Thread on Reshoring

Thread on ReshoringSome very smart people are using COVID-19 to point out our dependency on China-origin supply chains, and call for reshoring of manufacturing to the US.

Here's where the chokepoints in that are.

Some of my upcoming content will deal with solutions.

First, the US (and the West in general) is indeed dependent on the Far East/SE Asia manufacturing bases.

History and overview of this here:

2/ https://twitter.com/man_integrated/status/1231696281124397057

History and overview of this here:

2/ https://twitter.com/man_integrated/status/1231696281124397057

Relatedly, an incomprehensibly-vast logistics infrastructure has built up around the transpacific/transeurasian maritime routes.

The entire US logistics model is built along the same lines. We do import-to-receiver more efficiently than we do domestic-to-domestic shipping.

3/

The entire US logistics model is built along the same lines. We do import-to-receiver more efficiently than we do domestic-to-domestic shipping.

3/

Consider imports:

Ocean ship discharges at port. Container transfers to a drayman (container trucker) for local delivery.

If the cargo is going inland (to say, Chicago), it will mount to a unit train of ~200 containers.

At Chicago, it destows the train and is delivered.

4/

Ocean ship discharges at port. Container transfers to a drayman (container trucker) for local delivery.

If the cargo is going inland (to say, Chicago), it will mount to a unit train of ~200 containers.

At Chicago, it destows the train and is delivered.

4/

The entire FCL (full container load) import model is built around maximum operational efficiency of handling a 20' or 40' container, NOT the various pieces of freight inside it.

The packing, palletizing/loading, etc is all handled at origin by much cheaper labor.

5/

The packing, palletizing/loading, etc is all handled at origin by much cheaper labor.

5/

US importers, as the buyer, generally dictate how cargo is packaged.

Thus, they optimize for the least amount of rehandling on this end.

Usually, a package shipped in a container will arrive, move through the pipeline, and end up inventory exactly as it shipped from China.

6/

Thus, they optimize for the least amount of rehandling on this end.

Usually, a package shipped in a container will arrive, move through the pipeline, and end up inventory exactly as it shipped from China.

6/

But we can only optimize here because the marginal cost of logistics is reduced by transferring the labor-intensive tasks to the foreign shipper.

When US companies have to operate at both ends of the supply chain, it gets more expensive to pack/ship per unit.

7/

When US companies have to operate at both ends of the supply chain, it gets more expensive to pack/ship per unit.

7/

If the volume of product ordered from China is smaller, the freight will move in an LCL (less than container load) model.

Multiple smaller buyers will have their freight aggregated at origin, then shipped in a single container to the US, where it's delivered to a warehouse.

8/

Multiple smaller buyers will have their freight aggregated at origin, then shipped in a single container to the US, where it's delivered to a warehouse.

8/

These special warehouses, called deconsolidators, will pull all the freight off many containers and re-sort it by inland destination.

Then, the Chicago-bound freight is stuffed into a domestic 53' size container (standard US trailer length) and sent by rail to Chicago.

9/

Then, the Chicago-bound freight is stuffed into a domestic 53' size container (standard US trailer length) and sent by rail to Chicago.

9/

Once in Chicago, the container is taken to another special warehouse, called a Container Freight Station (CFS).

The CFS unloads and re-sorts the cargo by local customer.

Usually, the CFS also arranges for delivery as well.

Here again, though, it's all optimized.

10/

The CFS unloads and re-sorts the cargo by local customer.

Usually, the CFS also arranges for delivery as well.

Here again, though, it's all optimized.

10/

So far as most importers care, it's PFM (pure f***ing magic).

They order the goods from a factory in China, and it shows up at their door a month or so later.

Typically, the bottlenecks are customs clearance issues at the port/rail ramp, or dray capacity.

11/

They order the goods from a factory in China, and it shows up at their door a month or so later.

Typically, the bottlenecks are customs clearance issues at the port/rail ramp, or dray capacity.

11/

Now, this all works because EVERYTHING is made in China.

The raw materials for the goods (plastic, circuitry, metals, etc), the manufacturing equipment itself, the packaging, the coronavirus-air bubble wrap - all of it, made close to the origin of the goods.

12/

The raw materials for the goods (plastic, circuitry, metals, etc), the manufacturing equipment itself, the packaging, the coronavirus-air bubble wrap - all of it, made close to the origin of the goods.

12/

China controls the supply chains for the supply chain.

And for each part of that process, it increases the marginal cost to US companies to "buy American".

Our cardboard, pallets, and shrink wrap are all more costly.

Labor to pick/pack/load.

13/

And for each part of that process, it increases the marginal cost to US companies to "buy American".

Our cardboard, pallets, and shrink wrap are all more costly.

Labor to pick/pack/load.

13/

Further is the hidden cost of regulatory requirements.

China devalues human and environmental health to keep pumping out cheap goods.

Polluted air from cheap fossil fuel sources, plastics manufacturing polluting the waters, and so on.

Sometimes, things like this happen...

14/

China devalues human and environmental health to keep pumping out cheap goods.

Polluted air from cheap fossil fuel sources, plastics manufacturing polluting the waters, and so on.

Sometimes, things like this happen...

14/

The US has had its own troubles with chemical and fertilizer explosions, but the incidents are far less frequent thanks to aggressive regulatory oversight by EPA, OSHA, PHMSA, and other agencies.

But however important and necessary, these regulations still cost big $$.

15/

But however important and necessary, these regulations still cost big $$.

15/

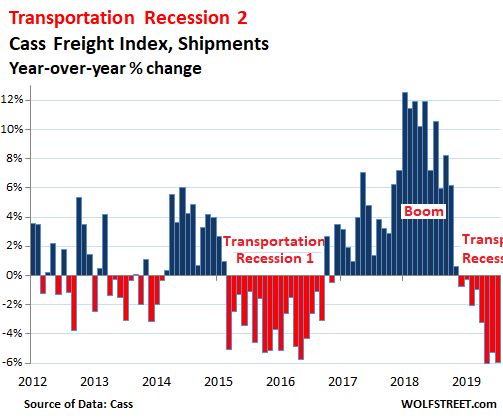

In addition, and perhaps most importantly, our domestic logistics capacity is a disaster.

Nearly all indicators are negative and trending further the wrong way.

Primarily, the US relies on trucks and trains to get cargo from A to B.

16/

Nearly all indicators are negative and trending further the wrong way.

Primarily, the US relies on trucks and trains to get cargo from A to B.

16/

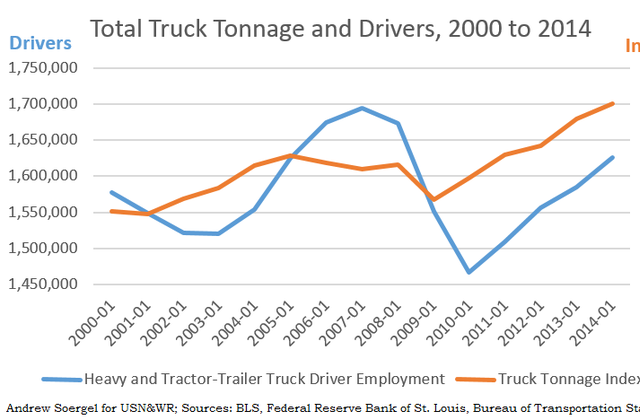

Trucking has a manpower crisis. The average age of drivers has risen in the past decade, with correlated increases in benefits, medical expenses, and per-freight-mile cost.

In addition, new Dept of Transportation requirements on driver service hours has taken a toll.

17/

In addition, new Dept of Transportation requirements on driver service hours has taken a toll.

17/

Though that graph above is from 2014, the trend has only accelerated.

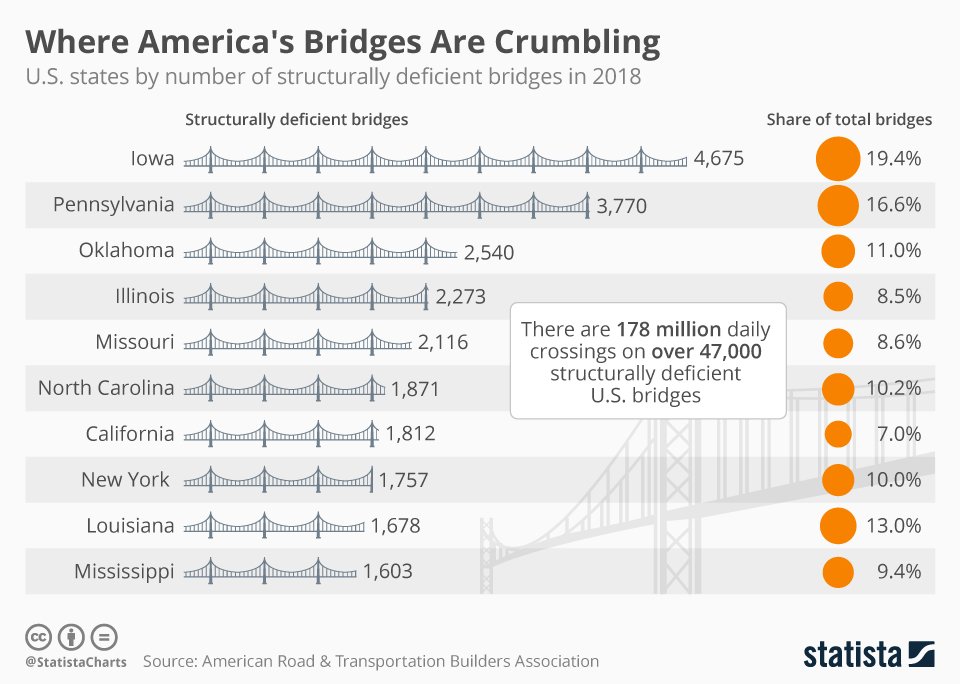

There's more freight than trucks, carried on crumbling highways and bridges, by drivers rapidly increasing in age.

Lastly, trucking is very sensitive to fuel prices.

Increases there have direct impact.

18/

There's more freight than trucks, carried on crumbling highways and bridges, by drivers rapidly increasing in age.

Lastly, trucking is very sensitive to fuel prices.

Increases there have direct impact.

18/

The rail industry is in no better shape.

The challenges facing the trucking industry have caused many shippers to switch to intermodal (domestic container-on-rail) shipping, where the only trucking component is the first and final miles (better capacity).

However........

19/

The challenges facing the trucking industry have caused many shippers to switch to intermodal (domestic container-on-rail) shipping, where the only trucking component is the first and final miles (better capacity).

However........

19/

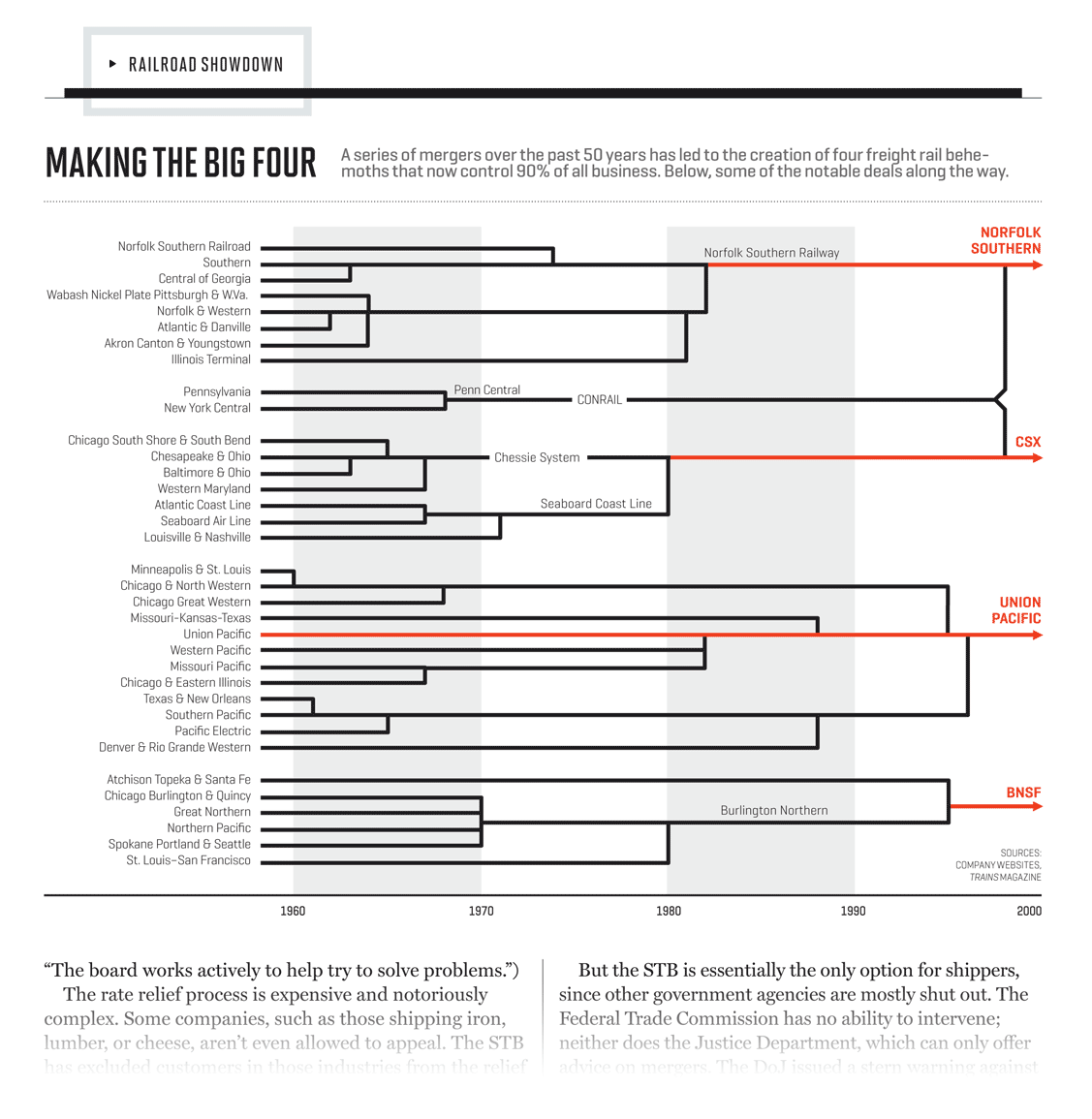

Rail is facing its own structural issues.

Cost of newbuild and repair per rail mile has increased dramatically.

In response, Class 1 railroads have moved to "precision railroading", which basically means eliminating the spider web of smaller rail-served locations.

20/

Cost of newbuild and repair per rail mile has increased dramatically.

In response, Class 1 railroads have moved to "precision railroading", which basically means eliminating the spider web of smaller rail-served locations.

20/

This limiting of lanes to just major points means that Class 1's have transferred the burden of short-mile service (the most expensive and inefficient part of railroading) to shortline railroads that service local niche markets.

Consolidation is the only way to survive.

21/

Consolidation is the only way to survive.

21/

As with any oligopoly, the powerful few assert greater control.

The once-large cost efficiency of rail versus trucking has narrowed as fewer railroads take more revenues and deselect customers/locations that don't fit an optimal network design.

22/

The once-large cost efficiency of rail versus trucking has narrowed as fewer railroads take more revenues and deselect customers/locations that don't fit an optimal network design.

22/

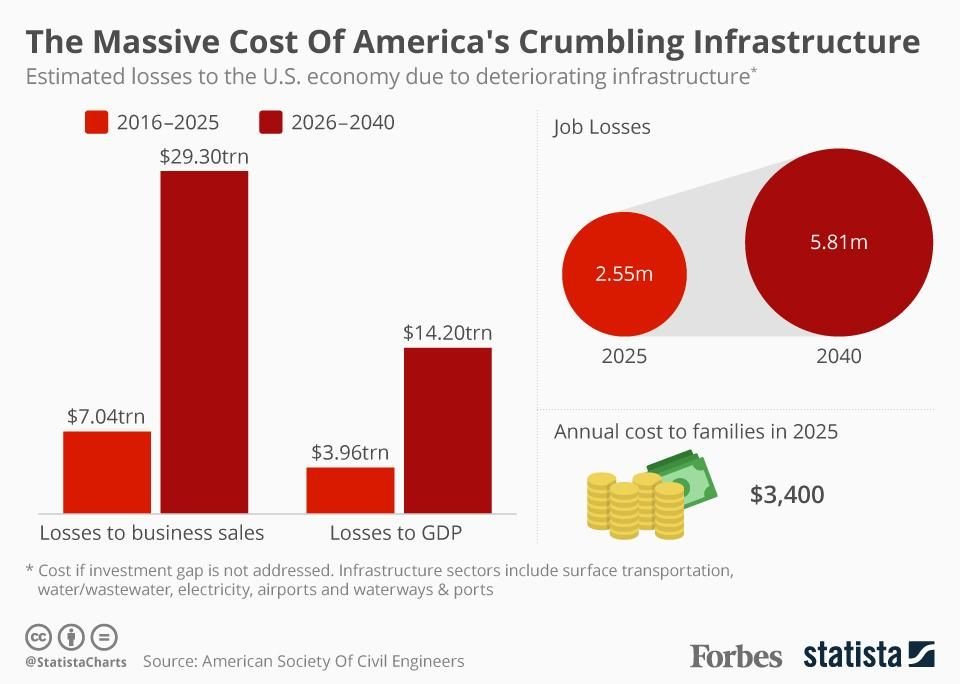

Finally, a word on infrastructure, once one of the US' greatest economic strengths.

These days, the US is a dumpster fire.

From roads to bridges to rail to airports to energy services, we are undercapitalized and underbuilt.

It's way past time to treat this as crisis.

23/

These days, the US is a dumpster fire.

From roads to bridges to rail to airports to energy services, we are undercapitalized and underbuilt.

It's way past time to treat this as crisis.

23/

Read on Twitter

Read on Twitter