Today, we are going to talk about engineered sheet materials; plywood, MDF and the like. Nothing to do with defence or politics :)

1/

1/

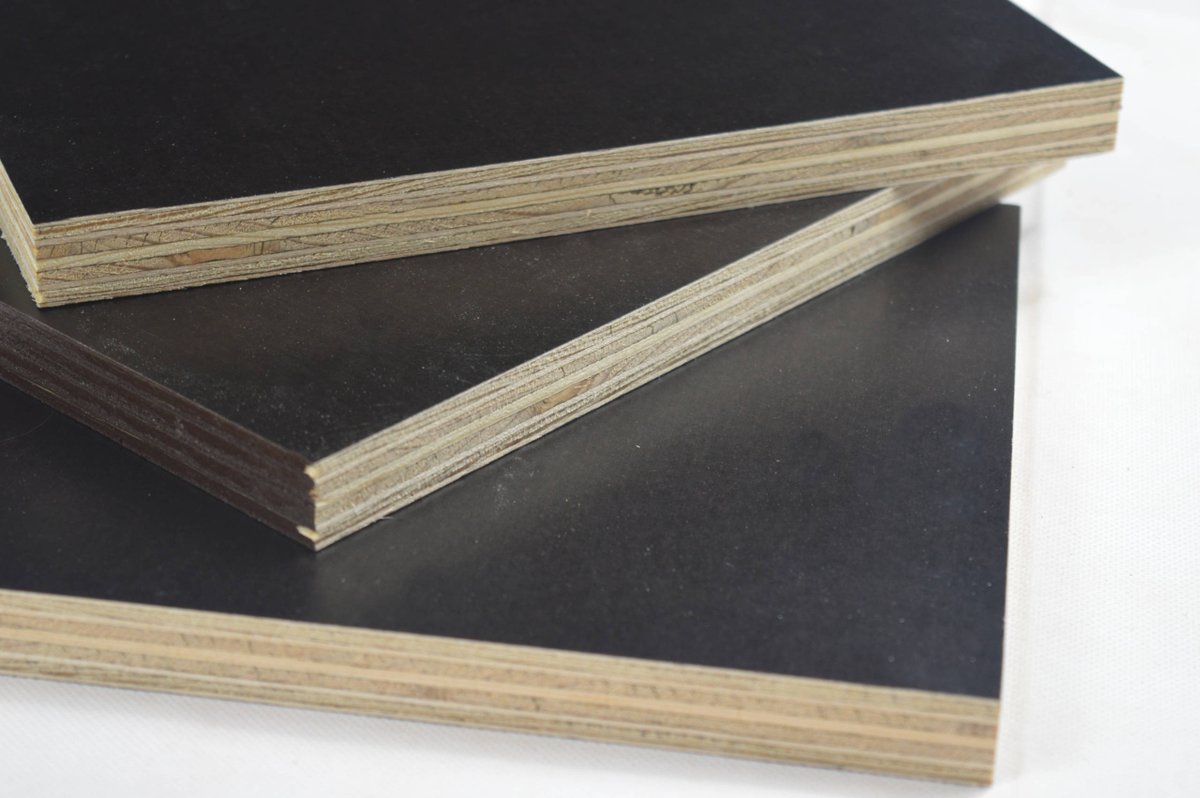

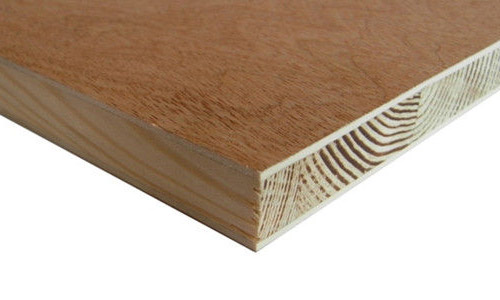

Plywood construction takes thin sheets of moistened timber and laminates them cross grain using a high strength glue. Cross graining minimises warping and edge grain splitting.

2/

2/

Different species and glue are used to create different types of plywood. Furniture products and for indoor use, marine ply for weather resistance, sheathing ply for construction, and of course, different sizes and thicknesses

3/ https://hanson-plywood.co.uk/product-category/plywood/

3/ https://hanson-plywood.co.uk/product-category/plywood/

A number of different standards are used for plywood, BS EN 314 for bonding quality for example

/4

https://shop.bsigroup.com/ProductDetail/?pid=000000000030083887

/4

https://shop.bsigroup.com/ProductDetail/?pid=000000000030083887

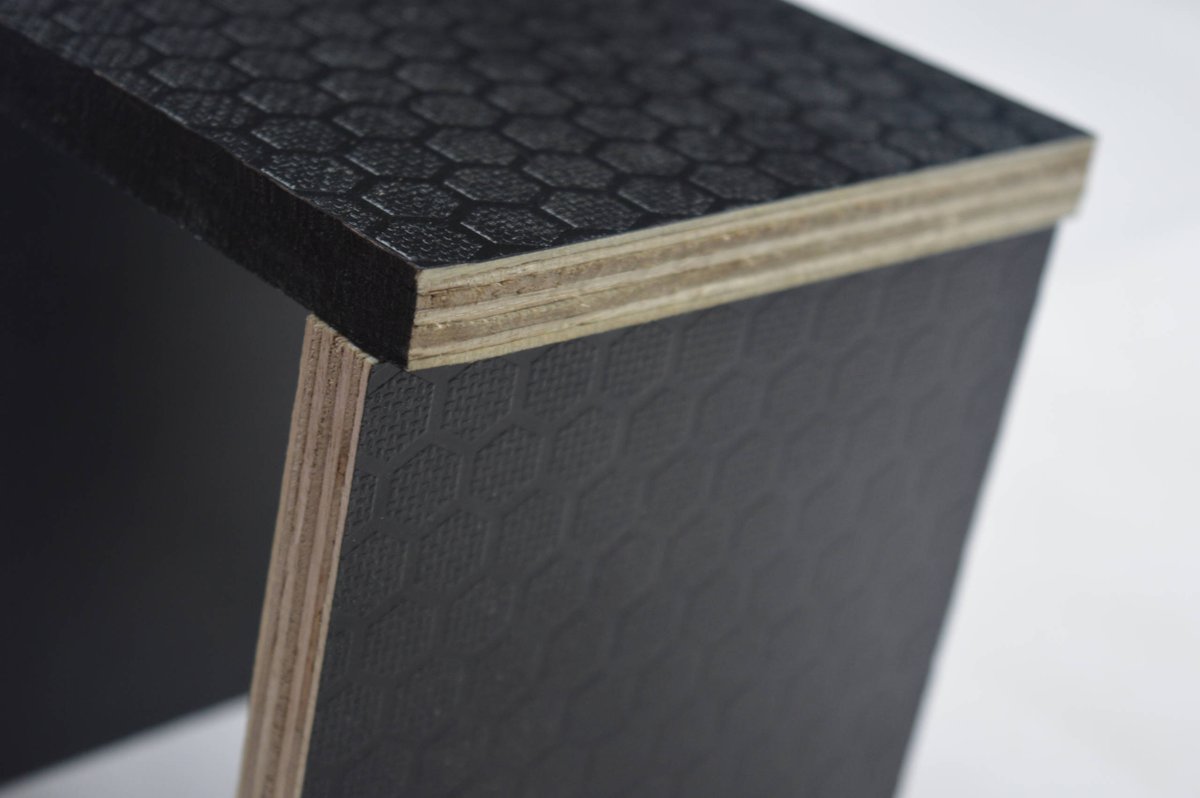

Decorative veneers can also be applied during manufacture, and there are many specialist types; for water jet/laser cutting, flexible, fire retardant, with non-slip or smooth surfaces and many more

/5

/5

Blockboard is a type of plywood that uses veneer for the front and rear surfaces but the core is solid timber.

/6

/6

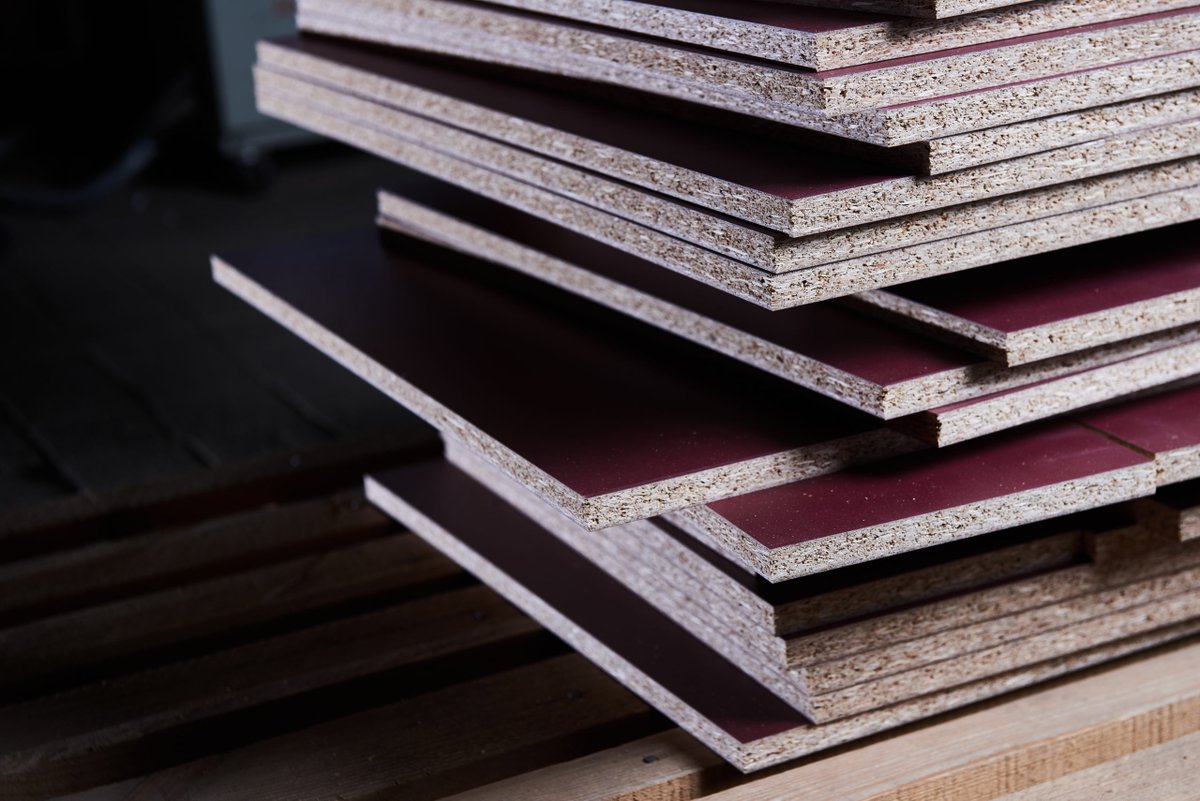

Particle board (chipboard) is a low-density material that makes use of waste wood flakes, mixed with glue and highly compressed. Like plywood and blockboard, it can be faced with a variety of materials, machined to create profiles and available in various grades.

/8

/8

Chipboard generally has very little moisture resistance but it is strong, cheap and very tolerant to the drying effects of central heating, when covered, it is commonly used in furniture and kitchen units.

/9

/9

Oriented Strand Board (or OSB) is a construction grade material commonly used for site hoarding, roofing and form work.

/10

/10

Hardboard (sometimes called Masonite) is a high-density fibreboard but only available in thin sheets and can be coated or perforated to create pegboards. It is also used to create smooth surfaces for flooring. Pinboard uses waste paper

/12

/12

Stokbord is not strictly a timber product, it uses recycled plastics, but is commonly used as a timber board replacement in the utility and farming sectors.

/13 https://www.centriforce.com/stokbord/

/13 https://www.centriforce.com/stokbord/

Medium Density Fibreboard (MDF) uses pressure treated wood fibres and bonding agents to create a stable, strong and easy to machine product. It is much denser than chipboard and cheaper than plywood. The core and face tend to have a slightly different density.

/14

/14

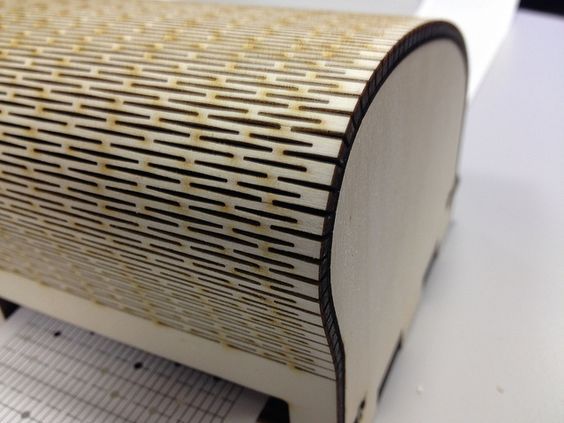

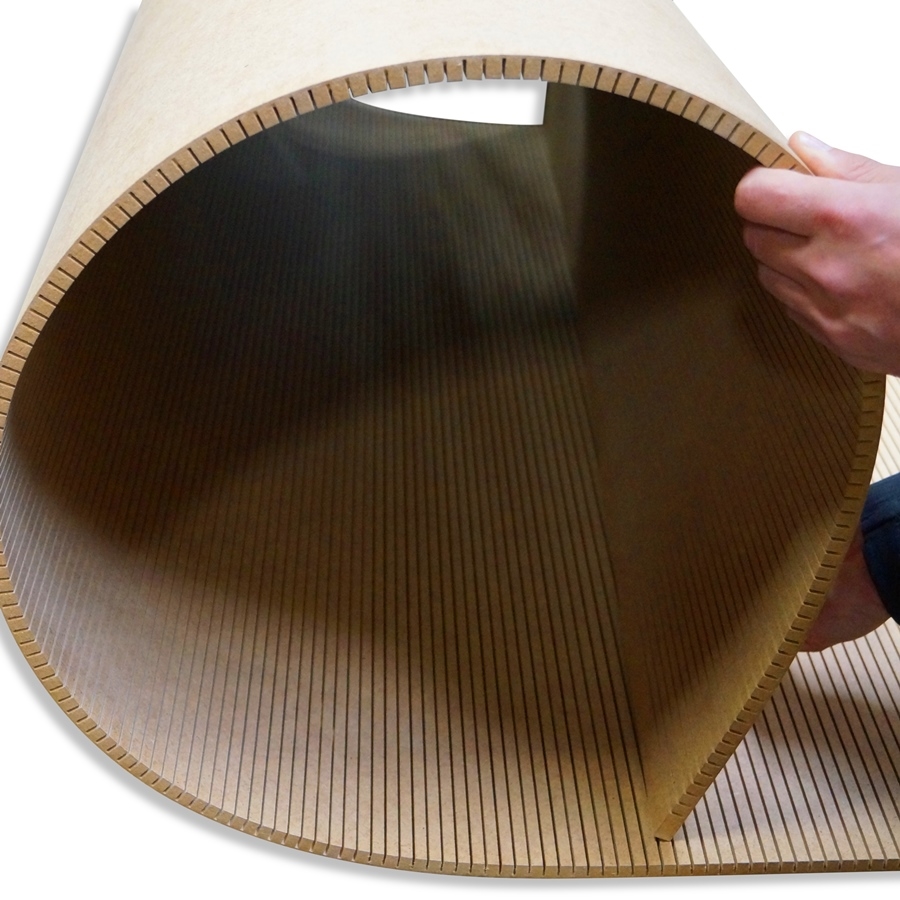

Lightweight, veneered, fire-resistant, painted and high gloss coatings are also available (the latter used for modern kitchen doors and panels). It is even available in pre-kerf cut sheets for easy bending.

/15

/15

MDF is even available in a self-coloured version called Valchormat

/16

/16

Hope this was useful, it only scratches the surface of the main types, there are many more variations.

/END

/END

Read on Twitter

Read on Twitter