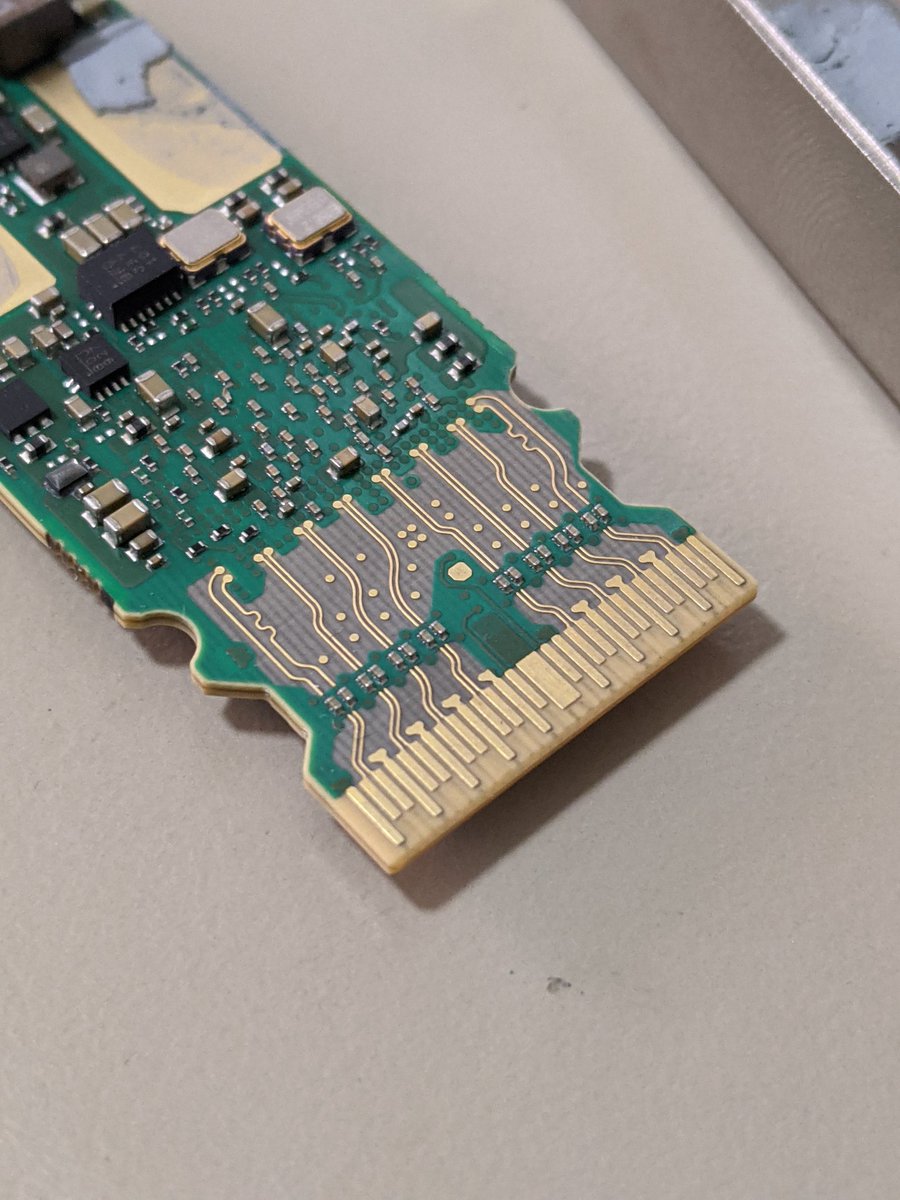

Engineering: "Make sure to not put solder mask on top of the high speed 56Gbps differential traces to reduce dielectric losses"

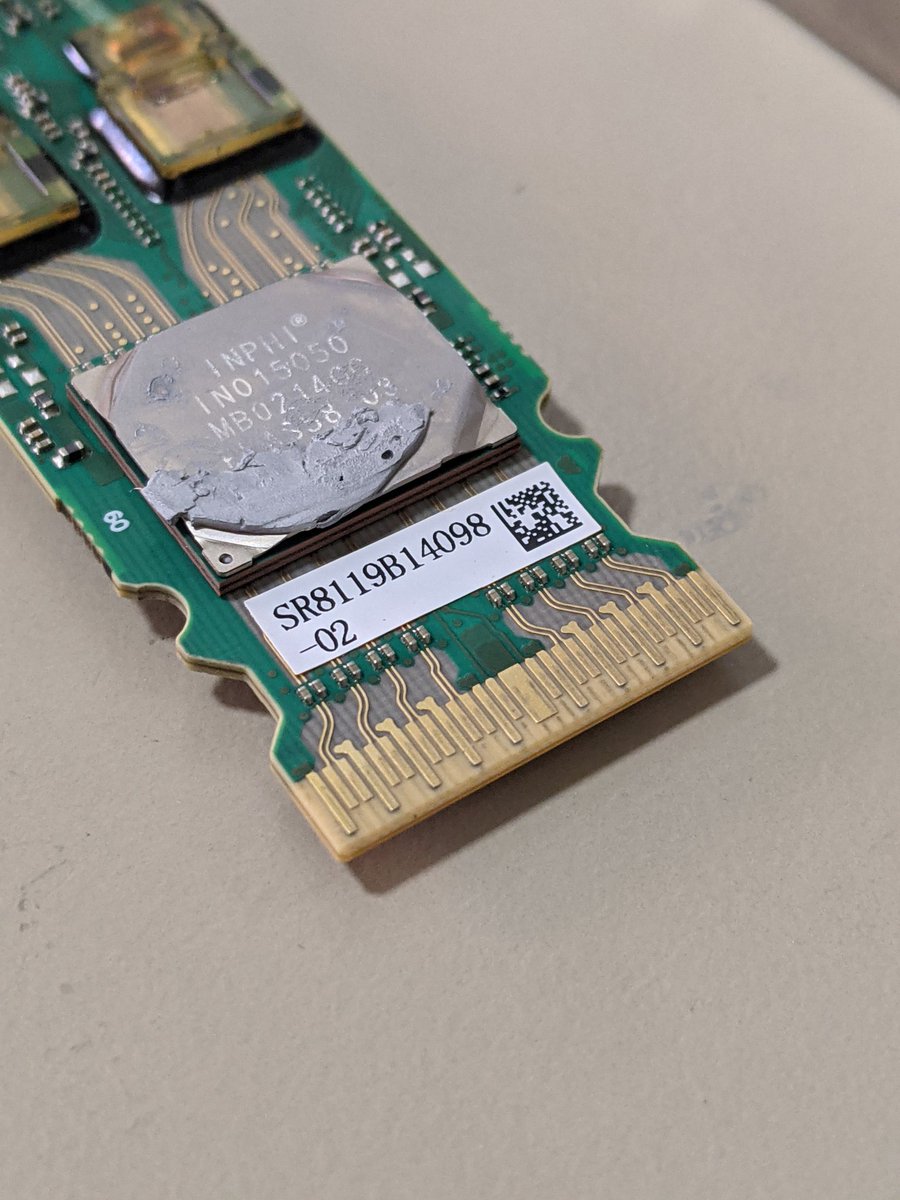

Manufacturing: "lol, sticker"

Manufacturing: "lol, sticker"

My favorite manufacturing problem I was personally involved with is still the time I was working on an RF assembly about the size of a small suitcase, and as soon as we transferred the design to volume manufacturing, the screws suddenly started seizing.

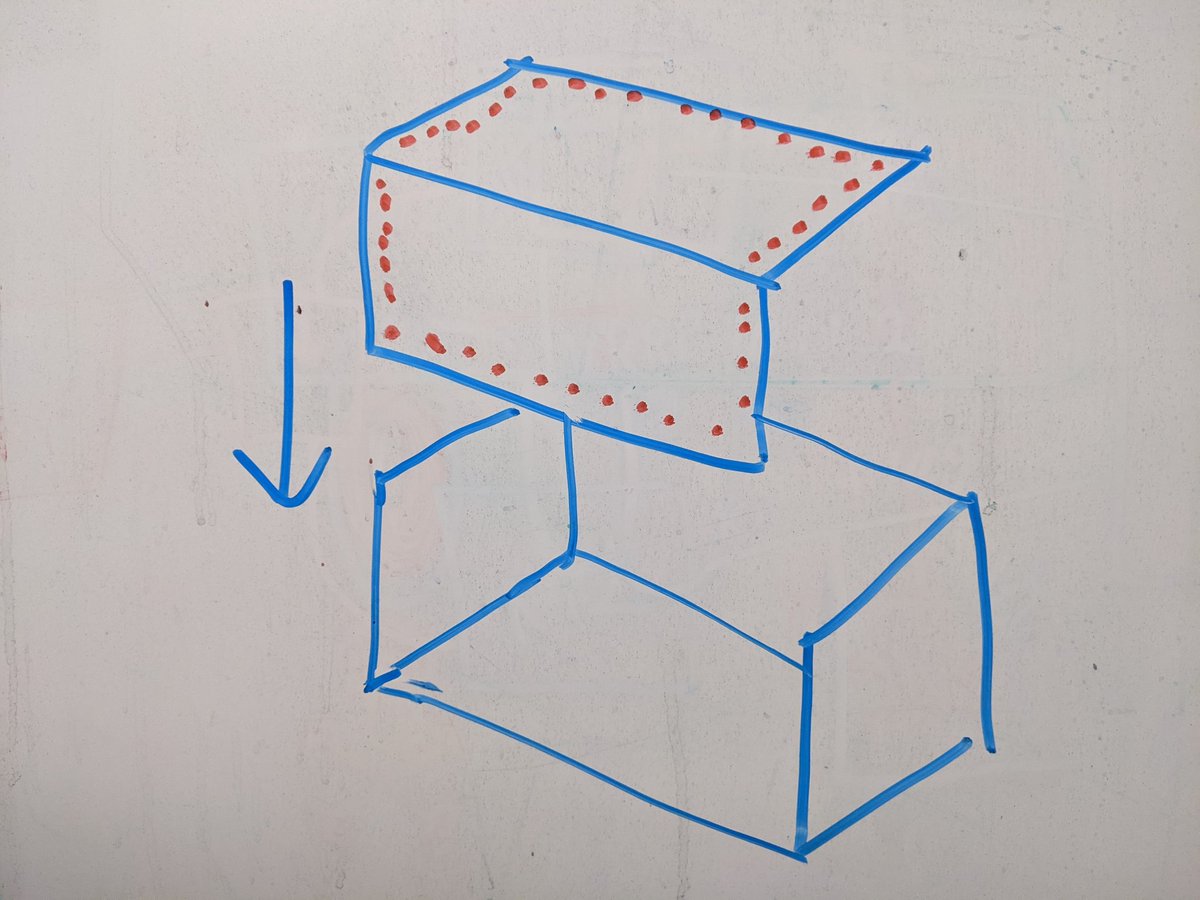

It was a welded aluminum box about 18" on the long end, with a removable lid held down by 43 stainless steel #6-32 screws threaded into helicoil inserts in the main enclosure body.

We built maybe two dozen of these assemblies between our engineering lab and pilot manufacturing, and they all worked great.

As soon as we moved them to the full scale volume facility, the screws started to seize in the helicoils.

As soon as we moved them to the full scale volume facility, the screws started to seize in the helicoils.

We had torque specs for these screws, that were being followed.

We checked calibration on the torque handles, and they were find. We took some of the screws off the volume line, and they worked fine in our lab.

What the heck.

We checked calibration on the torque handles, and they were find. We took some of the screws off the volume line, and they worked fine in our lab.

What the heck.

It was the gloves.

We didn't wear gloves in the engineering lab, and the pilot line was supposed to, but they didn't bother either.

They wore gloves in the volume manufacturing facility like they were supposed to.

We didn't wear gloves in the engineering lab, and the pilot line was supposed to, but they didn't bother either.

They wore gloves in the volume manufacturing facility like they were supposed to.

Here's the thing about stainless steel: it galls. If you screw a dry SS screw into a dry SS thread, there's the possibility for the two parts to cold weld together.

So why did this suddenly start happening once they were wearing gloves?

So why did this suddenly start happening once they were wearing gloves?

Because when we handled the stainless steel screws with our bare hands, oils from our skin would get on the threads and lubricate the screw just enough to prevent galling.

When we transferred it to a shop that actually kept the screws clean, galling started being a problem!

When we transferred it to a shop that actually kept the screws clean, galling started being a problem!

So we had two choices for how to fix this problem.

Either we ask the manufacturing techs to lick the screws before they install them, or spec out a thread locker to lube the threads to keep them from seizing during installation.

Manufacturing is hard.

Either we ask the manufacturing techs to lick the screws before they install them, or spec out a thread locker to lube the threads to keep them from seizing during installation.

Manufacturing is hard.

Read on Twitter

Read on Twitter