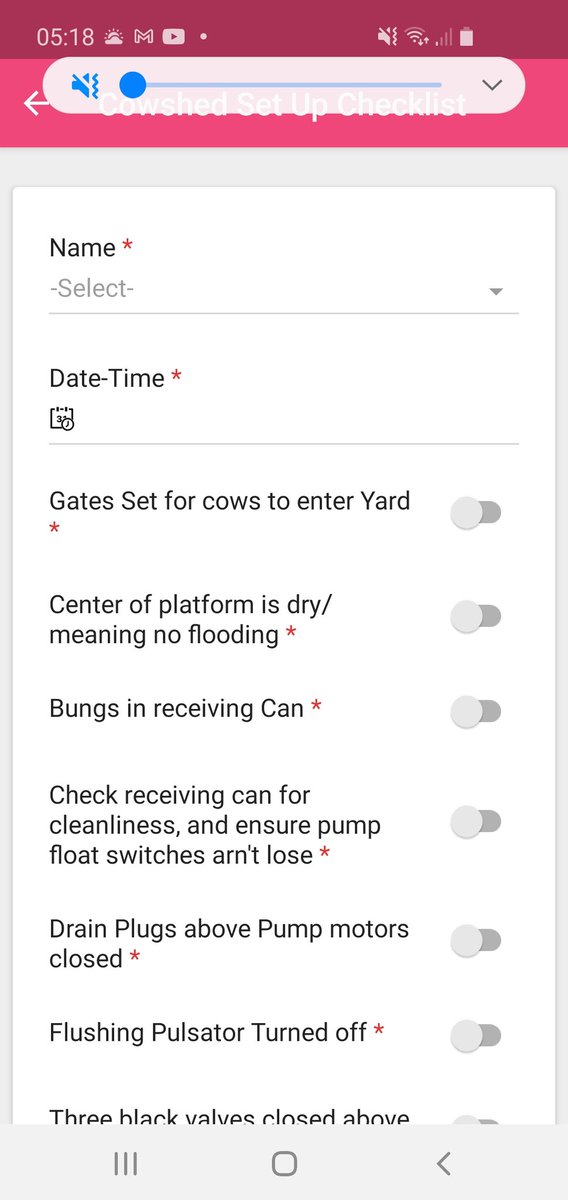

So will talk about some of tech in our cowshed this morning both hardware and software. First up are the app based checklists I created for setting the shed up for milking, the wash and for draining after the wash. Pictured is part of the set up checklist.

The idea behind it is to prevent screw ups. Got the idea from the program air crash investigation. So basically as staff set the shed up they tick the box saying they have done each task. The process of following the list means I get less stuff ups and people learn quicker

When the checklist is complete they hit submit and a copy gets sent to me. As part of the setup process they also take a photo of the water tank monitors and send them through to the farm chat group on whatsapp. This helps us spot when we might have water leaks early

As the cowshed is the central point on farm and all water flows from it to troughs, have just installed the new Gallagher flow monitors, so we can quickly isolate and turn off the affected section.

These units are fairly common now, its a Delavan hygenius control box, and basically it automatically controls the wash adding detergent, doing rinses etc. But for a brief period in 1998 this was the only one in New Zealand.

But like all tech it can help with time savings, but you need people on farm who can problem solve on those occassions where it doesn't play ball.

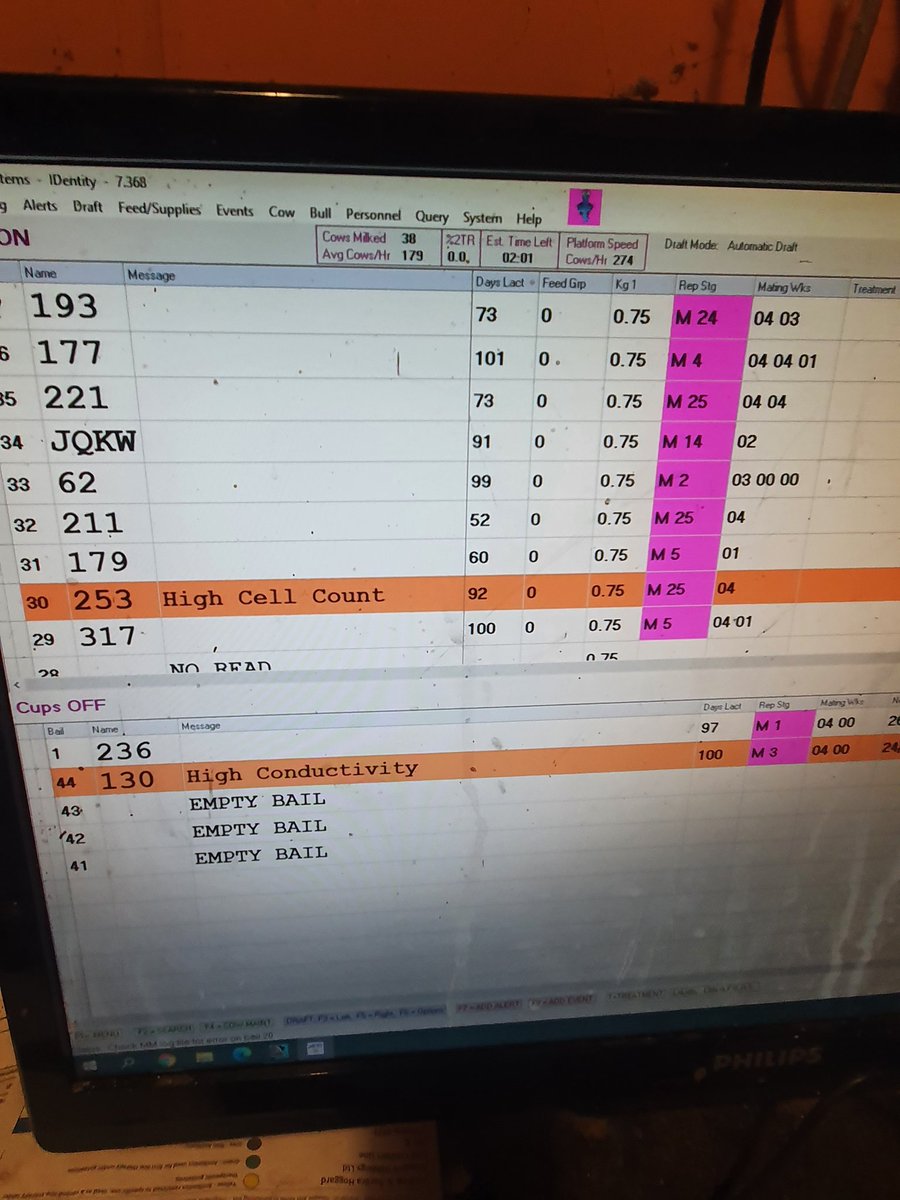

The main bit of kit we have in the shed is what at the time was the "dairy automation limited" system they have since been brought out by LIC. So the screen obviously display who is on the platform, they get read with an EID reader coming onto platform.

The screen will display any alerts on cows plus various usefull stats. You can enter events such as heats here, or enter drafts. Whilst being milked the milk goes through this little black box, and I get a protein, fat, litres, and somatic cell count reading for that cow

Then we have automatic cup removers which take cups off when is done, and auto teatspray in the exit race. So just one person required for cupping, the other person is getting cows in or cleaning.

This is a new little gizmo, my refrigeration service guy is a bit of an inventor and he knows I like being a Guinea pig. Basically what happens here is when the vat inflow handle gets opened and connects with that little cylinder thing it automatically starts the refrigeration.

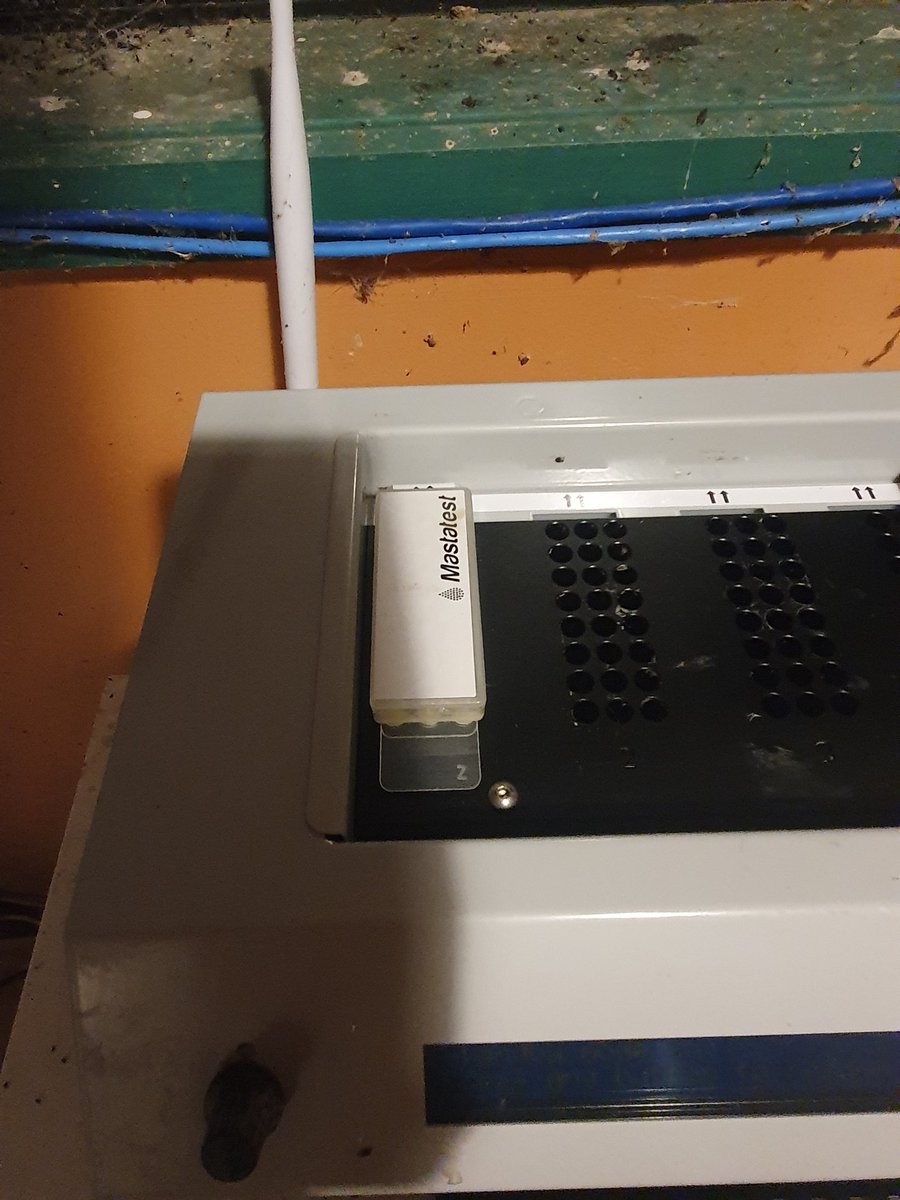

Finally another new bit of kit is the mastatest unit, basically you put a milk sample in a special little cartridge. Enter cow number and affected quarter. Put cartridge in machine it cultures it for 21 hours, there is a camera at the bottom which sends photo somewhere??

And I get an email back telling me what bug she has and best antibiotic to use, or whether its untreatable. Given where things are heading in terms of concerns around antimicrobial resistance a wise investment i think.

So for those that are interested that sample came back as strep uberis with coliform, and recomendation is we treat with albiotic.

One other thing we have is the batt latch. At a certain time the handle releases and the cows can start walking to shed. Again just another thing to try and save time.

Live action shot

Read on Twitter

Read on Twitter