OK so here's a teardown that isn't really a teardown, and a fun science experiment.

I got a UV disinfecting wand!

I got a UV disinfecting wand!

So this is a battery powered light that's designed to kill viruses, germs, and bacteria. Cool. How's that work?

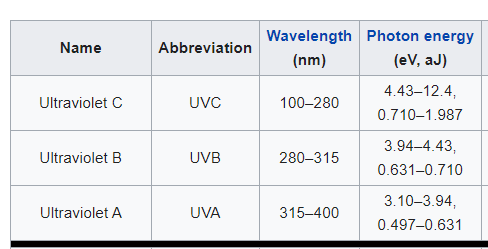

So ultraviolet light comes in three bands, from longest to shortest wavelengths: A, B, and C.

UVA is backlights, and is harmless (mostly)

UVB is the kind of light that gives you sunburns and skin cancer. It's partially filtered out by the ozone layer, thankfully.

UVA is backlights, and is harmless (mostly)

UVB is the kind of light that gives you sunburns and skin cancer. It's partially filtered out by the ozone layer, thankfully.

which is part of why the hole in the ozone layer is such a bad thing. Less ozone in the atmosphere means more of the UVB light makes it down to ground level, and everyone is at greater risk of skin cancer.

But UVC is the interesting one here. It's normally almost fully blocked by the atmosphere, so it effectively doesn't exist on the ground.

And that's good, because it destroys nucleic acids, like "DNA" and "RNA".

And you're made of those.

And that's good, because it destroys nucleic acids, like "DNA" and "RNA".

And you're made of those.

This works by causing a reaction between thymine molecules (that's the T in G-C-A-T bases of DNA), which causes them to link together. This makes them unable to be replicated or transcribed properly.

And there are repair mechanisms to fix this, but they aren't perfect. too many damaged based and the cell will be incorrectly repaired or fail to replicate completely, killing the cell or possibly turning it cancerous.

which is scary and terrible... but also useful!

See, viruses and bacteria and germs and such all have DNA or RNA... what if we shine UVC light on them?

Well, it'll kill them. And the neat thing is that this isn't based on poisons or chemicals or mechanical cleaning: it's light.

See, viruses and bacteria and germs and such all have DNA or RNA... what if we shine UVC light on them?

Well, it'll kill them. And the neat thing is that this isn't based on poisons or chemicals or mechanical cleaning: it's light.

so you don't have to worry about things like those poisons hanging around and affecting you or other animals, or the chemicals forming residues, or ensuring you clean every corner... it's just light. Light that will damage DNA & RNA.

So obviously this is very useful and it's a great idea to build it into a portable sterilization system.

And you'd think the only issue is that it's pretty good at sterilizing YOU, too... but no, that's not the problem here.

And you'd think the only issue is that it's pretty good at sterilizing YOU, too... but no, that's not the problem here.

See the big issue with these right now is that there have been a TON of them rushed to market, given the whole everything going on right now.

And you know what's way cheaper and easier to make than a UVC sterilization system?

A fake one!

And you know what's way cheaper and easier to make than a UVC sterilization system?

A fake one!

So there's tons of these products on ebay and aliexpress and amazon which are marketed as UV Sterilization lamps/wands/whatever, but actually don't put out any UVC light.

They put out UVA (so they're blacklights) or just blue light (so they're flashlights)

They put out UVA (so they're blacklights) or just blue light (so they're flashlights)

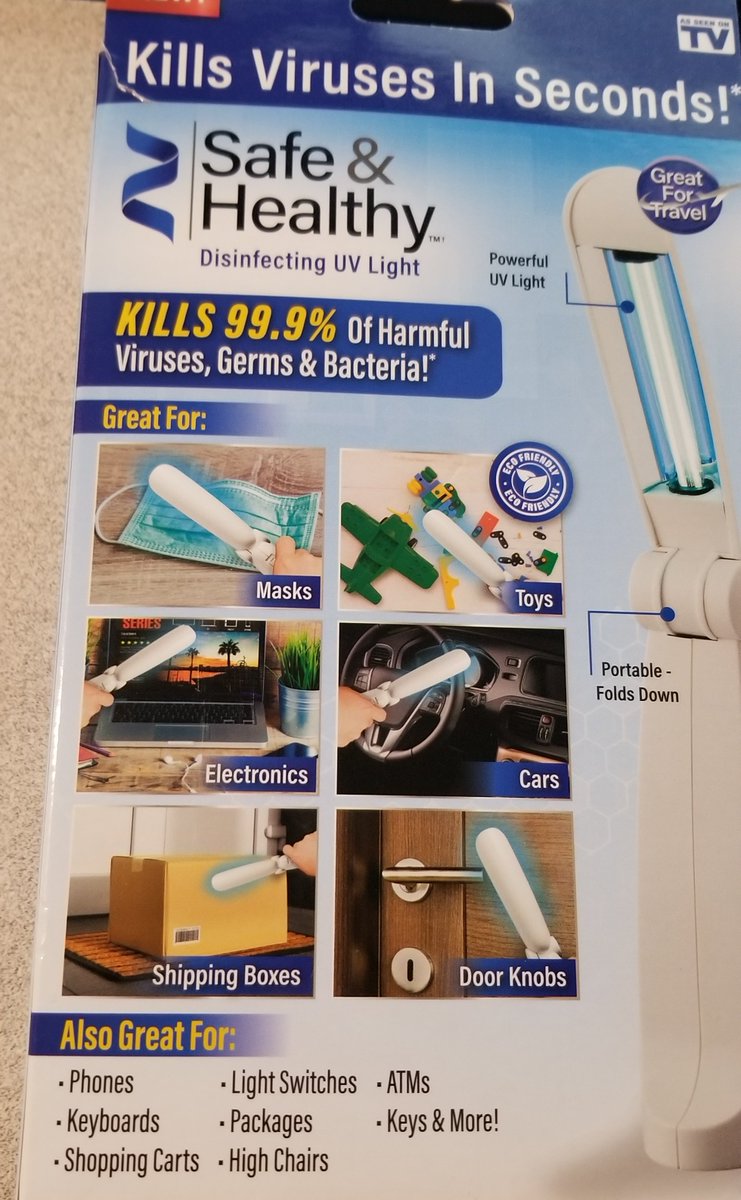

But looking at the box we can see this one seems to use fluorescent tubes. That's a good sign:

most real UVC systems will be fluorescent. There are UVC LEDs, but they're not cheap and they have to use special housings or the UVC they emit will destroy them.

most real UVC systems will be fluorescent. There are UVC LEDs, but they're not cheap and they have to use special housings or the UVC they emit will destroy them.

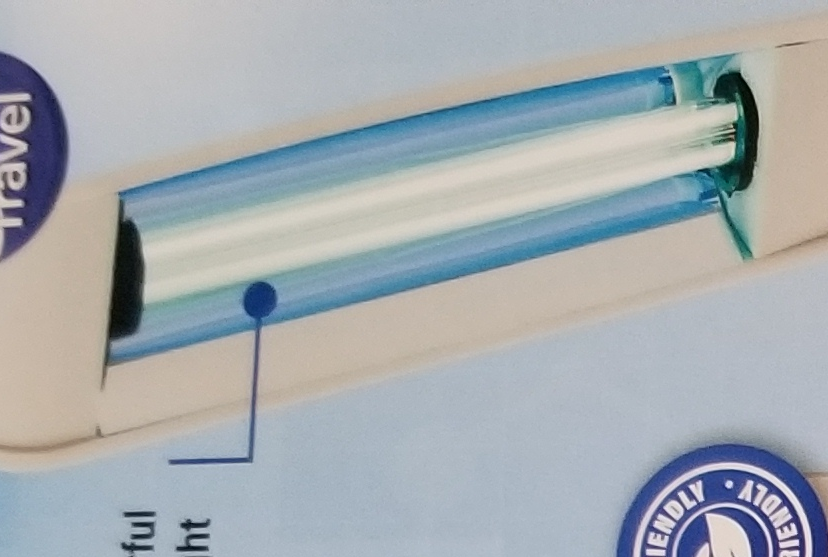

Do not look at light or use on skin, it says.

That's good advice, especially the first part.

You can get UVC damage to your eyes: it's basically a sunburn on your eyes, and that's not fun.

That's good advice, especially the first part.

You can get UVC damage to your eyes: it's basically a sunburn on your eyes, and that's not fun.

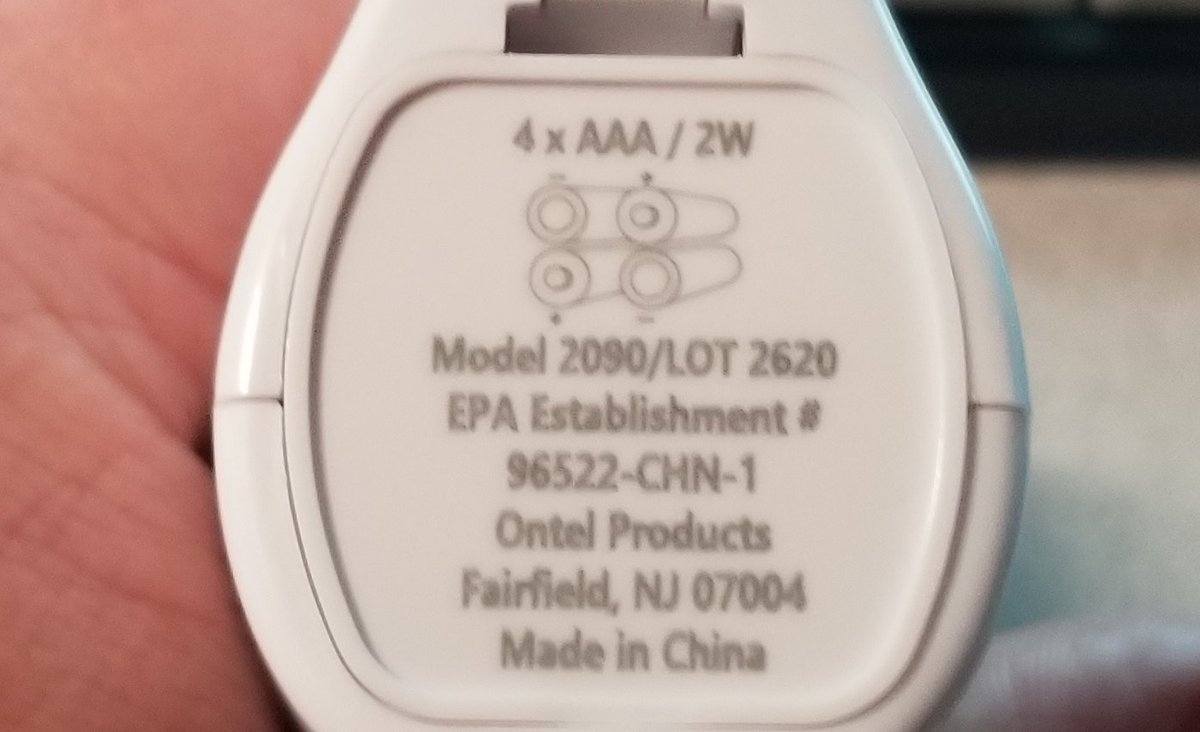

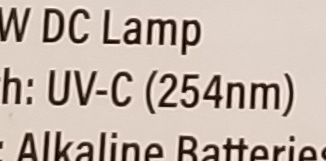

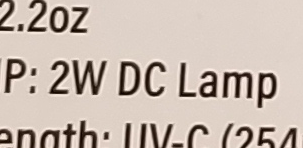

So this is the Ontel Products "Safe & Healthy" Model 2090. It takes 4 AAA batteries, which aren't included.

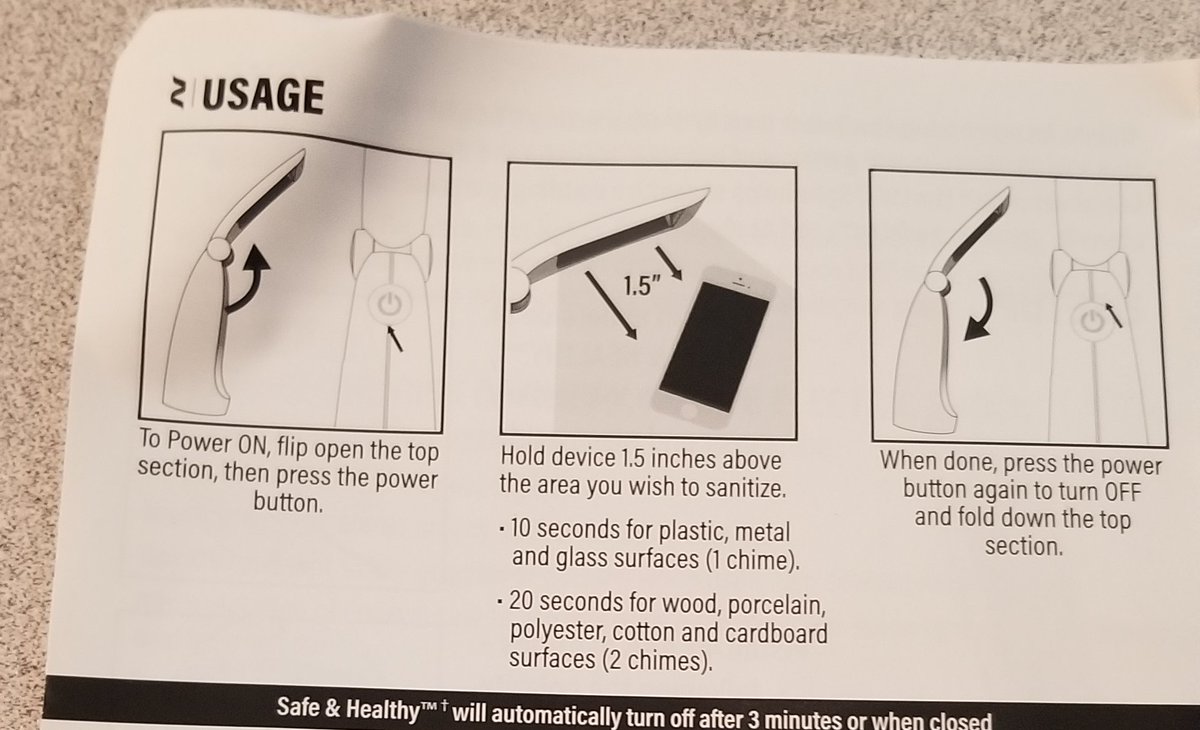

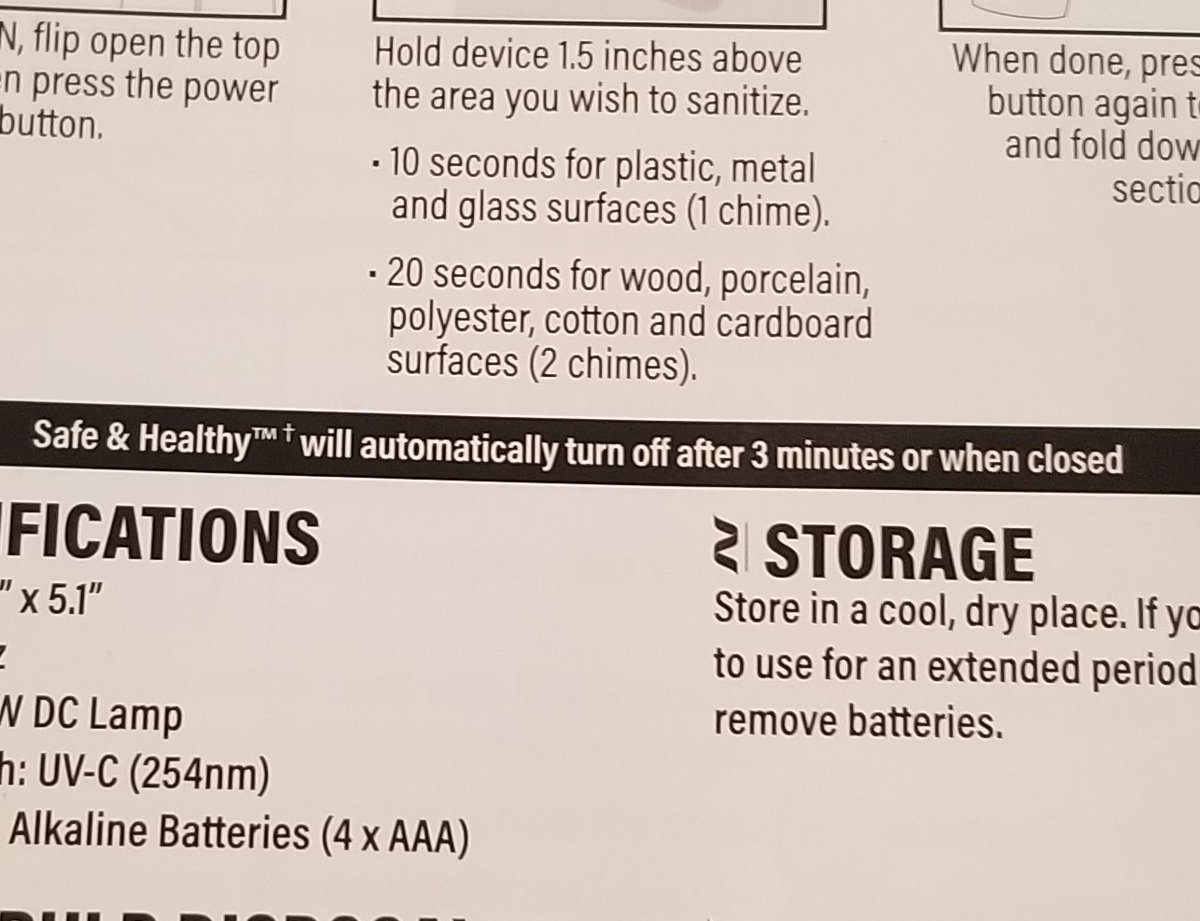

So you flip it on and push the button, then hold it above whatever you want to sanitize. It'll beep every 10 seconds, and they suggest 10 seconds for plastic/metal/glass, and 20 seconds for wood/porcelain/polyester/cotton/cardboard.

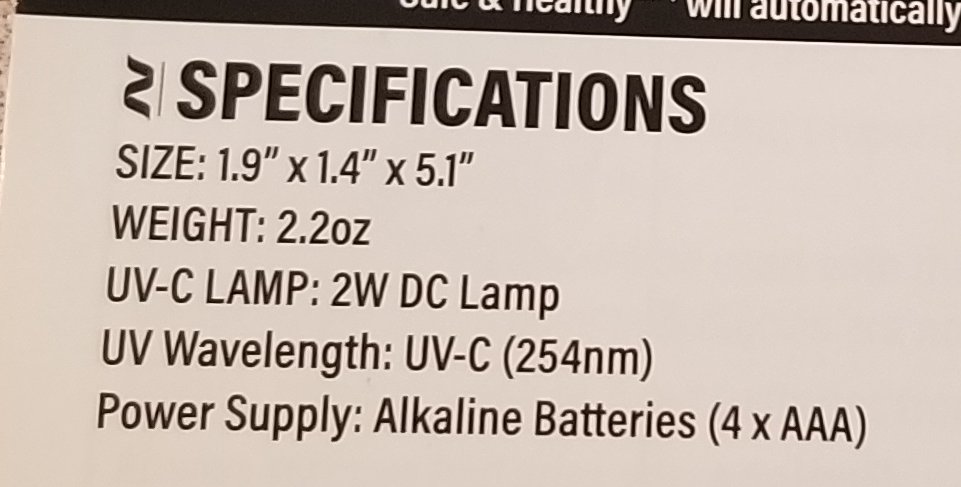

And they say here that it's a 2 watt DC lamp, supplying 254 nanometer UV-C light.

That suggests it's a mercury-vapor lamp.

That suggests it's a mercury-vapor lamp.

So how are we gonna test this?

Get two petri dishes, get some bacteria in them, then expose one and not the other, then wait to see how much the bacteria grows?

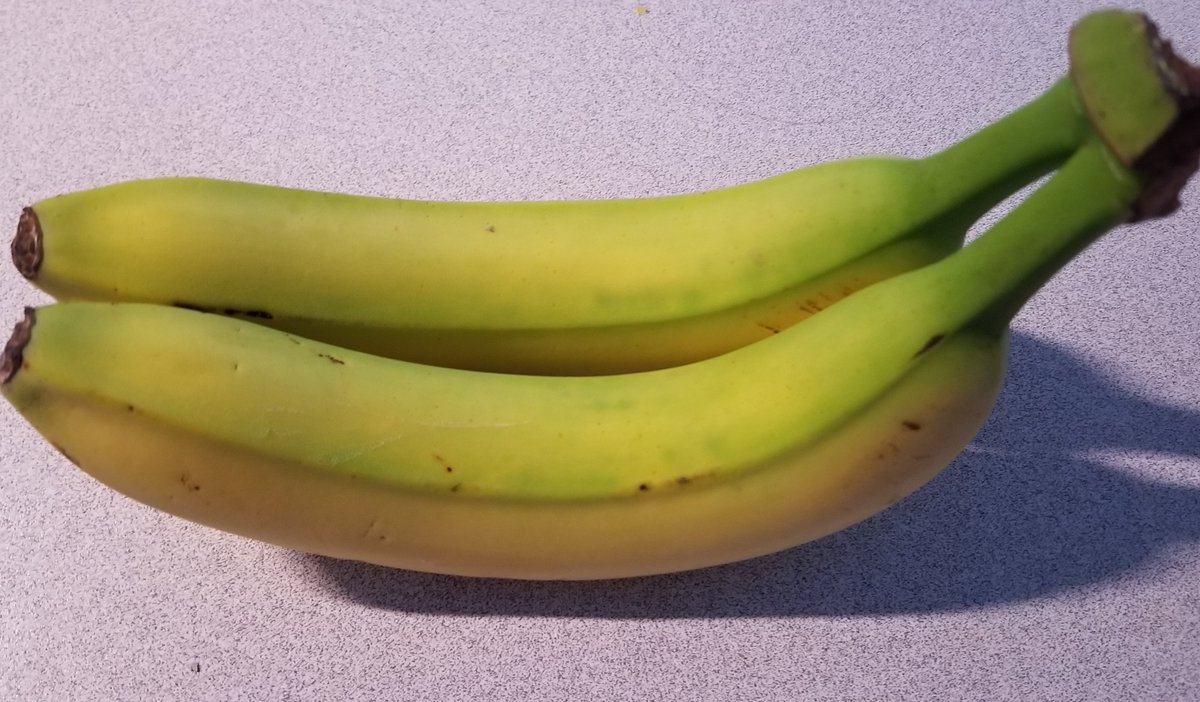

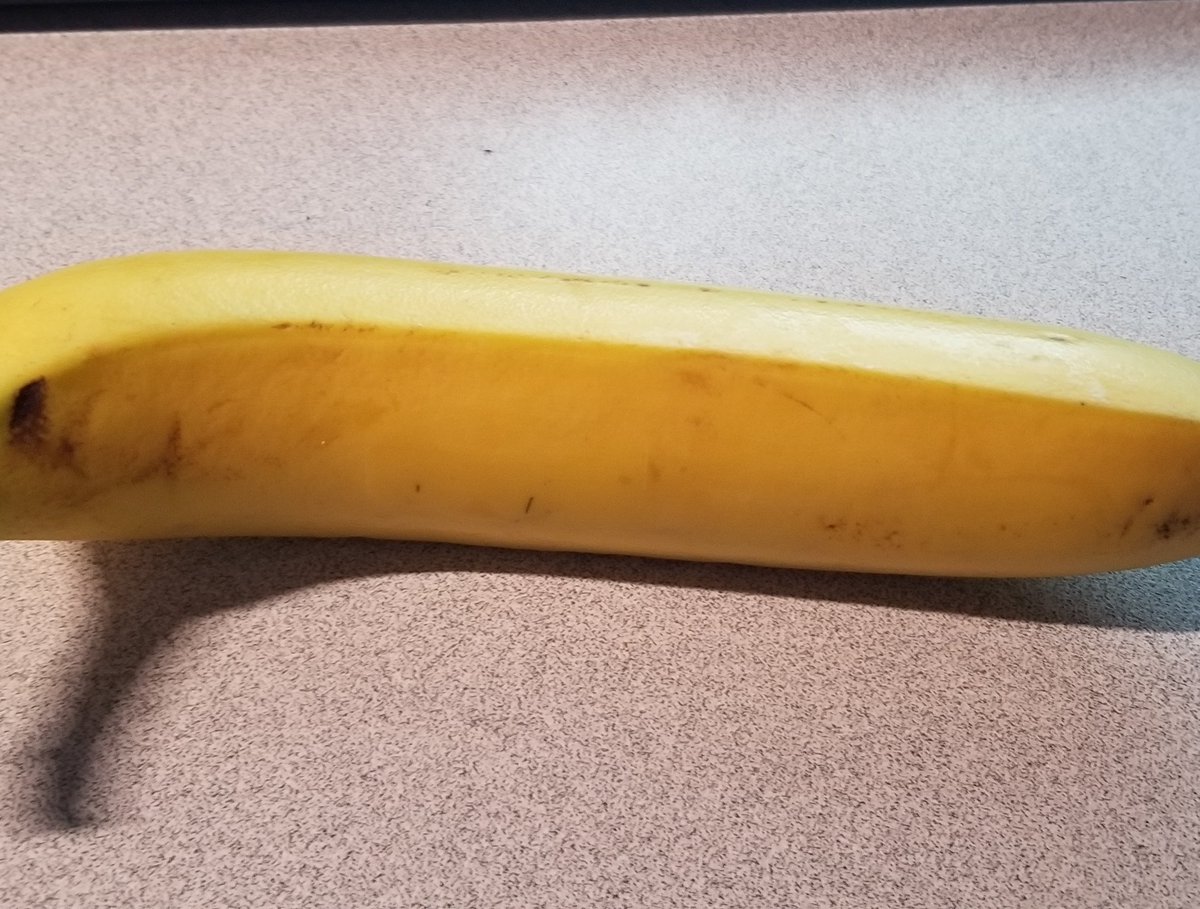

Nah, that sounds hard. I don't have a lab here. But what I do have... is bananas.

Get two petri dishes, get some bacteria in them, then expose one and not the other, then wait to see how much the bacteria grows?

Nah, that sounds hard. I don't have a lab here. But what I do have... is bananas.

So all I need is some green bananas and electrical tape. I'm gonna stick the tape on the bananas, covering up some of the green skin, then I'll expose a banana to UV light.

The other banana is the control banana, and I'll put a flashlight on it.

The other banana is the control banana, and I'll put a flashlight on it.

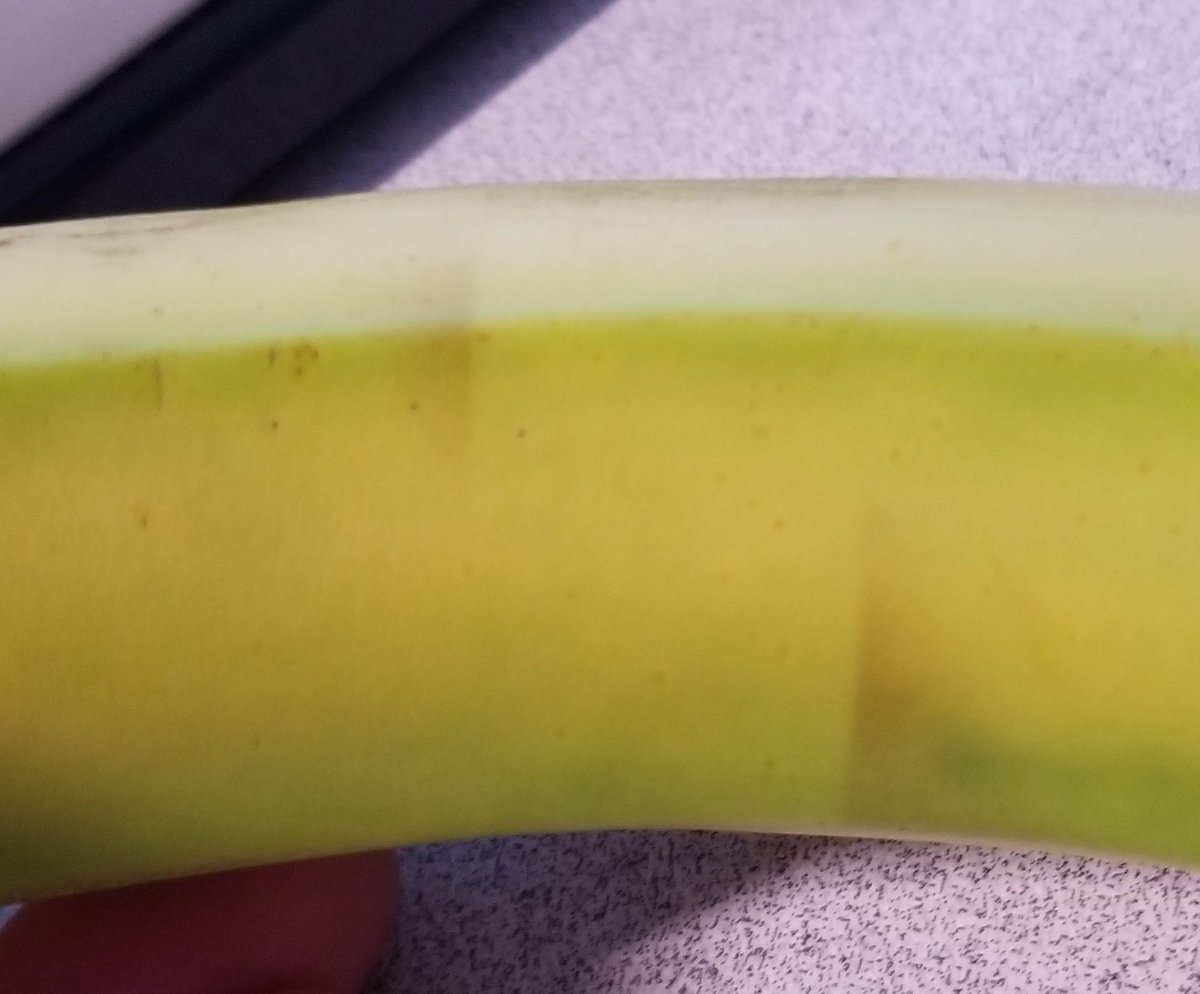

And after 15 minutes on the flashlight, the banana looks like this after removing the eletrical tape.

Pretty much the same.

Pretty much the same.

And after 15 minutes on the UV-C light, the other banana looks like this... pretty much the same.

You can spot a little bit of faint difference in color if you look very closely, but it's barely there.

But we need to wait.

You can spot a little bit of faint difference in color if you look very closely, but it's barely there.

But we need to wait.

Because later in the day (like 6-10 hours), the banana looks like this.

See how there's two brown patches on the banana, but they have a very sharp edge? that's where the electrical tape was.

See how there's two brown patches on the banana, but they have a very sharp edge? that's where the electrical tape was.

and about 24 hours later, it looks like this.

The brown spot has gotten a lot bigger, but it still has that very clear sharp edge where the electrical tape had covered up the banana skin.

The brown spot has gotten a lot bigger, but it still has that very clear sharp edge where the electrical tape had covered up the banana skin.

So we can conclude that this UV lamp actually is UVC producing, and not a scam. Great.

But what the heck is happening to the banana, and why did the lamp do this?

But what the heck is happening to the banana, and why did the lamp do this?

well, bananas are not dead when picked from the tree.

Their cells are still active, and still working.

and they're breaking down the starches and chlorophyll and turning it into sugars. This is why ripe bananas are sweeter than green bananas.

Their cells are still active, and still working.

and they're breaking down the starches and chlorophyll and turning it into sugars. This is why ripe bananas are sweeter than green bananas.

and what happened when UVC light was shined on part of the banana?

Well, those cells were damaged. the DNA of the banana broke down in those places, causing the ripening reaction to not work the same as in the rest of the banana.

Well, those cells were damaged. the DNA of the banana broke down in those places, causing the ripening reaction to not work the same as in the rest of the banana.

So, a fun fact about how bananas ripen:

They emit ethylene gas as they ripen, and here's the other fun fact:

ethylene gas causes bananas to ripen faster.

They emit ethylene gas as they ripen, and here's the other fun fact:

ethylene gas causes bananas to ripen faster.

the evolutionary reason for this seems to be that if the bananas make other nearby bananas ripen too, it'll cause all the bananas to be ripe at the same time, which makes a banana plant a more enticing meal for animals.

and of course the bananas are the fruit of the banana plant, they contain the seeds, they "want" animals to eat them and spread the seeds.

So the fun implication of this is that when you go to the store and they've got some green bananas and some nice ripe yellow bananas, the yellow bananas aren't just the green bananas later on.

And you can tell this if you get some green bananas at let them ripen!

And you can tell this if you get some green bananas at let them ripen!

but if you get a green banana and let it ripen, it tends to look more like this.

Some spots ripened faster and are now a little past ripe, and there's less evenness across a group of bananas.

Some spots ripened faster and are now a little past ripe, and there's less evenness across a group of bananas.

and that's because the store actually orders both ripe and unripe bananas, separately.

The ripe bananas were artificially ripened, and it wasn't just by leaving some bananas around and waiting.

The ripe bananas were artificially ripened, and it wasn't just by leaving some bananas around and waiting.

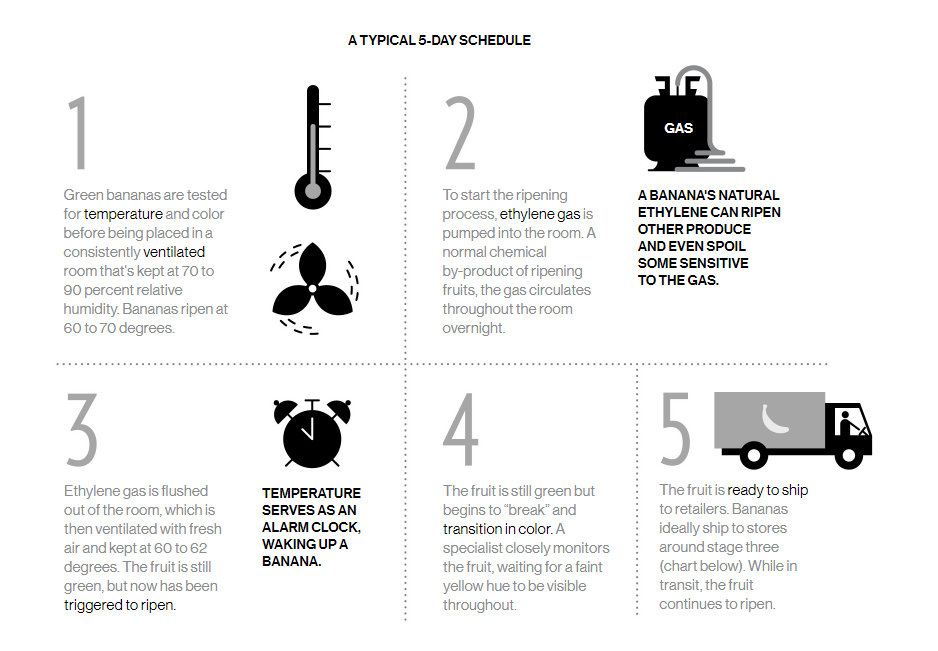

National Geographic has a little infographic about it.

Basically they're kept in a temperature controlled room which is flooded with ethylene gas, then they're kept at a specific temperature so they all ripen consistently and at the same time.

Basically they're kept in a temperature controlled room which is flooded with ethylene gas, then they're kept at a specific temperature so they all ripen consistently and at the same time.

that's from here: https://www.nationalgeographic.com/environment/urban-expeditions/food/food-journeys-graphic/

Basically this means you get bananas that are consistently ripe, they ripen faster, and they look better, because they ripened more evenly.

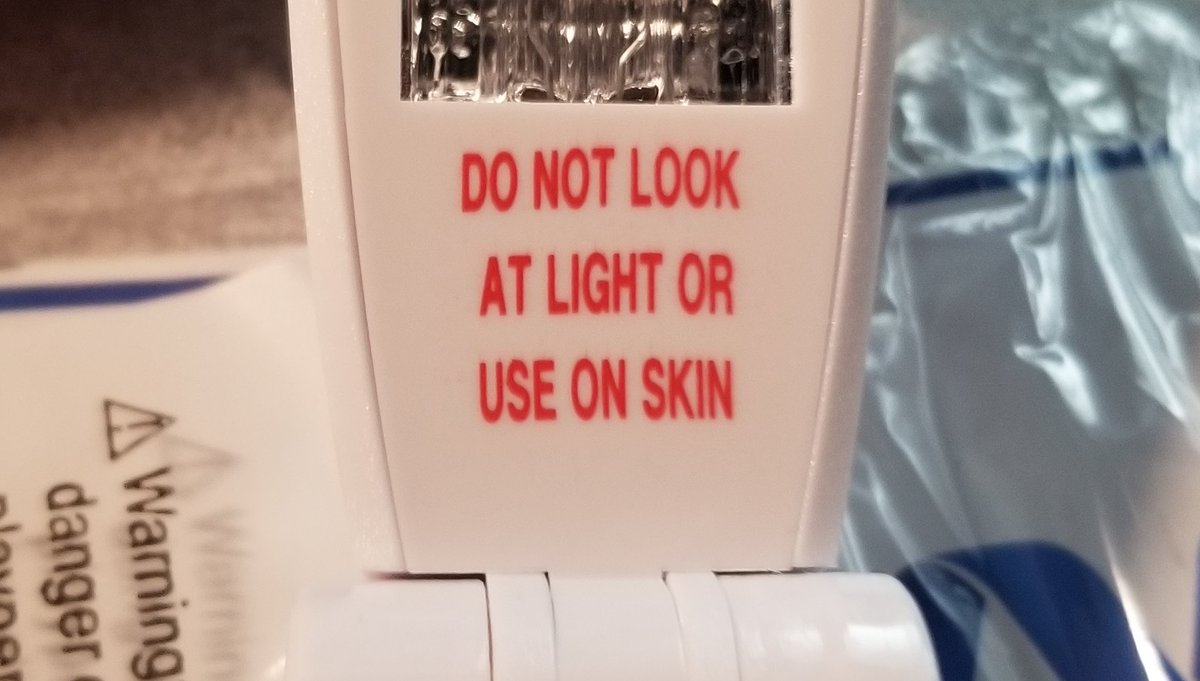

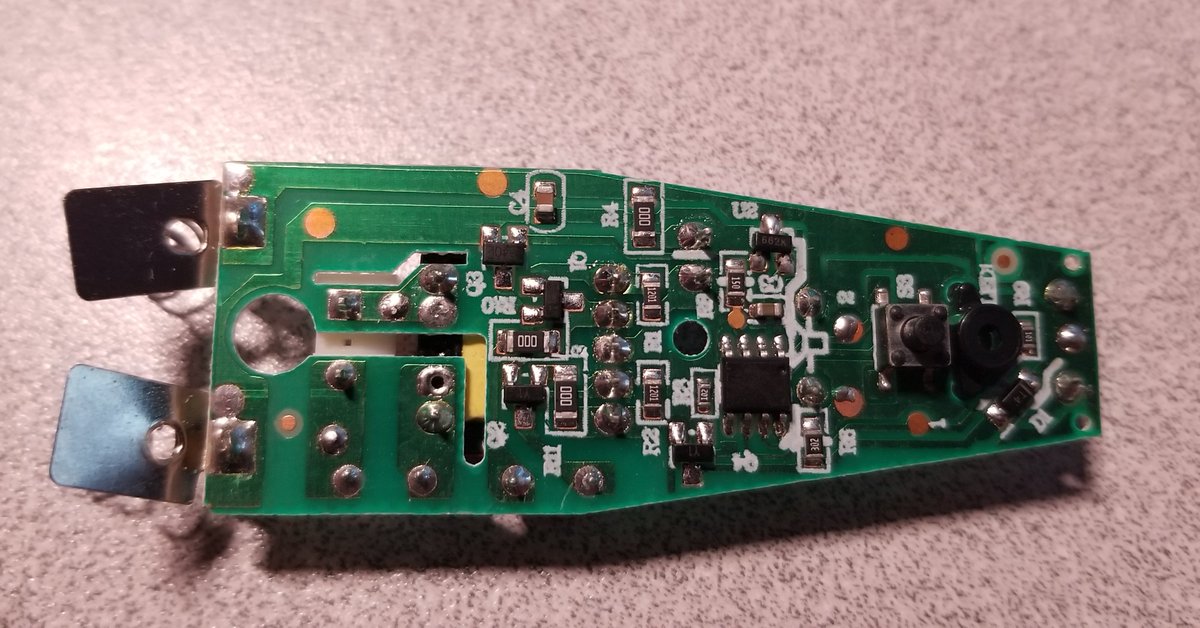

Anyway, after doing the BANANATEST, I took apart the UV wand.

There's just one PCB inside, and it's single-sided.

It's got a transformer on it (to generate the voltages needed for the UV light) and a little speaker. Plus a second button, which just turns off the light when closed

There's just one PCB inside, and it's single-sided.

It's got a transformer on it (to generate the voltages needed for the UV light) and a little speaker. Plus a second button, which just turns off the light when closed

The other site of the PCB.

There's a little anonymous 8-pin microcontroller which controls it, the other button, and an LED for the "I'm turned on" light.

There's a little anonymous 8-pin microcontroller which controls it, the other button, and an LED for the "I'm turned on" light.

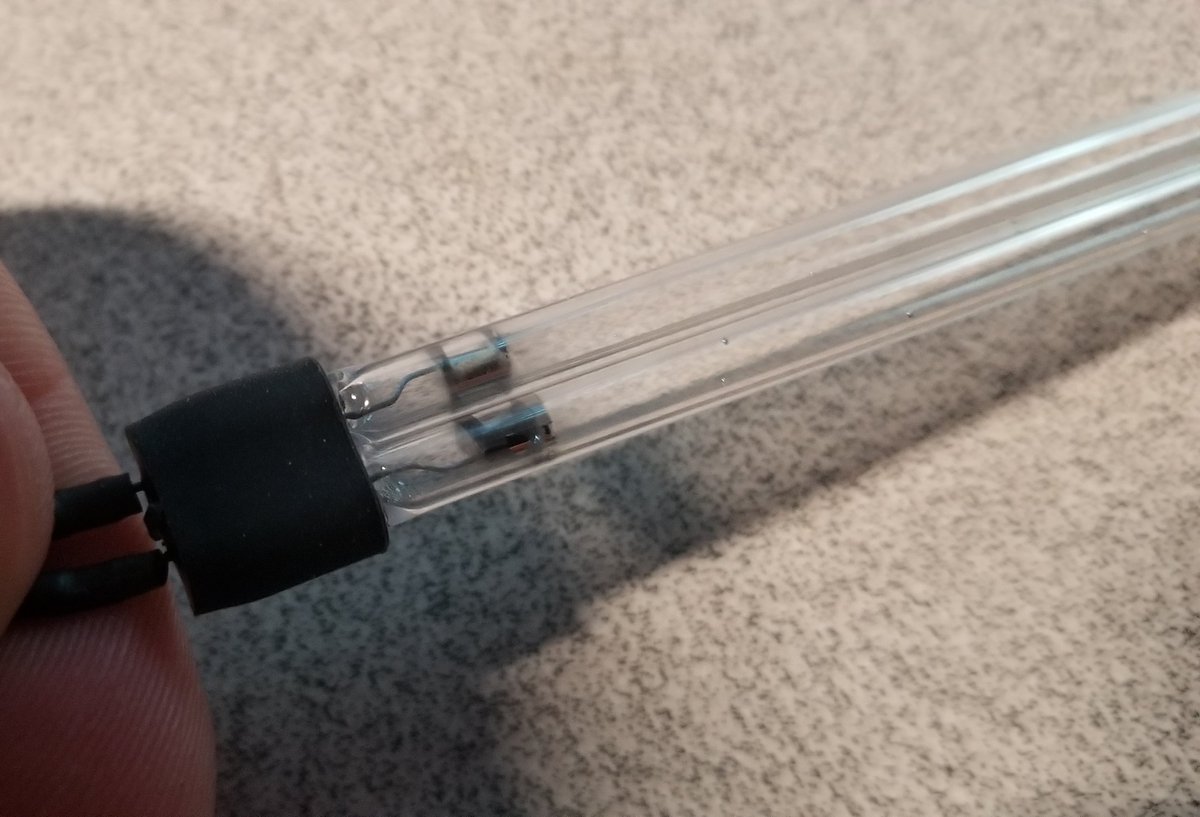

The tube itself.

There's no labels on it at all, which is annoying. It's also got mercury in it, so this is definitely a product you should be careful with. There's no protective class or plastic in front of the tubes when it's open, so they could be easily broken.

There's no labels on it at all, which is annoying. It's also got mercury in it, so this is definitely a product you should be careful with. There's no protective class or plastic in front of the tubes when it's open, so they could be easily broken.

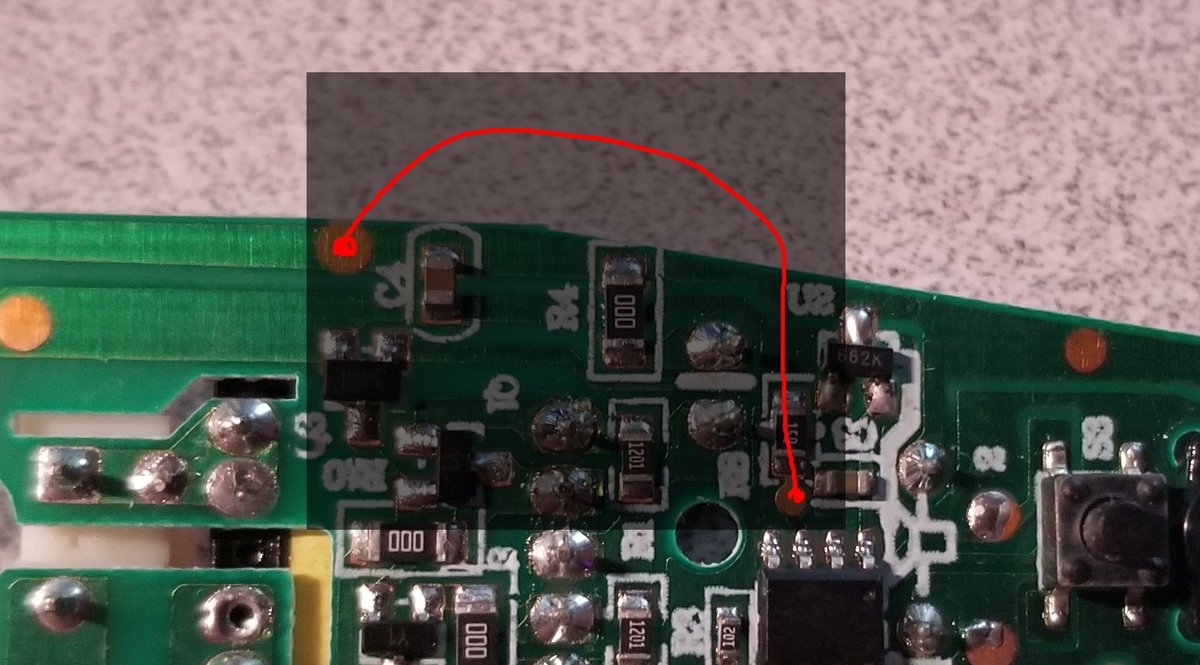

BTW, if you ever needed to control the lamp yourself by bypassing the microcontroller (which automatically turns itself off after 3 minutes), you'd do it by connecting these two test pads.

(Not that I'm saying you should ever do that)

(Not that I'm saying you should ever do that)

BTW, if you want to learn more about UV Lights and fakes, the youtuber Big Clive did a series of videos about them, which is where I learned about this sort of thing.

Here's an example video:

Here's an example video:

and you might have seen that I tweeted about buying "the wrong bananas".

What I did was get ones that were already ripe. I forgot at the time that it really needed to be green to have an obvious effect, so there was no noticeable change.

What I did was get ones that were already ripe. I forgot at the time that it really needed to be green to have an obvious effect, so there was no noticeable change.

possibly it would have worked if I had just waited long enough for the banana to over-ripen and then you'd see a difference between the exposed and unexposed areas, but by that point I had already devoured the evidence.

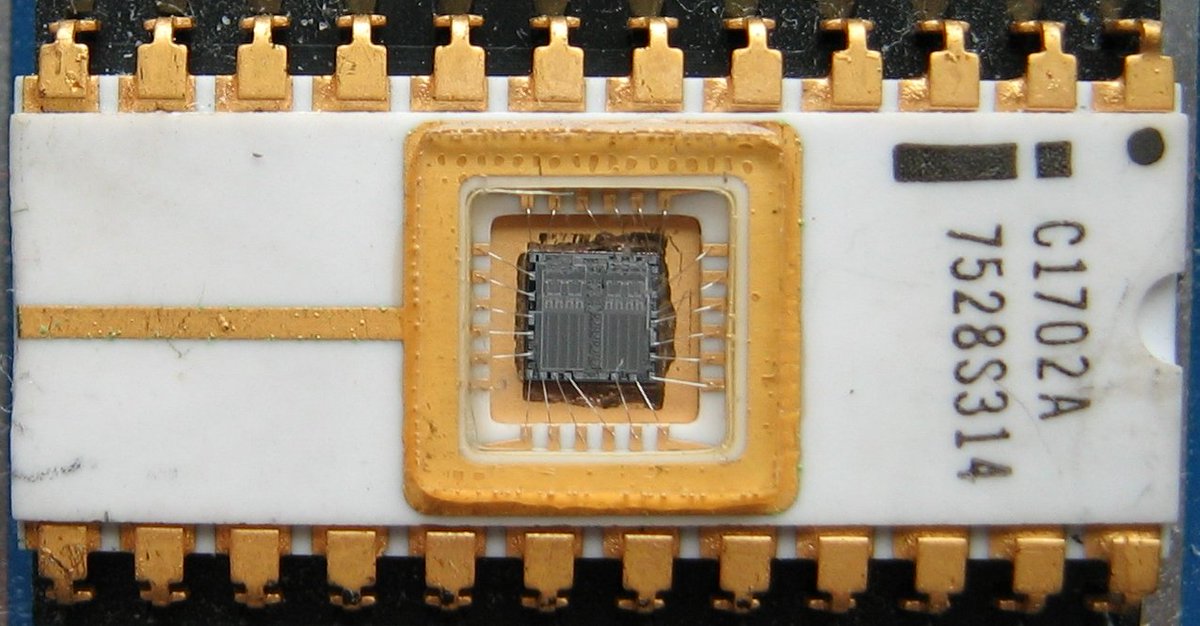

EPROMs are special chips where they're a bunch of floating-gate transistors, and by running a higher-than-usual voltage through them they trap charge in the transistor.

This lets them be programmed with data, and then it can be later read back off.

This lets them be programmed with data, and then it can be later read back off.

But this is a one-way process. You put data into it be programming some bits and by not programming others, so some are 1 and some are 0.

But you can't reset them back to unprogrammed... with electricity, at least.

But you can't reset them back to unprogrammed... with electricity, at least.

Because you probably noticed the distinctive feature of EPROMs: The window!

Instead of fully encapsulating the chip in ceramic, there's a little window of quartz above the chip.

Instead of fully encapsulating the chip in ceramic, there's a little window of quartz above the chip.

And by shining UV light into the chip, the silicon becomes ionized and the charge in these floating transistors will dissipate.

Basically you unprogram the whole chip using UV light, then reprogram it again using high voltage.

Basically you unprogram the whole chip using UV light, then reprogram it again using high voltage.

So these were very useful back in the day before EEPROMs and Flash memory, because you could repeatedly program and unprogram them, and in a circuit they worked like a mask ROM.

So like a development copy of a video game cartridge would usually include an EPROM, like this copy of Spanky's Quest for the Game Boy.

The developer would burn a copy of the game to the EPROM, test it, and then they'd erase it using a UV eraser.

The developer would burn a copy of the game to the EPROM, test it, and then they'd erase it using a UV eraser.

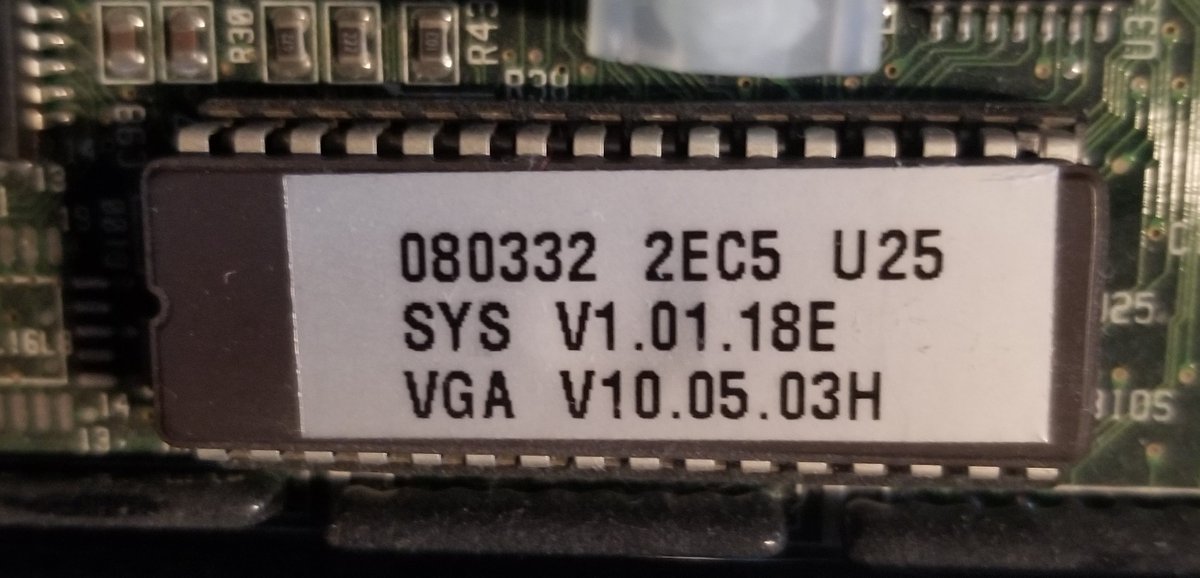

Another common place you'd see EPROMs was holding the BIOS of PCs, like this one for a Packard Bell 486.

EPROMs usually had stickers over them because it prevent any ambient light from affecting the chip.

EPROMs usually had stickers over them because it prevent any ambient light from affecting the chip.

so naturally you might wonder "can I use this disinfecting wand to erase EPROM chips?"

And the answer is... very probably.

And the answer is... very probably.

Wikipedia says the recommended erasure procedure is "UV light at 253.7 nm of at least 15 Ws/cm2, usually achieved in 20 to 30 minutes with the lamp at a distance of about 2.5 cm."

well, there's four things there:

1. Wavelength

2. Intensity

3. Time

4. Distance

1. Wavelength

2. Intensity

3. Time

4. Distance

As for wavelength, we know it's 254nm, which is probably identical to the 253.7 they mention. So it's perfect there.

Intensity may be the problem.

They say 15 watts per square centimeter... this is a 2 watt lamp. But probably that just means we'd need to wait longer.

They say 15 watts per square centimeter... this is a 2 watt lamp. But probably that just means we'd need to wait longer.

3. Time:

You wouldn't think time would be a problem, but it really is! The thing turns off every 3 minutes.

Even getting to the recommended 20-30 minutes would be annoying with it turning itself off every 3 minutes, let alone longer to make up for the lower intensity

You wouldn't think time would be a problem, but it really is! The thing turns off every 3 minutes.

Even getting to the recommended 20-30 minutes would be annoying with it turning itself off every 3 minutes, let alone longer to make up for the lower intensity

Finally, 4. distance: that's not gonna be a problem. The top of the wand doesn't really have any protection which means you could put the UV tube right up against the glass of the EPROM.

so as for the "can you erase EPROMs with it?" question, I'll say:

probably if you're patient and you bypass the timeout mechanism.

(I may have to test this later)

probably if you're patient and you bypass the timeout mechanism.

(I may have to test this later)

As for professional UV erasing, you'd have devices designed like this. Basically it's a fluorescent tube in a box, with a drawer and a timer.

You put the EPROMs in the drawer, then set the time. It runs the light for that long, and then rings a bell or sets off a buzzer.

You put the EPROMs in the drawer, then set the time. It runs the light for that long, and then rings a bell or sets off a buzzer.

for completeness, to explain if you're not a hardware person:

The alternatives to EPROMs are:

1. EEPROMs/Flash

2. OTP EPROMs

3. Mask ROM

The alternatives to EPROMs are:

1. EEPROMs/Flash

2. OTP EPROMs

3. Mask ROM

so EPROM stands for "Erasable Programmable Read Read Only Memory", and the EEPROM just adds "Eletrically" to the start.

Basically they have a similar floating-gate structure to EPROMs, but they can be erased without needing UV light, instead they use quantum tunneling.

Basically they have a similar floating-gate structure to EPROMs, but they can be erased without needing UV light, instead they use quantum tunneling.

EEPROM technology is what modern Flash memory is based on.

The kind used in SD cards and SSD hard drives.

They similarly are floating-gates which store charge, and different effects can be used to program and erase them.

The kind used in SD cards and SSD hard drives.

They similarly are floating-gates which store charge, and different effects can be used to program and erase them.

and OTP EPROMs are just a simple variation of EPROMs:

Basically, you just leave off the programming window.

This makes it cheaper, which is useful if you are shipping a bunch of them, but it means they can only be programmed once, thus OTP: One Time Programming

Basically, you just leave off the programming window.

This makes it cheaper, which is useful if you are shipping a bunch of them, but it means they can only be programmed once, thus OTP: One Time Programming

Then finally Mask ROMs:

This is where the data you want to store is encoded into the structure of the chip itself.

It can't be reprogrammed, it can't be changed, it'll basically last "forever".

This is where the data you want to store is encoded into the structure of the chip itself.

It can't be reprogrammed, it can't be changed, it'll basically last "forever".

But the thing about mask ROMs is that they have the lowest per-chip cost but the highest overhead cost, tens of thousands of dollars or more to design one.

Unlike an EPROM or EEPROM which can be programed with a device costing under a hundred dollars (today. obviously back in 1970-1980 it was more expensive).

Which makes mask ROMs perfect for things like video game cartridges.

Think about the costs of making a game like Super Mario Bros:

You're selling each cartridge for like 25$, so you want it to be cheap as possible.

Think about the costs of making a game like Super Mario Bros:

You're selling each cartridge for like 25$, so you want it to be cheap as possible.

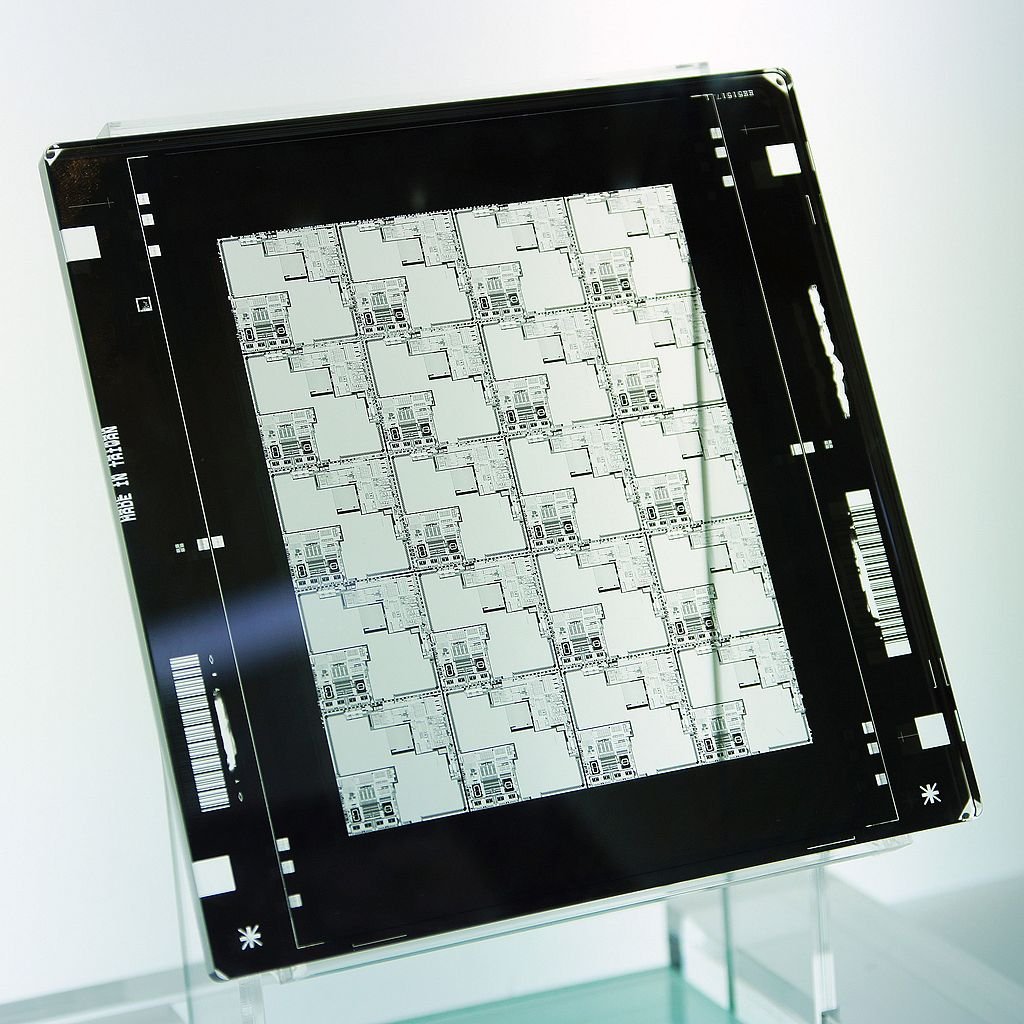

They're called "mask" ROMs because of how chips are made, using photolithography.

Basically a silicon wafer is prepared with a layer of photoresist, then light (often UV light!) is shined onto it.

Basically a silicon wafer is prepared with a layer of photoresist, then light (often UV light!) is shined onto it.

depending on the type of photoresist used (positive or negative), this either changes the photoresist layer to become soluble or prevents it from being soluble.

Then a developer is applied to the wafer, washing away the photoresist layer where it's soluble.

Then a developer is applied to the wafer, washing away the photoresist layer where it's soluble.

then an etching agent is used to remove a layer of the wafer. The photoresist prevents the etching agent from affecting the wafer where it's present, so you get a pattern on the wafer of places which were etched and places that weren't.

And where'd that pattern come from? from the light you shined on it earlier. You shined it on some places and not others.

But the way you do that is by having an intense focused light aimed at the wafer, and a mask placed in front of the wafer.

But the way you do that is by having an intense focused light aimed at the wafer, and a mask placed in front of the wafer.

The mask stops the light from hitting parts of the wafer and lets it through to other places, so essentially it's a template for that layer of the chip. Designing a mask is not cheap, which is why mask ROMs have the highest upfront cost.

The way these photomasks were made has changed over time, with the early ones being amazingly complex and manual. You'd design a chip on graph paper, then use a special machine to coordinate making cuts into Rubylith, a type of double-layered film.

This would produce a version of the photomask, but at a much larger size (like 100 times the size, so this would take up an entire wall).

It'd then be reduced down to the needed size using photolithography.

It'd then be reduced down to the needed size using photolithography.

Later, the process would get more automated as systems were developed to have computer-controlled photomask production, having the computer design drive an automatically controlled plotter to remove the top layer of Rubylith.

And more modern photomasks are done by directly drawing them into a photomask using electron-beam lithography.

Assuming a mask is used at all. See, there's also maskless lithography...

Assuming a mask is used at all. See, there's also maskless lithography...

Because if you can directly build a photomask by accurately steering an electron-beam, you could instead just use that same process (or a similar one: some are laser based instead of electron-beam) on the chip itself, bypassing the need for a mask.

Maskless lithography exists but doesn't seem to be that heavily used yet, as it's not as cheap or fast as more traditional systems, but it has a lot of promise.

ANYWAY this was supposed to be about bananas, not semiconductor fabrication.

So I'll shut up and point out that if you enjoyed this science thread,

1. be very careful with UV lights if you do your own experiments

So I'll shut up and point out that if you enjoyed this science thread,

1. be very careful with UV lights if you do your own experiments

2. feel free to send me a dollar or two on my ko-fi in thanks: https://ko-fi.com/fooneturing

or set up a monthly donation on my patreon: https://www.patreon.com/foone

Read on Twitter

Read on Twitter