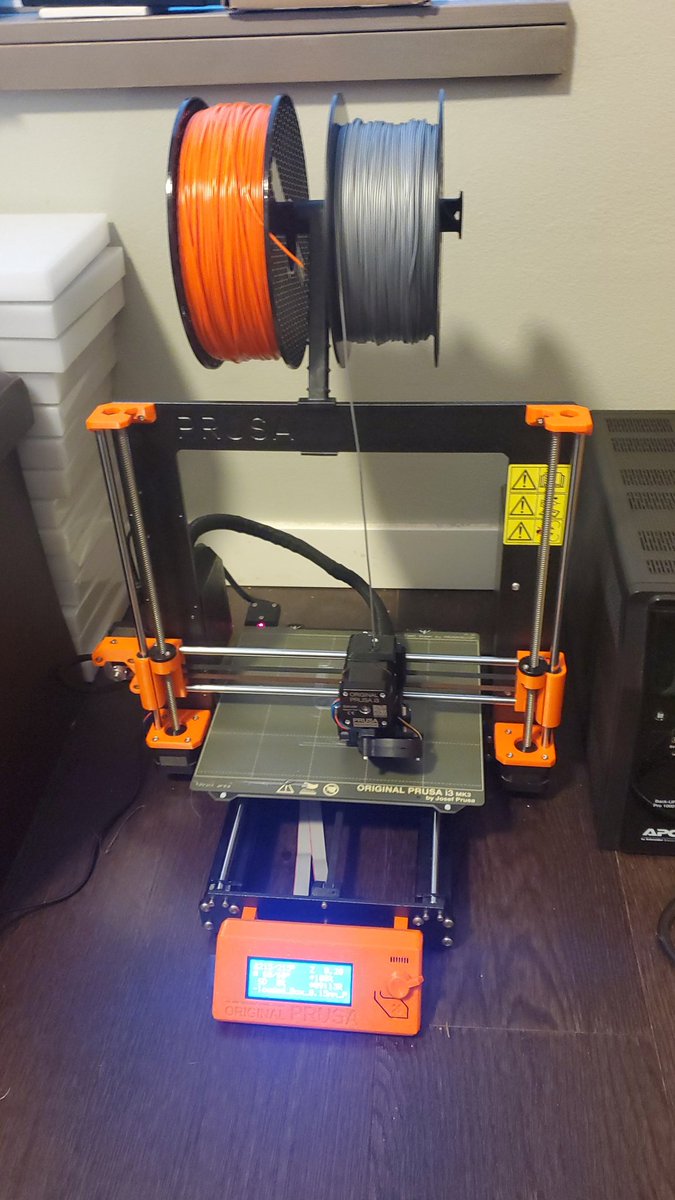

I assembled a 3d printer! After a week of on-off work assembling the thing, it's finally here and working! I want to use it to explore the limits of what is possible with off the shelf 3d printing tech and in this thread I will document my prints and what I learned from them.

After a while trying to get the high end sheet to work, I went back to the original and using simple PET filament printed some of the stuff that came with the SD card of the printer. I'm shocked how good it looks. Clearly the Prusa team has done a lot of work on the golden path.

That was with no tuning and no prior experience. Then I installed Prusa Slicer and went on a rampage on Thingiverse. First I printed this octopus in one piece, magnified to 150%. My 18month old seems to like it. (PLA is non-toxic, made from plant starch. https://en.m.wikipedia.org/wiki/Polylactic_acid)

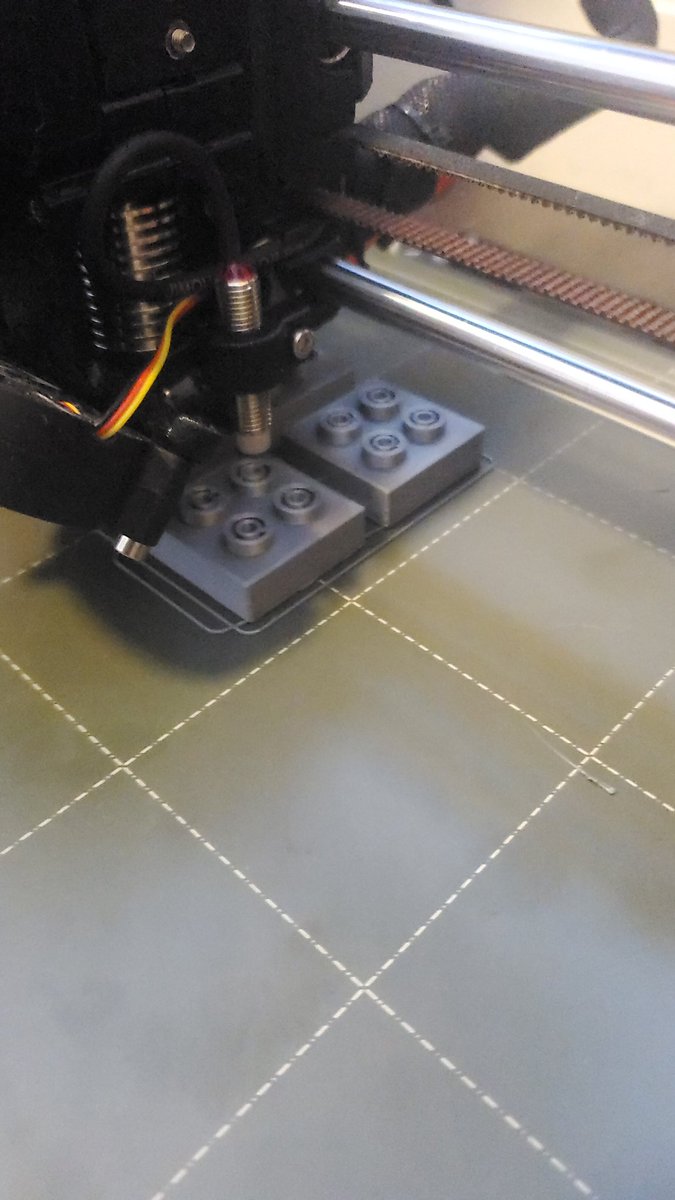

Next up, I wanted to push some boundaries. How about a 3d printed plastic ball bearing? Why not? The one on the right was magnified 2x, and printed in high detail. The one on the left, original size, works much better. https://www.thingiverse.com/thing:4628063

How about some compliant mechanisms? Yes! I printed this lovely switch in one piece. This video from Veritasium was my introduction to compliant mechanisms, and my mind was blown.

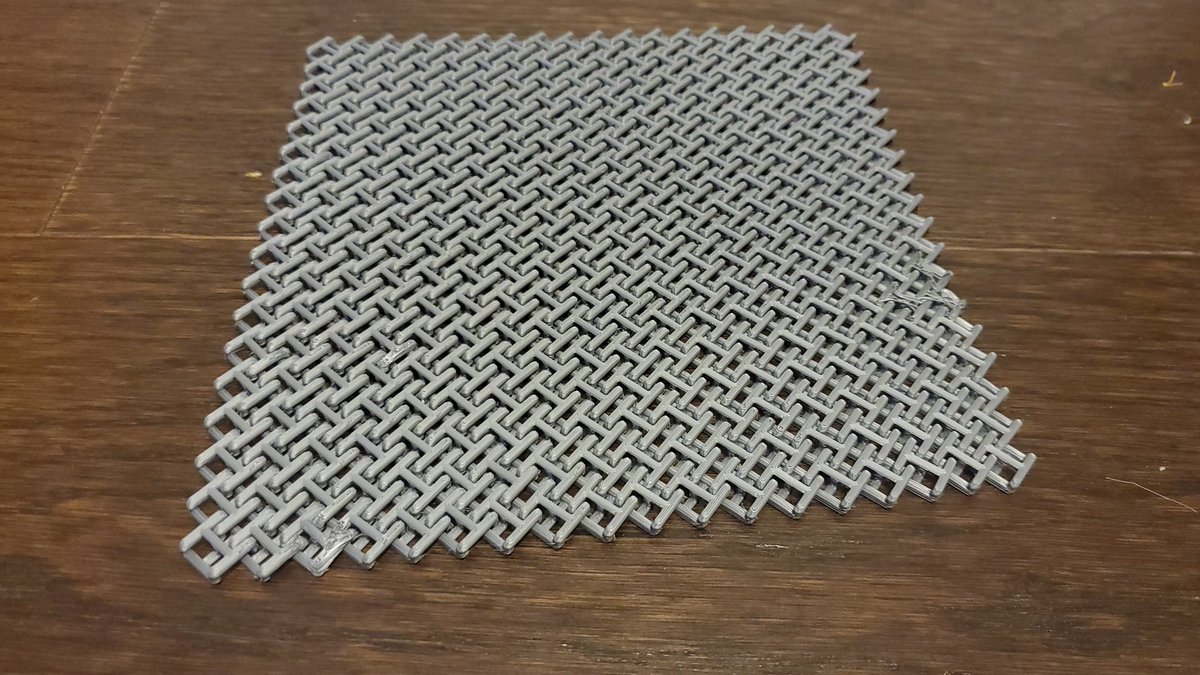

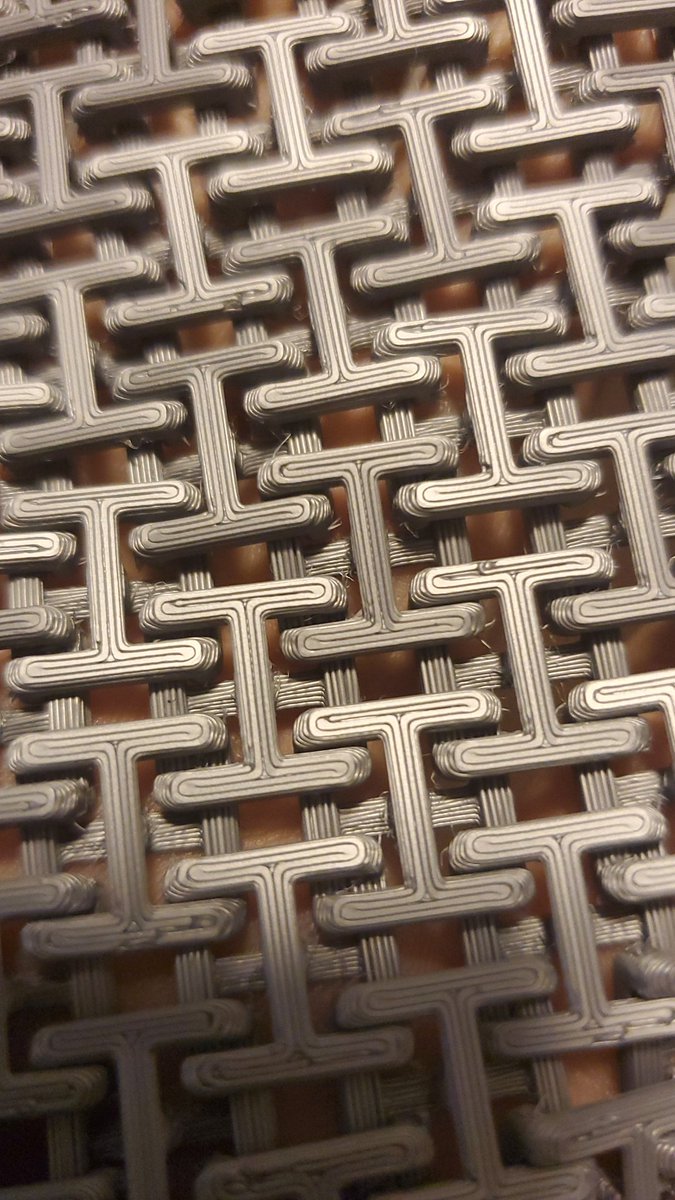

What about fabric? Can we print fabric? Look, it took 16 hours and had a couple of flaws, but it worked! OK, maybe more like chain mail, but still!

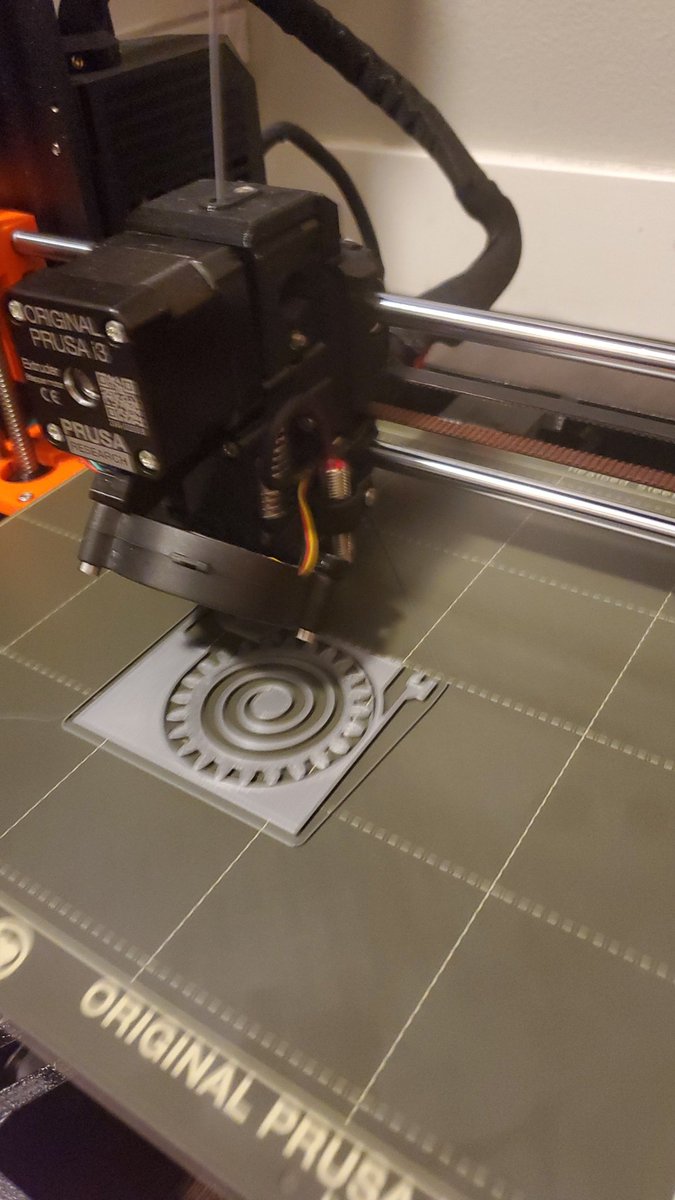

What next? I'm printing this amazing print in place, spring-loaded box by Sunshine. Complia t mechanisms for the win. Actually, just subscribed to his Patreon too  , the dude is a God among men. 8h44m to completion.

, the dude is a God among men. 8h44m to completion.

, the dude is a God among men. 8h44m to completion.

, the dude is a God among men. 8h44m to completion.

What can I do to push the boundaries after this? First I want to set up a workflow with octobalena by @MatthewCroughan, with a pi4 or balenaFin to manage the printer remotely. Maybe I can get PrusaSlicer on the same device so I can... https://github.com/MatthewCroughan/octobalena

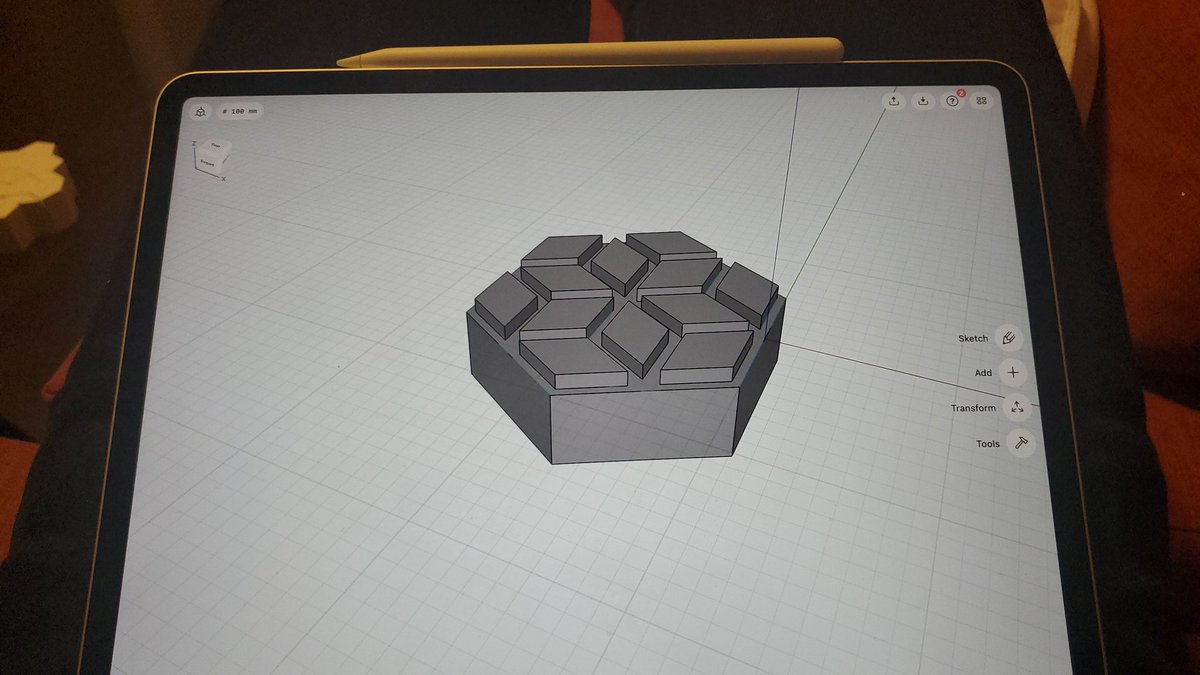

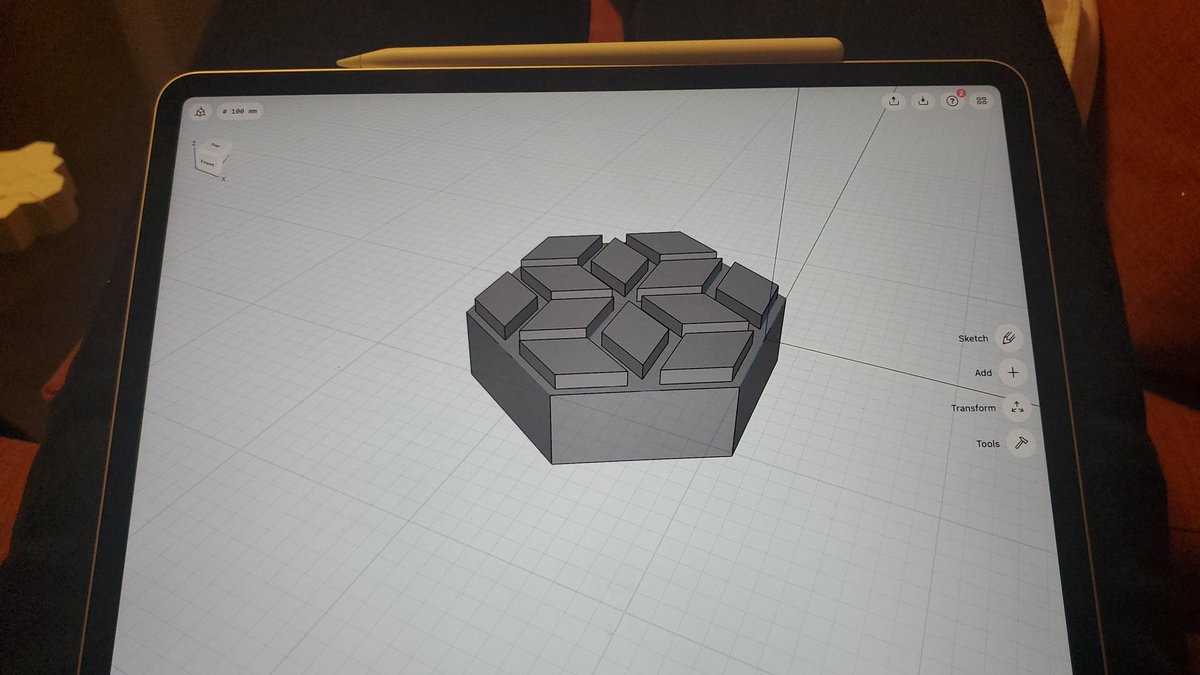

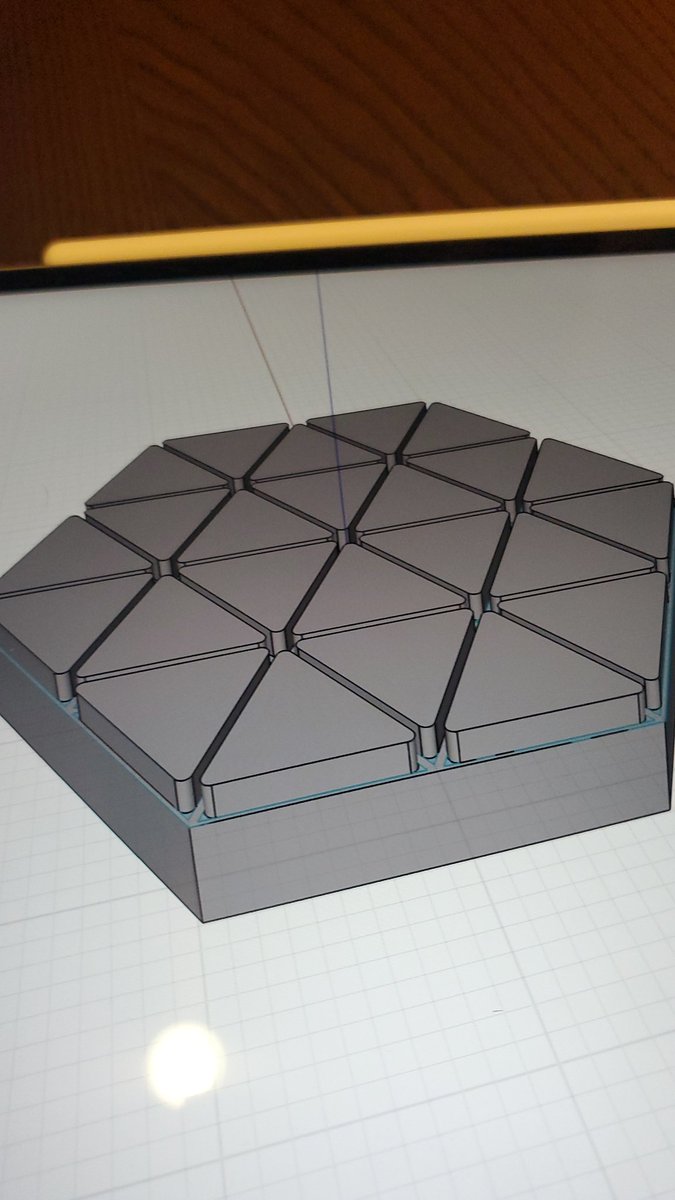

Use shapr3d from an iPad to design and send to the Slicer on the printer directly through the browser! I've never bought an apple device before, so this is a big deal, but the UX of shapr3d looks so amazing, I just have to try it out. https://www.shapr3d.com/

What other boundary - breaking things should I try to do with the printer? Alternatively I'm interested in printing things an 18month old will like if you have any suggestions.

My conclusion so far is that 3d printing is a lot easier than it sounded. I'm probably not your typical consumer, but I get frustrated trying to set up a smart home (though I run an IoT startup) and the 3d printer has been heaps of fun so far.

It's also given me a sense that physical things around me are much more malleable than they felt just a week ago. The feeling of having something printed from "nothing" is incredible. We'll see if it fades over time as I print my own stuff or if it will stay with me.

At the same time there is obvious room for improvement on the paradigm. From use of generative design to printing things to make printing easier, to using compliant mechanisms during a print as a way to print "impossible" designs, I'm full of ideas, and I would love to try them!

Oh, and #3dprinting gurus of Twitter, give me your tips, tricks, and deep criticism of my prints. I'm here to learn and want to hear your takes.

Printing update: I've now got the iPad with shapr3d, it's about as awesome as I imagined it. I can expect many years of fun designing with this baby. The Palette 2s pro is in the mail too

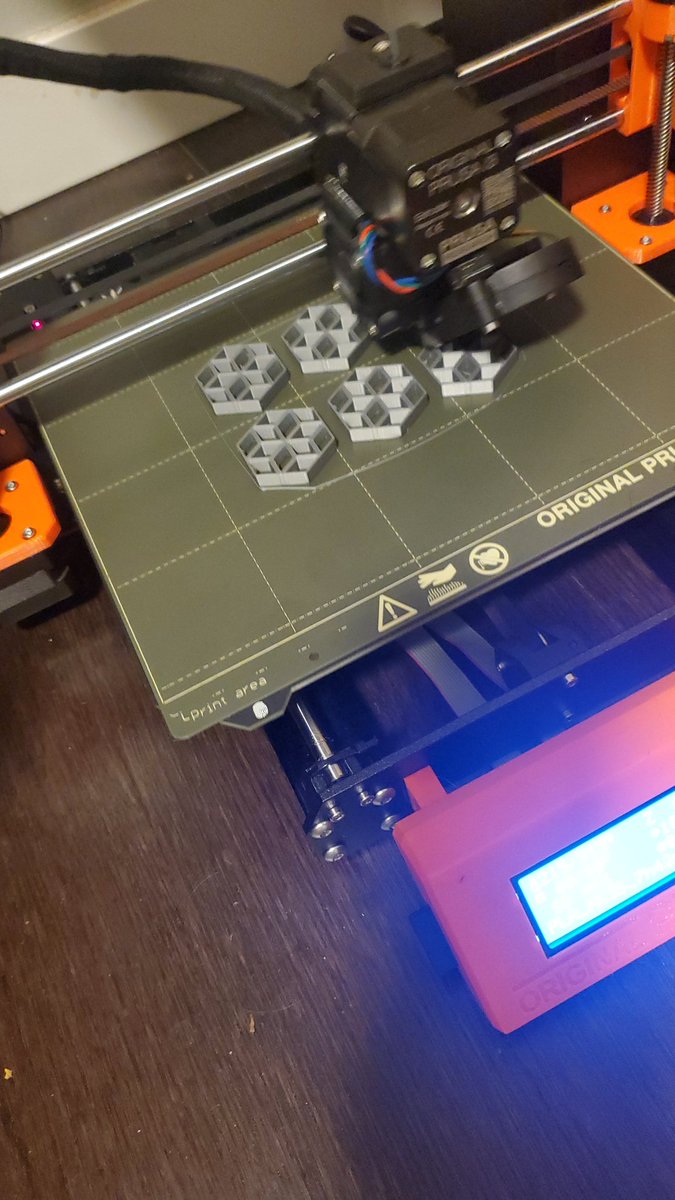

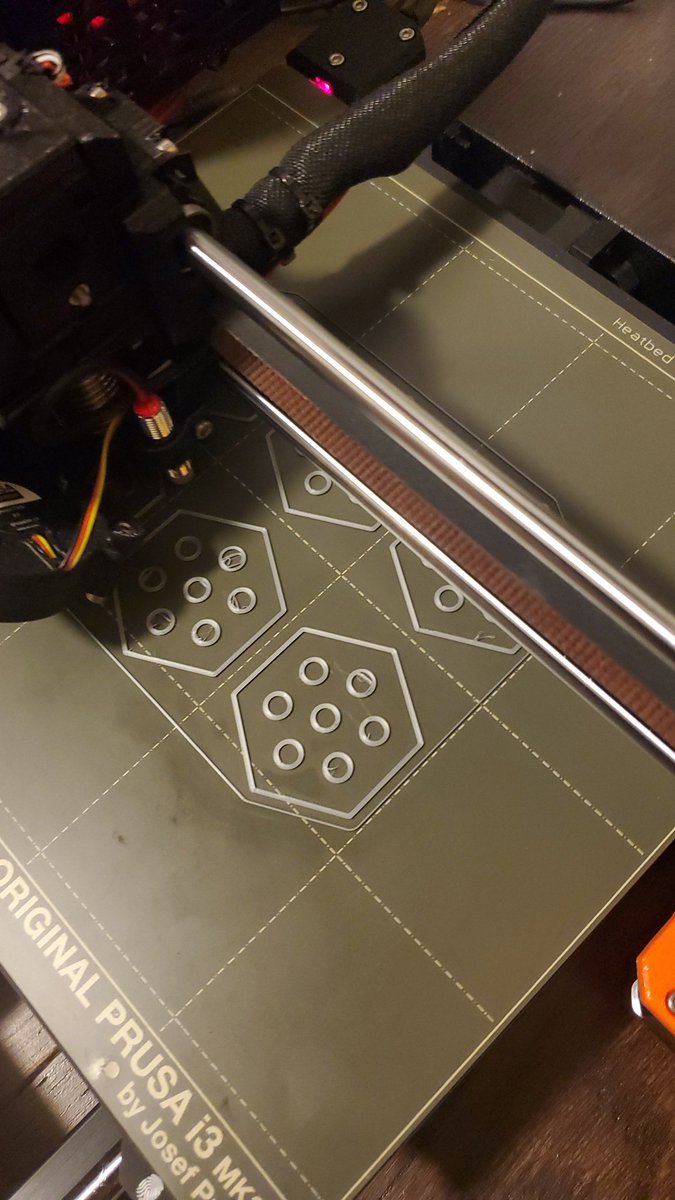

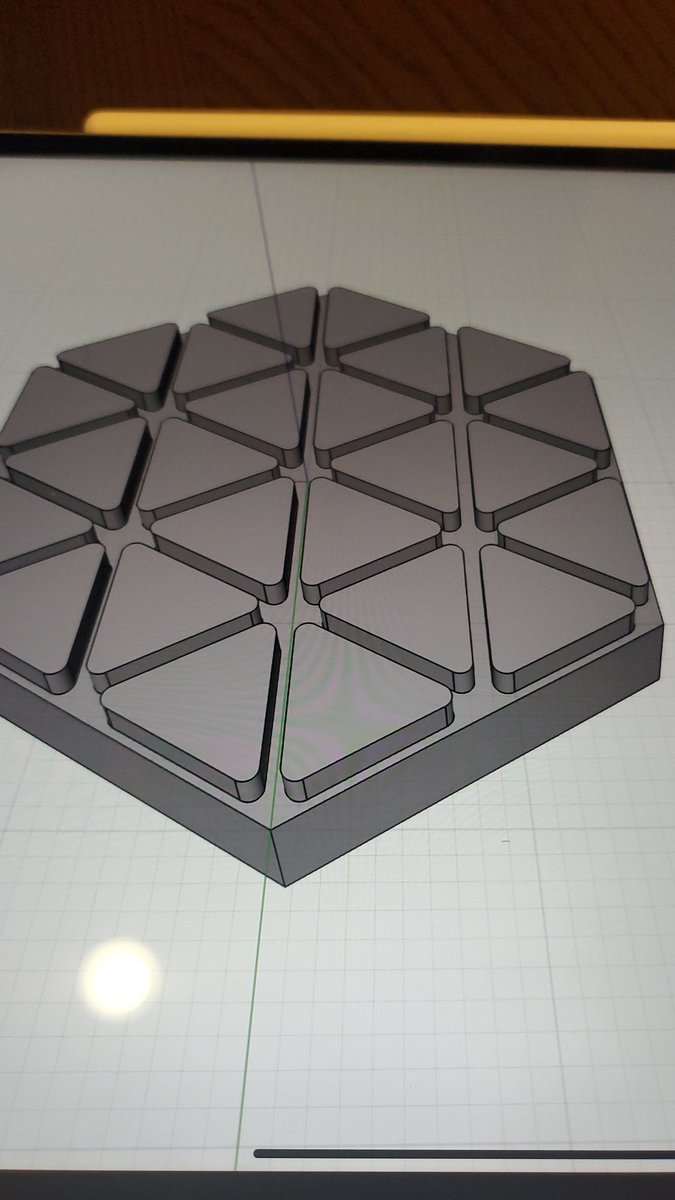

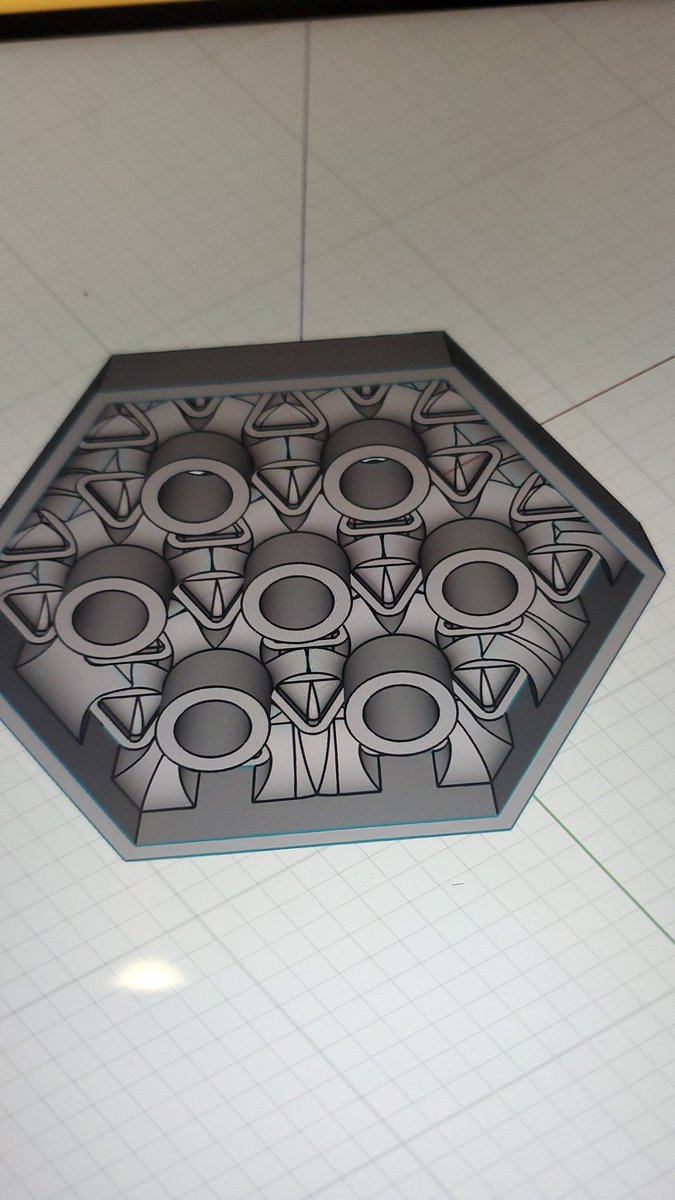

But of course one cannot leave well enough alone. Version 2 coming hot off the printer tonight, and it's hexagonal. You heard that right! Hexagonal not-Legos. Surprisingly tricky to figure out the layout of the bumps, and may still need a version 3 to nail it.

The next experiment I'm lining up is to try copperplating a print that includes parts made with conductive filament. The filament is already here, waiting for the copper. If that works, maybe simple or not so simple electronic parts are next!

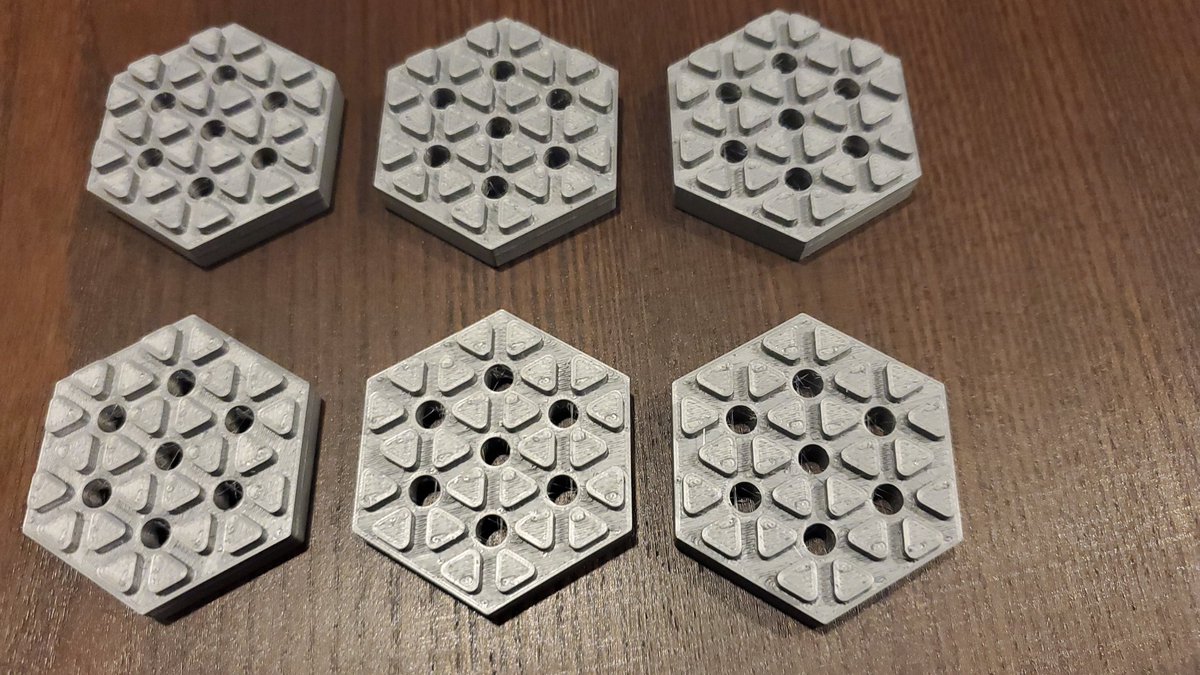

OK, so the snowflake not-Legos came out a bit tight, I need to round the corners of the pegs, and I will also cut the rhombi down to triangles so that the pieces can be combined in more ways.

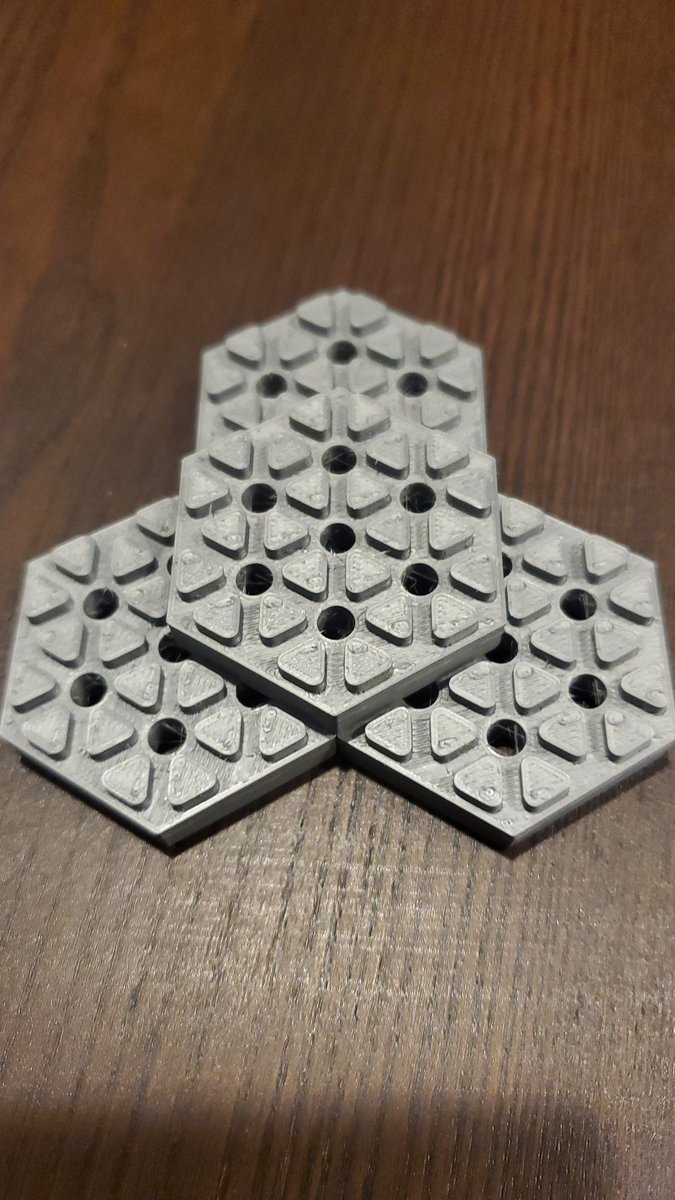

After a few attempts, I finally have a version that works really well. Will attempt to make a whole bunch of them and see how they work in groups, but at least they pass the initial tests!

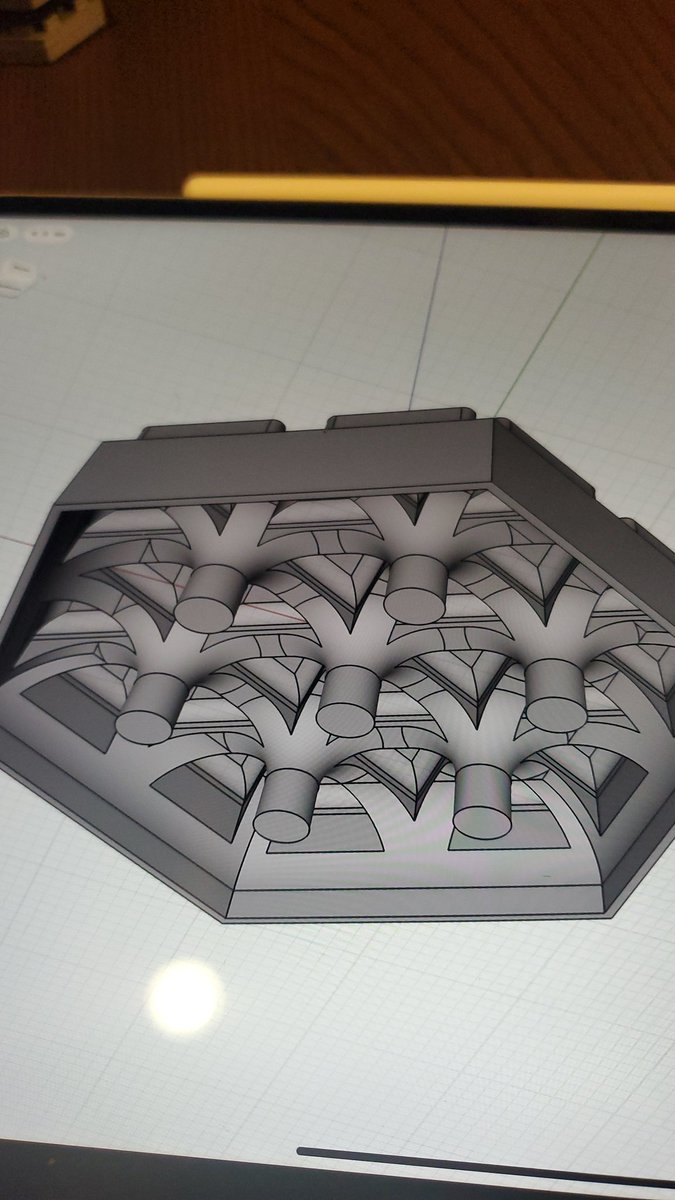

For the record, I made 2 versions that failed. They both had the columns too narrow, and the 3d printer messed them up no matter how hard I tried. First 2 photos are the one, and last 2 photos are the other.

This is the thickness of columns it took for the prusa to comfortably print them (and by comfortably I mean doing the first half at 50% speed. Haven't tried full speed from the start yet though)

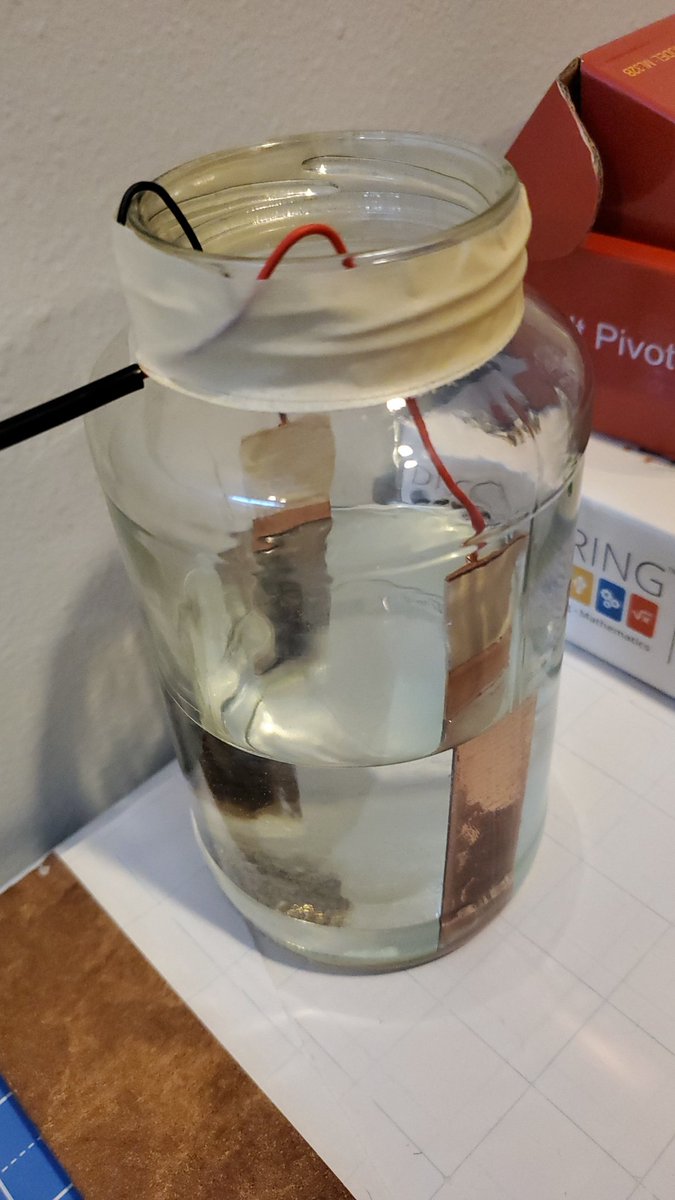

OK, after letting it load up on copper, I replaced the negative pole with conductive filament. About 1h40 later, it's looking VERY promising! The filament, normally black, is forming a decidedly copper-looking surface. I wonder what happens if I leave it to run overnight...

The idea is to print a circuit with multimaterial combo of conductive and nonconductive PLA. Then electroplating such that the conductive filament surface forms a copper layer on top. This turns the weakly conductive filament into proper copper traces. Basically a 3d printed PCB.

Though I came up with the idea myself, there seems to be prior work, at least from 2018, but this is good news! Means it might just work. https://www.sciencedirect.com/science/article/abs/pii/S2214860417305353

If the results are any good, I can imagine a delta-style printer printing straight into a container that can be then flooded with electrolyte for electroplating, and then draining the electrolyte for the print to dry. Maybe I could even try 3d circuits!

Or even 3d printing a motor in place. I gotta say I'm going down the whole 3d printer printing 3d printer rabbit hole quite deep, but it's so much fun I can't stop.

Read on Twitter

Read on Twitter