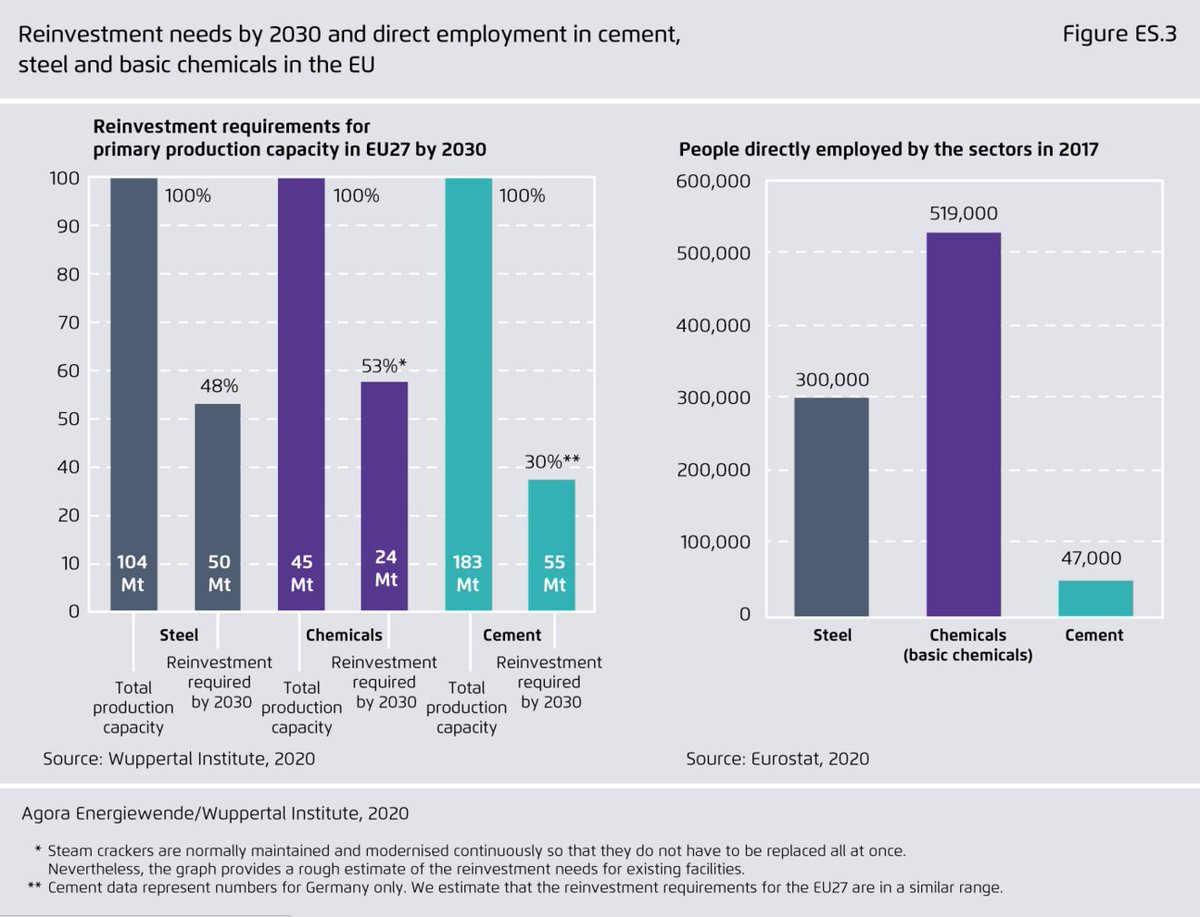

7/ We did this analysis for primary steel in  , which as a bloc is the world's 2nd biggest steel producer.

, which as a bloc is the world's 2nd biggest steel producer.

Result: 48% of primary steel need reinvestment before 2030

, which as a bloc is the world's 2nd biggest steel producer.

, which as a bloc is the world's 2nd biggest steel producer. Result: 48% of primary steel need reinvestment before 2030

8/ Therefore, we can assume the case is probably not so different in Japan: ~50% of primary steel capacity reach the end of its lifetime by 2030 and need reinvestment to sustain current production levels.

9/ Reinvestments into conventional coal-based blast furnaces in the 2020s will create a carbon lock-in and are at a high risk of becoming stranded assets.

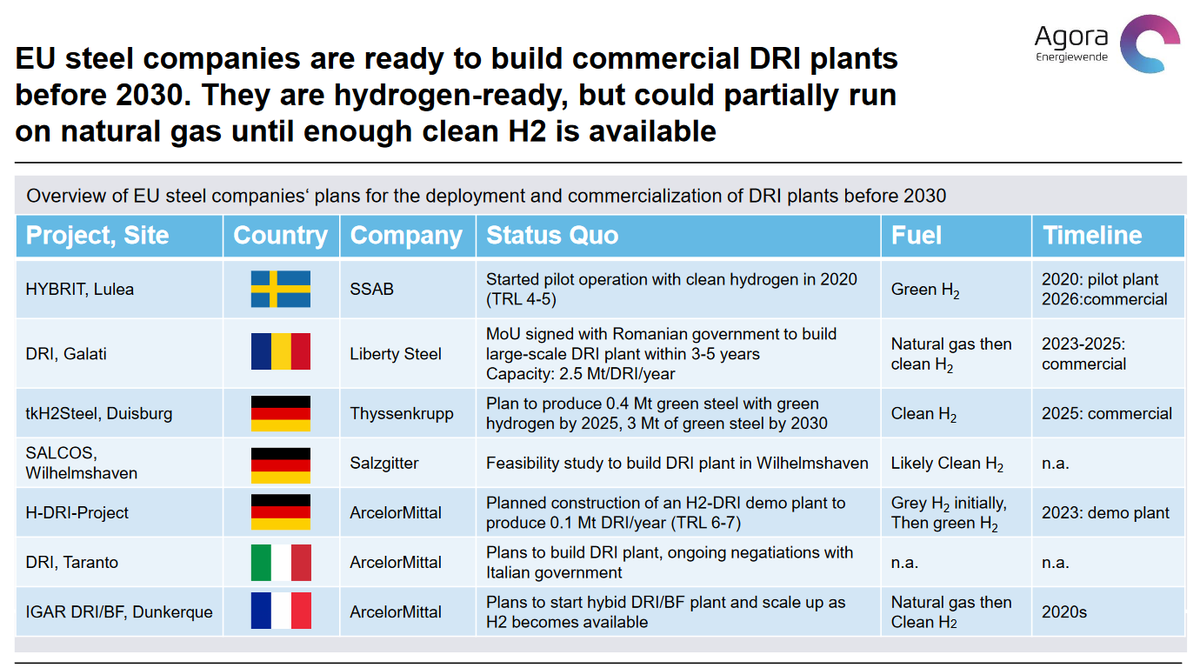

10/ Hydrogen-based DRI technology is ready for deployment now. China is building the first hydrogen-based commercial DRI plant by 2021 https://www.tenova.com/news/press-media/press-releases/detail/first-hydrogen-based-energiron-dri-plant-for-tenova-in-china/

12/ Let's do some numbers crunching for Japanese steel here:

Steel production 2019: 75 Mt primary steel

Reinvestment need 2030: 37,5 Mt (50%)

EF Blast furnace assumed: ~2 t of CO2/t of primary steel

EF DRI hydrogen: -1,8 t of CO2/t of primary steel (~-90%)

Steel production 2019: 75 Mt primary steel

Reinvestment need 2030: 37,5 Mt (50%)

EF Blast furnace assumed: ~2 t of CO2/t of primary steel

EF DRI hydrogen: -1,8 t of CO2/t of primary steel (~-90%)

13/ If Japan was to replace all blast furnaces that need reinvestment by 2030 with H2-based DRI it could:

1.) produce 38 Mt of H2-based green steel in 2030

2.) reduce emissions of primary steel by 68 Mt of CO2 compared to business as usual

1.) produce 38 Mt of H2-based green steel in 2030

2.) reduce emissions of primary steel by 68 Mt of CO2 compared to business as usual

14/ This amount of green steel would require ~44 TWh of H2* by 2030. This equals 13% of the target (333 TWh). I cannot imagine many applications where hydrogen use is such a no-regret option.

*assumes a ~70% H2/~30% natural gas use (some carbon needed for metallurgical reasons)

*assumes a ~70% H2/~30% natural gas use (some carbon needed for metallurgical reasons)

15/ Before sufficient amounts of clean hydrogen are available, DRI plants can operate on natural gas reducing emissions by -66% compared to the coal-based blast furnace route. These plants are H2-ready without any major retrofits.

16/ I'm very curious to learn more about Nippon Steel's plans. The article mentions "a new way of steelmaking using H2" that would cut emissions by 80%. Is it DRI or sth new? https://asia.nikkei.com/Spotlight/Environment/Nippon-Steel-pledges-to-be-carbon-neutral-by-2050

Read on Twitter

Read on Twitter